Information injection-pump assembly

BOSCH

F 01G 09U 09B

f01g09u09b

ZEXEL

106693-6221

1066936221

ISUZU

8943905971

8943905971

Rating:

Service parts 106693-6221 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94390-519-0

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

14.

NOZZLE

Include in #1:

106693-6221

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 09U 09B

f01g09u09b

ZEXEL

106693-6221

1066936221

ISUZU

8943905971

8943905971

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8620

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.57

3.63

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

107

105

109

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

470

470

470

Average injection quantity

mm3/st.

12.5

9.3

15.7

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.7)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

107

106

108

Basic

*

Fixing the lever

*

Boost pressure

kPa

68.6

68.6

Boost pressure

mmHg

515

515

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.75

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

105.5

101.5

109.5

Fixing the lever

*

Boost pressure

kPa

68.6

68.6

Boost pressure

mmHg

515

515

Boost compensator adjustment

Pump speed

r/min

510

510

510

Rack position

R2-1.55

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_02

Pump speed

r/min

510

510

510

Rack position

R2[R1-0.

2]

Boost pressure

kPa

55.3

55.3

55.3

Boost pressure

mmHg

415

415

415

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Load

3/5

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.3

Load

3/5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1.5

1

2

Load

3/5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1075

Advance angle

deg.

1.5

1

2

Load

4/5

Timer adjustment_05

Pump speed

r/min

1350

Advance angle

deg.

5.5

5

6

Load

4/5

Remarks

Finish

Finish

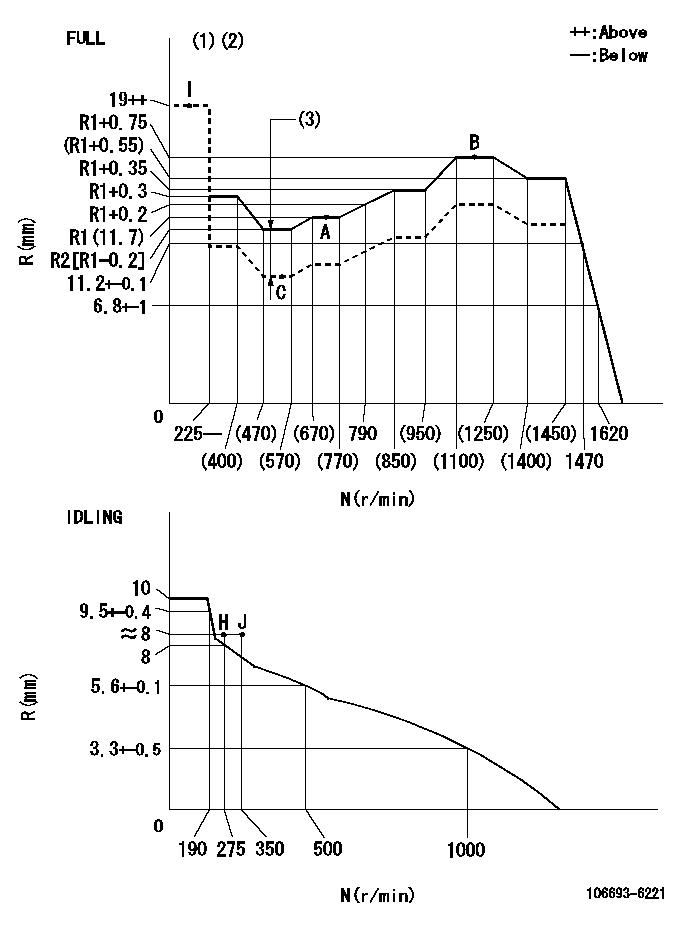

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AD90 BCL=1.55+-0.1mm

----------

----------

T1=AD90 BCL=1.55+-0.1mm

----------

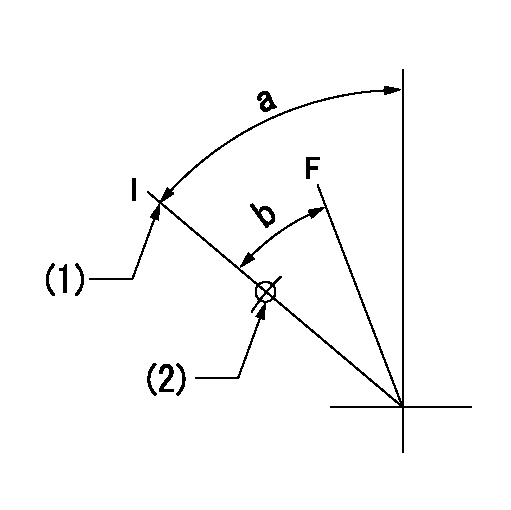

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=35mm

----------

a=64deg+-5deg b=35.5deg+-3deg

----------

aa=35mm

----------

a=64deg+-5deg b=35.5deg+-3deg

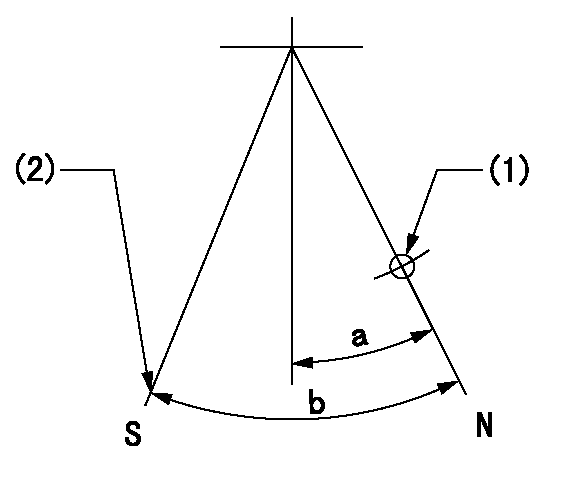

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt at rack position = bb, speed = cc and confirm non-injection.

----------

aa=55mm bb=1.5+-0.3mm cc=0r/min

----------

a=14deg+-5deg b=44deg+-5deg

----------

aa=55mm bb=1.5+-0.3mm cc=0r/min

----------

a=14deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7deg

----------

a=(50deg)

----------

aa=7deg

----------

a=(50deg)

Information:

This Program can only be administeredafter a failure occurs. The decision whether to apply the Program is madeby the dealer. When reporting the repair, use "PS50780" as the Part numberand "7755" as the Group Number. Use "96" as the Warranty Claim DescriptionCode and use "Z" as the SIMS Description Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst. This Revised Service Letter replacesthe April 2, 2004 (Revised April 2004) Service Letter. Changes have beenmade to the Affected Product.TERMINATION DATE

April 30, 2006PROBLEM

Failed injector and wiring harness need to bereplaced on certain C-9 Industrial Engines. The C-9 engine can developan injector misfire due to an open connection at the injector to harnessconnector. This misfire can be diagnosed with standard troubleshootingguide procedures.AFFECTED PRODUCT

Model Identification Number

C9 CLJ1-4259

12H 12500001-40AMZ1-496CBK1-353

330C B1K1-178B2L1-203B4N1-187BTM1-189CGZ1-511CYA1-287D3C1-231JAB1-626JCD1-292JNK1-245KDD1-580MCA1-427MKM1-308GAG1-329RBH1-233

330C L CAP1-1257DKY1-2011HAA1-393

D6R II AEM1-100AFM1-115BLE1-199BLT1-186BMK1-121BNL1-99BPM1-101BPP1-97BPS1-102BRJ1-116

D6R II LGP ACJ1-101ADE1-311BNC1-265BPZ1-142

D6R II XL AAX1-465BMJ1-130BMY1-297BRZ1-115CAD1-143FDT1-141

D6R II XW AEP1-223DAE1-129

470 7651-811

475 7671-824

MT765 AMS1-266

TK711 10100001-00191

TK721 10200001-00191

TK722 10300001-00193

TK732 10400185-00190

627G CEX187-296

637G CEH222-255PARTS NEEDED

Qty

Part Number

Description

1 1567106 Wiring Kit

1 1889865 Harness Assembly

1 2359651 Bolt - Socket

1 2360962 Injector GroupACTION REQUIRED

Replace the single failed injector with the new 2360962 Injector and the1889865 Wiring Harness Assembly. Refer to REHS1809 Special Instructionfor use of the 1567106 Wiring Kit.SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs Parts Labor Hrs Parts Labor Hrs

0-5000

0-35 months 100% 2.0 0 0 0 0

This is a 2?hour job.PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warrantyparts handling.

April 30, 2006PROBLEM

Failed injector and wiring harness need to bereplaced on certain C-9 Industrial Engines. The C-9 engine can developan injector misfire due to an open connection at the injector to harnessconnector. This misfire can be diagnosed with standard troubleshootingguide procedures.AFFECTED PRODUCT

Model Identification Number

C9 CLJ1-4259

12H 12500001-40AMZ1-496CBK1-353

330C B1K1-178B2L1-203B4N1-187BTM1-189CGZ1-511CYA1-287D3C1-231JAB1-626JCD1-292JNK1-245KDD1-580MCA1-427MKM1-308GAG1-329RBH1-233

330C L CAP1-1257DKY1-2011HAA1-393

D6R II AEM1-100AFM1-115BLE1-199BLT1-186BMK1-121BNL1-99BPM1-101BPP1-97BPS1-102BRJ1-116

D6R II LGP ACJ1-101ADE1-311BNC1-265BPZ1-142

D6R II XL AAX1-465BMJ1-130BMY1-297BRZ1-115CAD1-143FDT1-141

D6R II XW AEP1-223DAE1-129

470 7651-811

475 7671-824

MT765 AMS1-266

TK711 10100001-00191

TK721 10200001-00191

TK722 10300001-00193

TK732 10400185-00190

627G CEX187-296

637G CEH222-255PARTS NEEDED

Qty

Part Number

Description

1 1567106 Wiring Kit

1 1889865 Harness Assembly

1 2359651 Bolt - Socket

1 2360962 Injector GroupACTION REQUIRED

Replace the single failed injector with the new 2360962 Injector and the1889865 Wiring Harness Assembly. Refer to REHS1809 Special Instructionfor use of the 1567106 Wiring Kit.SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs Parts Labor Hrs Parts Labor Hrs

0-5000

0-35 months 100% 2.0 0 0 0 0

This is a 2?hour job.PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warrantyparts handling.