Information injection-pump assembly

ZEXEL

106693-6182

1066936182

ISUZU

8943953682

8943953682

Rating:

Cross reference number

ZEXEL

106693-6182

1066936182

ISUZU

8943953682

8943953682

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8620

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.57

3.63

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

108

106

110

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

12.5

9.3

15.7

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

108

107

109

Basic

*

Fixing the lever

*

Boost pressure

kPa

72

72

Boost pressure

mmHg

540

540

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

108

104

112

Fixing the lever

*

Boost pressure

kPa

72

72

Boost pressure

mmHg

540

540

Boost compensator adjustment

Pump speed

r/min

525

525

525

Rack position

R2-1.7

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_02

Pump speed

r/min

525

525

525

Rack position

R1-0.2(R

2)

Boost pressure

kPa

58.7

58.7

58.7

Boost pressure

mmHg

440

440

440

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Load

3/5

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.3

Load

3/5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1.5

1

2

Load

3/5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1075

Advance angle

deg.

1.5

1

2

Load

4/5

Timer adjustment_05

Pump speed

r/min

1350

Advance angle

deg.

5.5

5

6

Load

4/5

Remarks

Finish

Finish

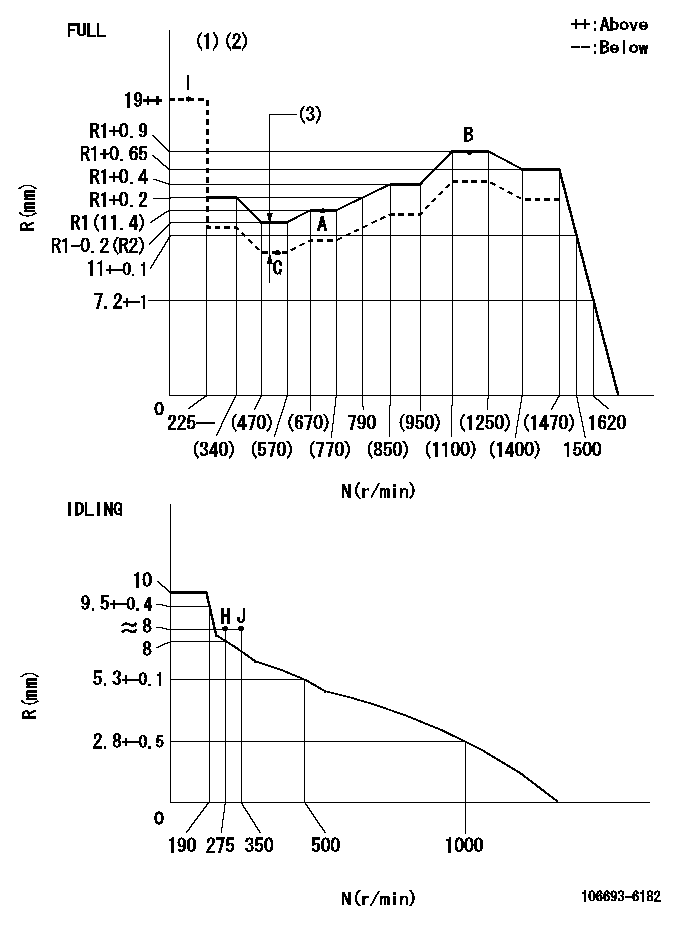

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AC30 BCL=1.7+-0.1mm

----------

----------

T1=AC30 BCL=1.7+-0.1mm

----------

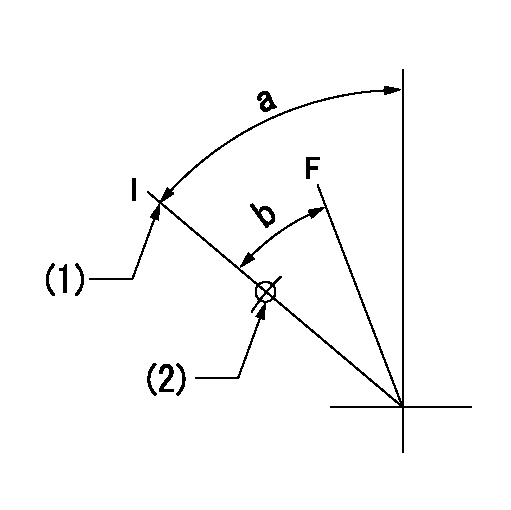

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=35mm

----------

a=64deg+-5deg b=38deg+-3deg

----------

aa=35mm

----------

a=64deg+-5deg b=38deg+-3deg

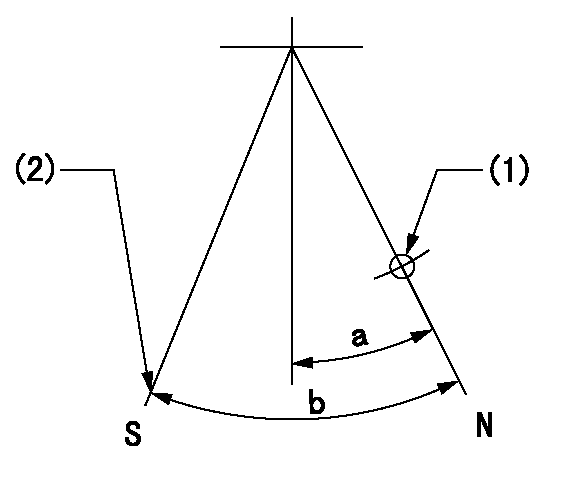

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt at rack position = bb, speed = cc and confirm non-injection.

----------

aa=55mm bb=1.5+-0.3mm cc=0r/min

----------

a=14deg+-5deg b=44deg+-5deg

----------

aa=55mm bb=1.5+-0.3mm cc=0r/min

----------

a=14deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7deg

----------

a=(50deg)

----------

aa=7deg

----------

a=(50deg)

Information:

(1) Tension of brush spring ... 80 to 90 oz.(2.27 to 2.55 kg)(2) Torque for bolts ... 8 lb. ft.(1.11 mkg)(3) Torque for terminal nuts ... 20 to 25 lb. ft.(2.8 to 3.5 mkg)(4) Clearance for the pinion ... .020 to .050 in.(0.51 to 1.27 mm)2P6162 24V (Prestolite Number MES 6301 K) 3P110 24V (Prestolite Number MFY 6401 I)

Rotation is clockwise when seen from drive end.Minimum speed with no load ... 5000 rpmCurrent consumption (draw) with no load: Maximum at 20 V ... 77 A(1) Tension of brush spring ... 80 to 90 oz.(2.27 to 2.55 kg)(2) Torque for housing bolts ... 8 lb. ft.(1.11 mkg)(3) Torque for terminal nuts ... 20 to 25 lb. ft.(2.8 to 3.5 mkg)(4) Clearance between pinion and housing (pinion clearance) ... .020 to .050 in.(0.51 to 1.27 mm)2P2502 24V (Delco-Remy Number 1113393)

Rotation is clockwise when seen from drive end. Minimum speed with no load ... 5500 rpmMaximum speed with no load ... 7500 rpmCurrent consumption (draw) at no load: Minimum with solenoid at 20 V ... 92.5 AMaximum with solenoid at 20 V ... 120.1 AClearance between pinion and housing (pinion clearance) ... .36 in.(9.1 mm) (1) Tension of brush spring* ... 36 to 40 oz.(1.01 to 1.14 kg)(2) Torque for terminal nuts ... 20 to 25 lb. ft.(2.8 to 3.5 mkg) ... 80 oz.(2.27 kg)*Minimum for leaf springs 4N3182 24V (Delco-Remy Number 1114711)

Rotation is clockwise when seen from drive end.Minimum speed with no load ... 5500 rpmMaximum speed with no load ... 7500 rpmCurrent consumption (draw) at no load: Minimum with solenoid at 20V ... 108.5 AMaximum with solenoid at 20V ... 135.1 AClearance between pinion and housing (pinion clearance) ... .36 in.(9.1 mm) (1) Tension of brush spring ... 80 oz.(2.26 kg)(2) Torque for screws holding nose housing to lever housing ... 13 to 17 lb. ft.(1.8 to 2.4 mkg)(3) Torque for terminal nuts ... 20 to 25 lb. ft.(2.8 to 3.5 mkg)

Rotation is clockwise when seen from drive end.Minimum speed with no load ... 5000 rpmCurrent consumption (draw) with no load: Maximum at 20 V ... 77 A(1) Tension of brush spring ... 80 to 90 oz.(2.27 to 2.55 kg)(2) Torque for housing bolts ... 8 lb. ft.(1.11 mkg)(3) Torque for terminal nuts ... 20 to 25 lb. ft.(2.8 to 3.5 mkg)(4) Clearance between pinion and housing (pinion clearance) ... .020 to .050 in.(0.51 to 1.27 mm)2P2502 24V (Delco-Remy Number 1113393)

Rotation is clockwise when seen from drive end. Minimum speed with no load ... 5500 rpmMaximum speed with no load ... 7500 rpmCurrent consumption (draw) at no load: Minimum with solenoid at 20 V ... 92.5 AMaximum with solenoid at 20 V ... 120.1 AClearance between pinion and housing (pinion clearance) ... .36 in.(9.1 mm) (1) Tension of brush spring* ... 36 to 40 oz.(1.01 to 1.14 kg)(2) Torque for terminal nuts ... 20 to 25 lb. ft.(2.8 to 3.5 mkg) ... 80 oz.(2.27 kg)*Minimum for leaf springs 4N3182 24V (Delco-Remy Number 1114711)

Rotation is clockwise when seen from drive end.Minimum speed with no load ... 5500 rpmMaximum speed with no load ... 7500 rpmCurrent consumption (draw) at no load: Minimum with solenoid at 20V ... 108.5 AMaximum with solenoid at 20V ... 135.1 AClearance between pinion and housing (pinion clearance) ... .36 in.(9.1 mm) (1) Tension of brush spring ... 80 oz.(2.26 kg)(2) Torque for screws holding nose housing to lever housing ... 13 to 17 lb. ft.(1.8 to 2.4 mkg)(3) Torque for terminal nuts ... 20 to 25 lb. ft.(2.8 to 3.5 mkg)