Information injection-pump assembly

ZEXEL

106693-6164

1066936164

ISUZU

8943900460

8943900460

Rating:

Service parts 106693-6164 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94390-049-1

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}/22.1{225}

15.

NOZZLE SET

Include in #1:

106693-6164

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106693-6164

1066936164

ISUZU

8943900460

8943900460

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8620

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.57

3.63

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

108

106

110

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

12.5

9.3

15.7

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

108

107

109

Basic

*

Fixing the lever

*

Boost pressure

kPa

72

72

Boost pressure

mmHg

540

540

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

108

104

112

Fixing the lever

*

Boost pressure

kPa

72

72

Boost pressure

mmHg

540

540

Boost compensator adjustment

Pump speed

r/min

525

525

525

Rack position

R2-1.7

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_02

Pump speed

r/min

525

525

525

Rack position

R1-0.2(R

2)

Boost pressure

kPa

58.7

58.7

58.7

Boost pressure

mmHg

440

440

440

Timer adjustment

Pump speed

r/min

900

Advance angle

deg.

0

0

0

Load

3/5

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.3

Load

3/5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1.5

1

2

Load

3/5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1075

Advance angle

deg.

1.5

1

2

Load

4/5

Timer adjustment_05

Pump speed

r/min

1350

Advance angle

deg.

5.5

5

6

Load

4/5

Remarks

Finish

Finish

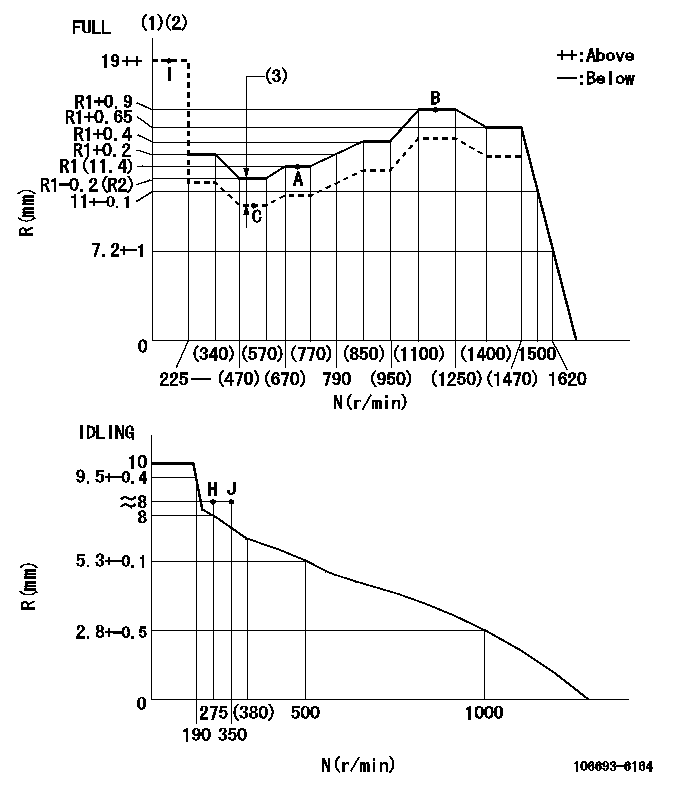

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AC30 BCL=1.7+-0.1mm

----------

----------

T1=AC30 BCL=1.7+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=20deg+-5deg b=38deg+-3deg

----------

aa=35mm

----------

a=20deg+-5deg b=38deg+-3deg

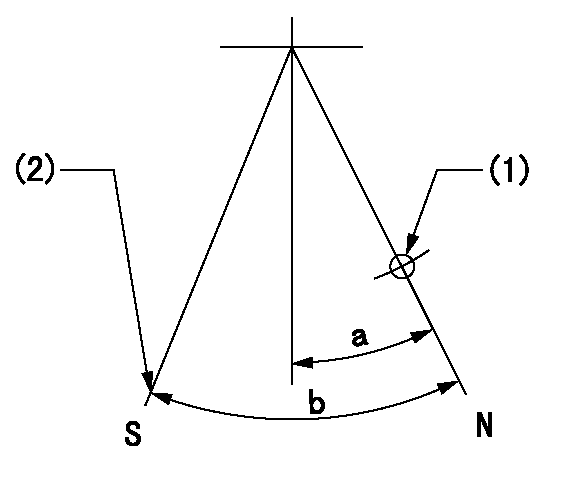

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt at rack position = bb, speed = cc and confirm non-injection.

----------

aa=40mm bb=1.5+-0.3mm cc=0r/min

----------

a=12deg+-5deg b=44deg+-5deg

----------

aa=40mm bb=1.5+-0.3mm cc=0r/min

----------

a=12deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7deg

----------

a=(50deg)

----------

aa=7deg

----------

a=(50deg)

Information:

Adjusting the engine speeds

To adjust engine speed, remove the cooling fan and install the safety cover over the fan to prevent getting hurt. For speed adjustment specification, see 8-05.(1) The upper limit of engine speed can be adjusted with the HIGH-SPEED stopper bolt.This stopper bolt has been set properly and sealed in the factory before shipping of the engine. Never tamper with the seal unless it is necessary.(2) The lower limit of engine speed can be adjusted with the LOW-SPEED stopper bolt.(3) Never remove the sealing cap unnecessarily to adjust the torque spring set. For the proper disassembling procedure, see 4-02. CAUTION Warm up the engine (until coolant temperature rises up to 60°C or above) before adjusting engine speeds.(4) During running of the engine for speed adjustment, check the engine for gas leak, water leak, oil leak, and fuel leak.(5) After adjustment, perform engine acceleration and deceleration test to confirm that the engine is free from hunting and smoking.

HIGH-SPEED and LOW-SPEED Set BoltsChecking and adjustment of nozzles

To check and adjust the injection nozzles, use the following procedure:1. Injection start pressure(1) Remove the nozzle assembly to be tested from the cylinder head and set the nozzle on the nozzle tester.Perform air bleeding by moving the tester handle up and down.(2) Operate the handle at a speed of 60 rpm or more and read the gauge pressure of fuel injected from the nozzle.* Injection start pressure: 140 +10-0kgf/cm2 [13.7+1.0-0 MPa(3) If reading of gauge pressure is not within the specified range, disassemble the nozzle and vary thickness of the adjusting shim.Increasing or decreasing shim thickness by 0.1 mm will cause injection pressure to vary about 10 kgf/cm2 [0.98 MPa]

Testing Injection Start Pressure(4) When installing the nozzle, use the following values of tightening torque:* Nozzle tightening (to cylinder head) torque: 5.0 - 6.0 kgf m [49 - 59 N m]* Nozzle retaining nut tightening torque: 3.5 - 4.0 kgf m [34 - 39 N m]* Nozzle union collar tightening torque: 2.5 - 3.0 kgf m [25 - 29 N m]

Installing Nozzle Assembly2. Chattering testOperate the tester handle at a speed of about 1 stroke per second.(1) Needle valve oscillationIt is considered normal if the nozzle injects fuel mist, making intermittent sounds, and oscillations of the needle valve are transmitted to the handle.(2) State of fuel mist injectionThe nozzle should inject fuel mist straight in the direction of its axis. A nozzle is defective if it does not inject steadily or it injects fuel in several separate stripes.A nozzle is defective if it spills fuel accumulated on the bottom of the nozzle after chattering test. However, a very small drop of fuel remaining on the tip of nozzle after chattering test may be regarded as normal.

Charttering Test

After-spilling3. Injection testOperate the tester handle at a speed of 4 to 6 strokes per second.* A nozzle should inject fuel mist uniformly in the shape of a cone.4. Checking the compression pressure(1) Make sure of the following:(a) All of the engine oil level, air cleaner,

To adjust engine speed, remove the cooling fan and install the safety cover over the fan to prevent getting hurt. For speed adjustment specification, see 8-05.(1) The upper limit of engine speed can be adjusted with the HIGH-SPEED stopper bolt.This stopper bolt has been set properly and sealed in the factory before shipping of the engine. Never tamper with the seal unless it is necessary.(2) The lower limit of engine speed can be adjusted with the LOW-SPEED stopper bolt.(3) Never remove the sealing cap unnecessarily to adjust the torque spring set. For the proper disassembling procedure, see 4-02. CAUTION Warm up the engine (until coolant temperature rises up to 60°C or above) before adjusting engine speeds.(4) During running of the engine for speed adjustment, check the engine for gas leak, water leak, oil leak, and fuel leak.(5) After adjustment, perform engine acceleration and deceleration test to confirm that the engine is free from hunting and smoking.

HIGH-SPEED and LOW-SPEED Set BoltsChecking and adjustment of nozzles

To check and adjust the injection nozzles, use the following procedure:1. Injection start pressure(1) Remove the nozzle assembly to be tested from the cylinder head and set the nozzle on the nozzle tester.Perform air bleeding by moving the tester handle up and down.(2) Operate the handle at a speed of 60 rpm or more and read the gauge pressure of fuel injected from the nozzle.* Injection start pressure: 140 +10-0kgf/cm2 [13.7+1.0-0 MPa(3) If reading of gauge pressure is not within the specified range, disassemble the nozzle and vary thickness of the adjusting shim.Increasing or decreasing shim thickness by 0.1 mm will cause injection pressure to vary about 10 kgf/cm2 [0.98 MPa]

Testing Injection Start Pressure(4) When installing the nozzle, use the following values of tightening torque:* Nozzle tightening (to cylinder head) torque: 5.0 - 6.0 kgf m [49 - 59 N m]* Nozzle retaining nut tightening torque: 3.5 - 4.0 kgf m [34 - 39 N m]* Nozzle union collar tightening torque: 2.5 - 3.0 kgf m [25 - 29 N m]

Installing Nozzle Assembly2. Chattering testOperate the tester handle at a speed of about 1 stroke per second.(1) Needle valve oscillationIt is considered normal if the nozzle injects fuel mist, making intermittent sounds, and oscillations of the needle valve are transmitted to the handle.(2) State of fuel mist injectionThe nozzle should inject fuel mist straight in the direction of its axis. A nozzle is defective if it does not inject steadily or it injects fuel in several separate stripes.A nozzle is defective if it spills fuel accumulated on the bottom of the nozzle after chattering test. However, a very small drop of fuel remaining on the tip of nozzle after chattering test may be regarded as normal.

Charttering Test

After-spilling3. Injection testOperate the tester handle at a speed of 4 to 6 strokes per second.* A nozzle should inject fuel mist uniformly in the shape of a cone.4. Checking the compression pressure(1) Make sure of the following:(a) All of the engine oil level, air cleaner,