Information injection-pump assembly

ZEXEL

106693-6162

1066936162

ISUZU

8943949462

8943949462

Rating:

Service parts 106693-6162 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94394-213-0

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}/22.1{225}

15.

NOZZLE SET

Include in #1:

106693-6162

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106693-6162

1066936162

ISUZU

8943949462

8943949462

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8620

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.57

3.63

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

108

106

110

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

12.5

9.3

15.7

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

108

107

109

Basic

*

Fixing the lever

*

Boost pressure

kPa

72

72

Boost pressure

mmHg

540

540

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

108

104

112

Fixing the lever

*

Boost pressure

kPa

72

72

Boost pressure

mmHg

540

540

Boost compensator adjustment

Pump speed

r/min

525

525

525

Rack position

R2-1.7

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_02

Pump speed

r/min

525

525

525

Rack position

R1-0.2(R

2)

Boost pressure

kPa

58.7

58.7

58.7

Boost pressure

mmHg

440

440

440

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Load

3/5

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.3

Load

3/5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1.5

1

2

Load

3/5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1075

Advance angle

deg.

1.5

1

2

Load

4/5

Timer adjustment_05

Pump speed

r/min

1350

Advance angle

deg.

5.5

5

6

Load

4/5

Remarks

Finish

Finish

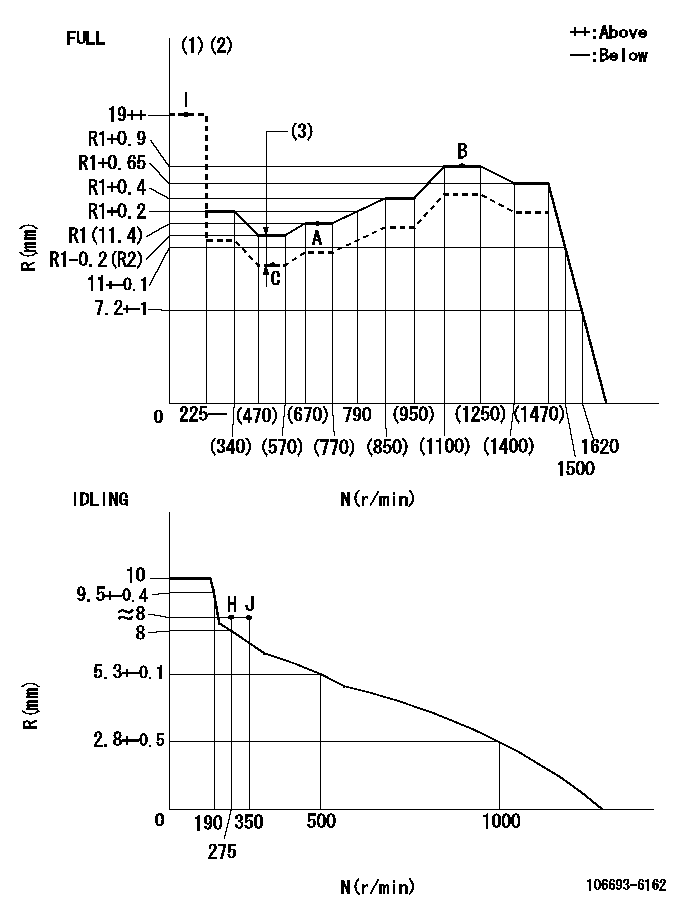

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AC30 BCL=1.7+-0.1mm

----------

----------

T1=AC30 BCL=1.7+-0.1mm

----------

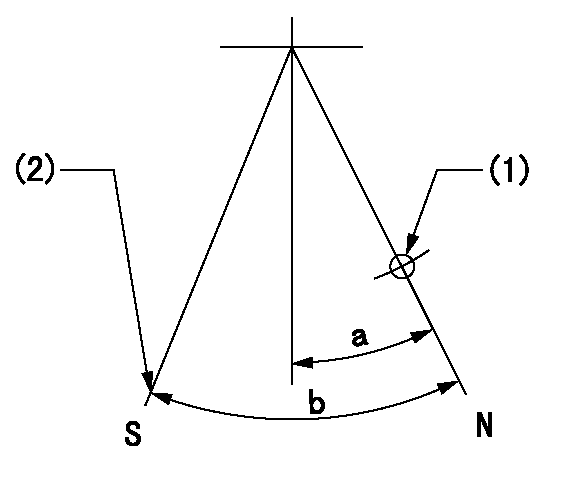

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=20deg+-5deg b=38deg+-3deg

----------

aa=35mm

----------

a=20deg+-5deg b=38deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt at rack position = bb, speed = cc and confirm non-injection.

----------

aa=40mm bb=1.5+-0.3mm cc=0r/min

----------

a=12deg+-5deg b=44deg+-5deg

----------

aa=40mm bb=1.5+-0.3mm cc=0r/min

----------

a=12deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7deg

----------

a=(50deg)

----------

aa=7deg

----------

a=(50deg)

Information:

Disassembly and Reassembly of General Parts

Oil seals

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.

Oil seals

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.