Information injection-pump assembly

ZEXEL

106693-6110

1066936110

ISUZU

1156028910

1156028910

Rating:

Service parts 106693-6110 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.1(225)

15.

NOZZLE SET

Include in #1:

106693-6110

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106693-6110

1066936110

ISUZU

1156028910

1156028910

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

133.9

131.9

135.9

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.3+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.4

15.8

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Timer adjustment

Pump speed

r/min

(830)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

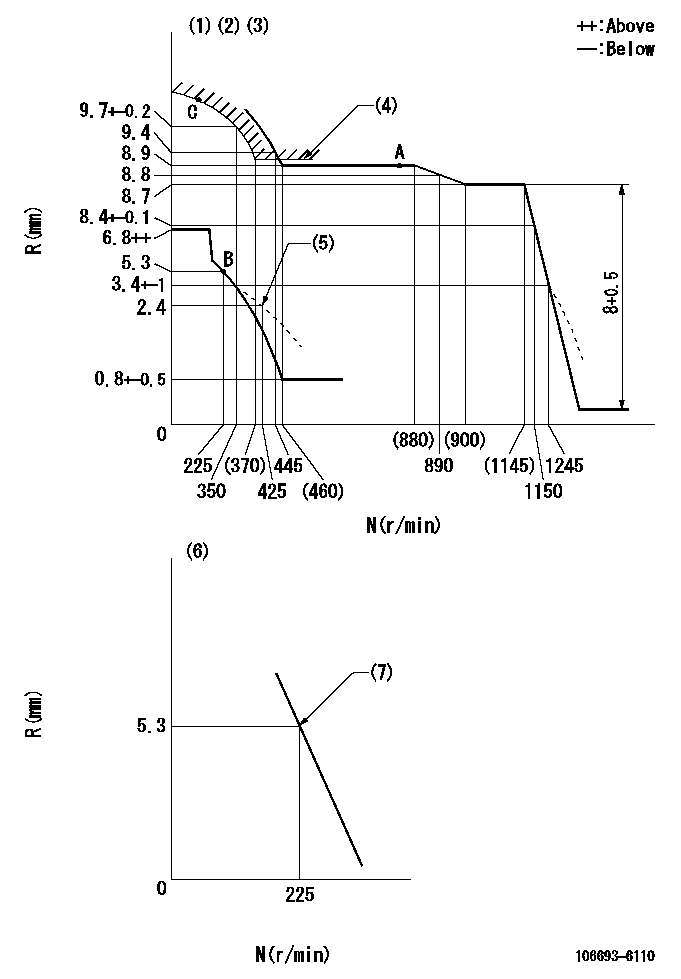

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Excess fuel setting for starting: SXL

(5)Damper spring setting

(6)Variable speed specification: idling adjustment

(7)Main spring setting

----------

RT=1 TH=1.7mm SXL=9.2+-0.1mm

----------

----------

RT=1 TH=1.7mm SXL=9.2+-0.1mm

----------

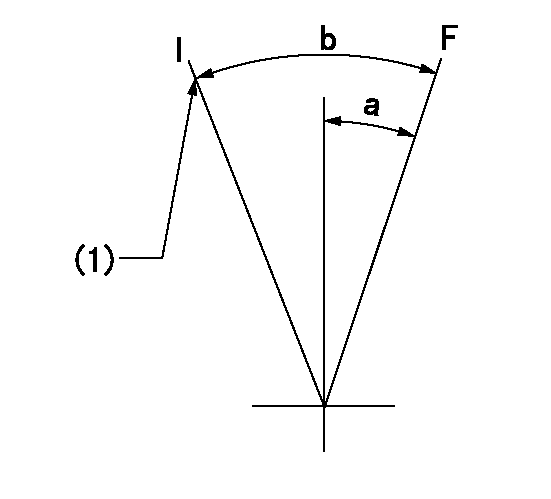

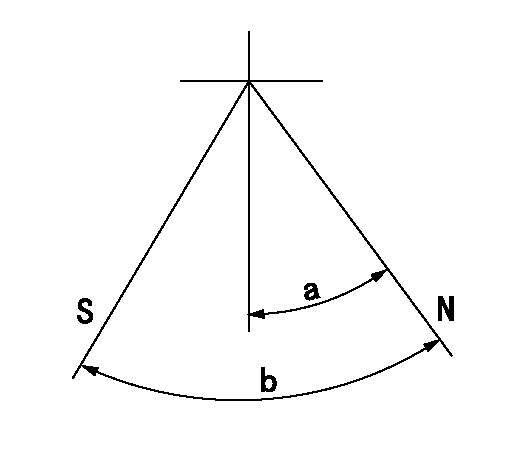

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=1.5deg+-5deg b=12deg+-5deg

----------

----------

a=1.5deg+-5deg b=12deg+-5deg

0000000901

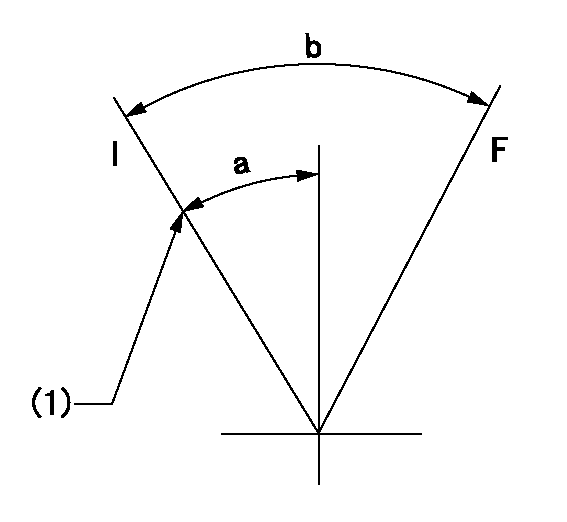

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Attach the return spring to the upper hole and adjust.

----------

----------

a=30deg+-5deg b=30deg+-3deg

----------

----------

a=30deg+-5deg b=30deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=32deg+-5deg b=64deg+-5deg

----------

----------

a=32deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(70deg)

----------

aa=11deg

----------

a=(70deg)

Information:

In this service manual, the Mitsubishi Diesel Engine (standard model for land use) specifications, maintenance standards and adjustment procedure as well as service procedures such as disassembly, inspection, repair and reassembly are arranged in groups for quick reference. There are separate manuals for the fuel injection pump, governor and turbocharger.A short summary of each group is given in the General Contents, and there is also a table of contents at the beginning of each group.Regarding engine operation and periodical maintenance, refer to the Operation & Maintenance Manual. For component parts and ordering of service parts, refer to the Parts Catalog. Structure and function of the engine are described in various training manuals.Methods of Indication

(1) Parts shown in illustrations and described in text are numbered to correspond with the sequence of disassembly.(2) Inspections to be conducted during disassembly are indicated in a box

in disassembled views.(3) Maintenance standards for inspection and repair are described in text where they are relevant, are also listed in Group 1 in the General Contents.(4) The sequence in which parts are to be assembled is summarized below each assembled view. Such as:

(5) The following marks are used in this manual to emphasize important safety cautions.

Indicates a highly hazardous situation which, if not avoided, can result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, can result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, can result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, can result in property damage. Note: Indicates important information or information which is useful for engine operation or maintenance.(6) Tightening torque under wet conditions is indicated as, "[Wet]". When so indicated, apply engine oil to the threaded portion of the fastener. Unless indicated as such, the tightening torque is to be assumed in the dry condition.Terms Used in This Manual

Nominal value - Indicates the standard dimension of a part to be measured.Standard - Indicates the dimension of a part, the clearance between parts, or the standard performance. Since the value is indicated in a range needed for inspection, it is different from the design value.Limit - A part must be repaired or replaced with a new part when it reaches the limit value.Abbreviations, Standard, Etc.

* BTDC = Before Top Dead Center* ATDC = After Top Dead Center* BBDC = Before Bottom Dead Center* ABDC = After Bottom Dead Center* TIR = Total Indicated Reading* API = American Petroleum Institute* ASTM = American Society for Testing and Materials* JIS = Japanese Industrial Standards* LLC = Long Life Coolant* MIL = Military Specifications and Standards (U.S.)* MSDS = Material Safety Data Sheet* SAE = Society of Automotive Engineers (U.S.)Units of Measurement

Measurements are based on the International System of Units (SI), and their converted metric values are indicated in parentheses ( ). For metric conversion, the following rates are used.* Pressure: 1 MPa = 10.197 kgf/cm2* Torque: 1 N m = 0.10197 kgf m* Force: 1 N

(1) Parts shown in illustrations and described in text are numbered to correspond with the sequence of disassembly.(2) Inspections to be conducted during disassembly are indicated in a box

in disassembled views.(3) Maintenance standards for inspection and repair are described in text where they are relevant, are also listed in Group 1 in the General Contents.(4) The sequence in which parts are to be assembled is summarized below each assembled view. Such as:

(5) The following marks are used in this manual to emphasize important safety cautions.

Indicates a highly hazardous situation which, if not avoided, can result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, can result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, can result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, can result in property damage. Note: Indicates important information or information which is useful for engine operation or maintenance.(6) Tightening torque under wet conditions is indicated as, "[Wet]". When so indicated, apply engine oil to the threaded portion of the fastener. Unless indicated as such, the tightening torque is to be assumed in the dry condition.Terms Used in This Manual

Nominal value - Indicates the standard dimension of a part to be measured.Standard - Indicates the dimension of a part, the clearance between parts, or the standard performance. Since the value is indicated in a range needed for inspection, it is different from the design value.Limit - A part must be repaired or replaced with a new part when it reaches the limit value.Abbreviations, Standard, Etc.

* BTDC = Before Top Dead Center* ATDC = After Top Dead Center* BBDC = Before Bottom Dead Center* ABDC = After Bottom Dead Center* TIR = Total Indicated Reading* API = American Petroleum Institute* ASTM = American Society for Testing and Materials* JIS = Japanese Industrial Standards* LLC = Long Life Coolant* MIL = Military Specifications and Standards (U.S.)* MSDS = Material Safety Data Sheet* SAE = Society of Automotive Engineers (U.S.)Units of Measurement

Measurements are based on the International System of Units (SI), and their converted metric values are indicated in parentheses ( ). For metric conversion, the following rates are used.* Pressure: 1 MPa = 10.197 kgf/cm2* Torque: 1 N m = 0.10197 kgf m* Force: 1 N