Information injection-pump assembly

ZEXEL

106693-6080

1066936080

ISUZU

1156027460

1156027460

Rating:

Service parts 106693-6080 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-218-1

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.1{225}

15.

NOZZLE SET

Include in #1:

106693-6080

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106693-6080

1066936080

ISUZU

1156027460

1156027460

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.7

3.67

3.73

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

11.2

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

162.2

160.2

164.2

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

41.3

41.3

Boost pressure

mmHg

310

310

Injection quantity adjustment_02

Adjusting point

E

Rack position

5.5+-0.5

Pump speed

r/min

240

240

240

Average injection quantity

mm3/st.

11.6

8.4

14.8

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

8.2

Boost pressure

kPa

10

8.7

11.3

Boost pressure

mmHg

75

65

85

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

9.3

Boost pressure

kPa

14

11.3

16.7

Boost pressure

mmHg

105

85

125

Boost compensator adjustment_03

Pump speed

r/min

500

500

500

Rack position

11.2

Boost pressure

kPa

28

28

28

Boost pressure

mmHg

210

210

210

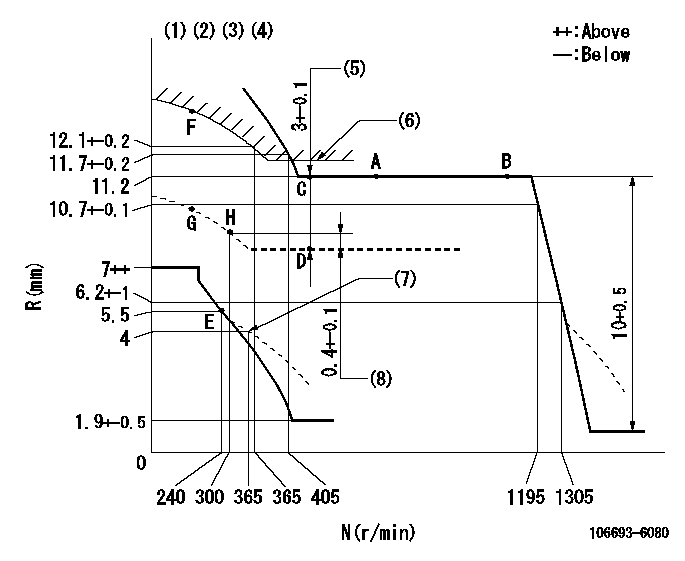

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Supplied with torque spring not set.

(5)Boost compensator stroke

(6)Excess fuel setting for starting: SXL

(7)Damper spring setting

(8)Rack difference from N = N1

----------

RT=1 TH=2.7mm SXL=11.6+-0.1mm N1=500r/min

----------

----------

RT=1 TH=2.7mm SXL=11.6+-0.1mm N1=500r/min

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(5.5)deg t1=2--sec. t2=2--sec.

----------

N1=800++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=5.5+-3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(5.5)deg t1=2--sec. t2=2--sec.

----------

N1=800++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=5.5+-3deg R01=0/4load R02=4/4load

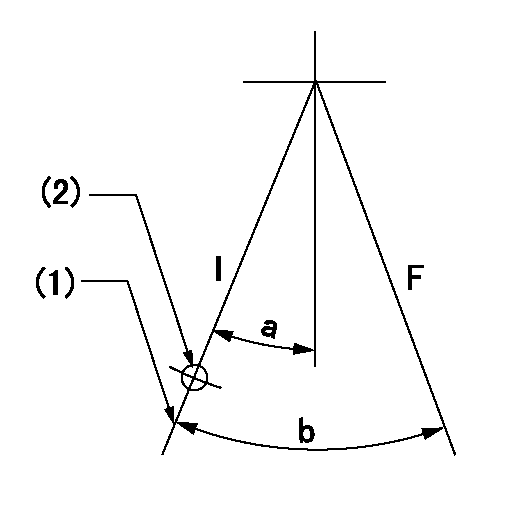

Speed control lever angle

F:Full speed

----------

----------

a=6deg+-5deg

----------

----------

a=6deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=35mm

----------

a=15deg+-5deg b=34.5deg+-3deg

----------

aa=35mm

----------

a=15deg+-5deg b=34.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(37deg)+-5deg b=73deg+-5deg

----------

----------

a=(37deg)+-5deg b=73deg+-5deg

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=700r/min Ra=11.2mm

----------

----------

N1=700r/min Ra=11.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(40deg)

----------

aa=10deg

----------

a=(40deg)

Information:

(a)When regrinding journals of the crankshaft, be sure to refinish all journals to the same dimension.(b)Finish the fillet radius to R3 mm [0.1181 in.].

Crankshaft fillet finishing dimension (2)Inspection of Oil Seal Contact Surface

Check the oil seal contact surface of the crankshaft back-end, and, if the crankshaft face has been excessively worn by the oil seal, replace the oil seal and oil sleeve with replacement parts.

Inspection of oil seal contact surface(1) Installation of oil seal sleeveTo install the oil seal sleeve, coat the inner surface of the sleeve with oil, and use the crankshaft sleeve installer for driving the sleeve into place.

Be careful not to dent or scratch the outer surface of the oil seal sleeve.

Inspection of oil seal sleeveWhen the oil seal slinger becomes worn after engine operation, remove the oil seal sleeve by following the procedure below, and replace it with a replacement oil seal assembly (oil seal and oil seal sleeve).

Inspection of oil seal contact surface(2) Removal of oil seal sleeveAt three locations on the sleeve end face, hold a chisel at a right angle to the sleeve and strike with a hammer, and remove the sleeve when it becomes loose.If this method does not allow the removal of the sleeve, hold the chisel in the axial direction and lightly tap to expand and loosen the sleeve.

Be careful not to damage the crankshaft with the chisel when removing the oil seal sleeve.

Removal of oil seal sleeveMeasurement of Crankshaft Deflection

Support the crankshaft on its front and rear journals in V-blocks, and measure the runout at the center journal with a dial gage. Compare the amount of runout with the standard. If the runout is small, correct by grinding. If the runout is large, straighten with a press.If the runout exceeds the limit significantly, replace the crankshaft.

Measurement of crankshaft deflectionRemoval of Crankshaft Gear

Use the gear puller to remove the crankshaft gear. Do not remove the crankshaft gear unless the crankshaft or gear is replaced.

Removal of crankshaft gearInstallation of Crankshaft Gear

(1) Heat the gear to a temperature of 100 to 150 °C [212 to 302 °F].(2) Install the key to the crankshaft.(3) Align the gear with key and insert the gear fully.

Installation of crankshaft gearMeasurement of Cylinder Bore

(1) Using a cylinder gage, measure the cylinder bore and cylindricity. If the limit value is exceeded even at one place, bore all cylinders and replace the pistons and piston rings with oversize pistons and piston rings. Measure at three locations each in directions A and B shown in the diagram.

Measurement of inside diameter of cylinder(2) Boring of cylinders(a) Since there are two piston oversizes (0.25 mm [0.0098 in.] and 0.50 mm [0.0197 in.] oversize) as indicated above, determine the appropriate piston size to be used based on the largest cylinder bore diameter.(b) Measure the outside diameter of the piston to be used. The piston diameter measuring points are shown in the diagram.(c) Based on the measurements of the piston outside diameter, calculate the finishing dimension to be achieved by boring.A: Piston