Information injection-pump assembly

ZEXEL

106692-9441

1066929441

KOMATSU

6151721810

6151721810

Rating:

Service parts 106692-9441 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

5.

AUTOM. ADVANCE MECHANIS

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

24.5(250)

15.

NOZZLE SET

Include in #1:

106692-9441

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106692-9441

1066929441

KOMATSU

6151721810

6151721810

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.75

3.7

3.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

109

107

111

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.7+-0.5

Pump speed

r/min

340

340

340

Average injection quantity

mm3/st.

17

15.5

18.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

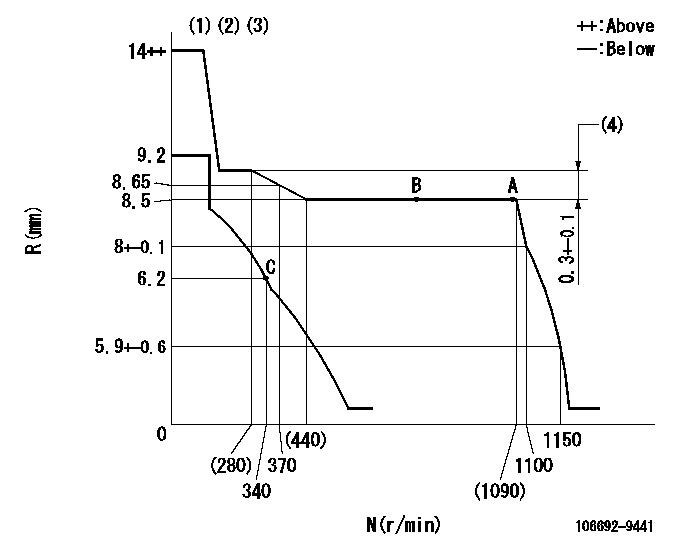

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Do not adjust boost compensator spring.

(4)Rack difference between N = N1 and N = N2

----------

K=10 N1=1050r/min N2=240r/min

----------

----------

K=10 N1=1050r/min N2=240r/min

----------

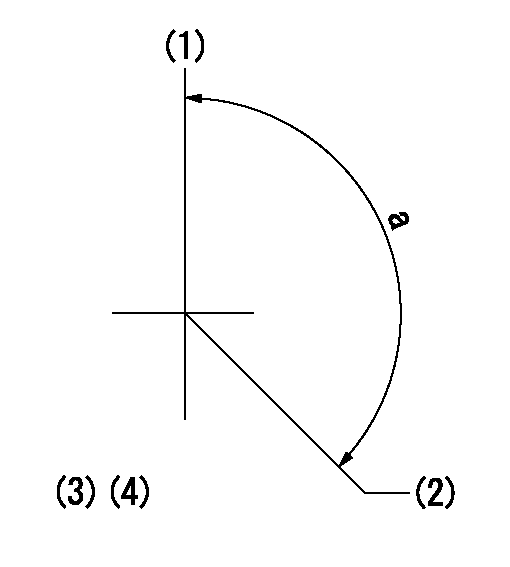

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=28deg+-5deg

----------

----------

a=9deg+-5deg b=28deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb (stamp at delivery)

----------

aa=1-0.5mm bb=0r/min

----------

a=33deg+-5deg b=70deg+-5deg

----------

aa=1-0.5mm bb=0r/min

----------

a=33deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(150deg)

----------

----------

a=(150deg)

Information:

Table 1

Revision Summary of Changes

01 Updated the effectivity. A new Diesel Exhaust Fluid (DEF) filter is now available on machines listed above. The DEF filter has an improved filter efficiency.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

The following changes are now available for the products within the listed serial numbers.Refer to Table 2 for a list of a new and former part numbers.

Table 2

Required Parts

DEF Filter DEF Manifold Group

Application New Part Number Part Name Former Part Number (1) New Part Number Part Name Former Part Number (1)

785G 584-8139 DEF Filter 453-1607 585-3956 DEF Manifold Gp 480-4090

789G, 793F, 794AC, 797F, and 994K 584-8140 DEF Filter 453-1608 585-3957 DEF Manifold Gp 480-4091

(1) The former part number listed is for reference only and may differ.Note: The new DEF manifold group part numbers listed in Table 2 will be assembled with the new filters.

Illustration 1 g06570567

DEF manifold

(1) ClampAn additional change, beyond the new DEF filter, was made to the 585-3957 DEF Manifold Gp. The clamp in the location highlighted in Illustration 2 was removed to eliminate a potential wear point.

Illustration 2 g06570636

Typical view of the DEF manifold group

(2) DEF manifold

(3) DEF filterThis change is effective for the Pump Electronic Tank Unit (PETU) serial numbers listed in Table 3.

Table 3

Pump Electronic Tank Unit (PETU) Serial Numbers

S/N:PET001414J

S/N:PET001444J-UP