Information injection-pump assembly

ZEXEL

106692-9370

1066929370

Rating:

Cross reference number

ZEXEL

106692-9370

1066929370

Zexel num

Bosch num

Firm num

Name

106692-9370

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.9

2.85

2.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

13

Pump speed

r/min

900

900

900

Each cylinder's injection qty

mm3/st.

236

231.3

240.7

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.8+-0.5

Pump speed

r/min

200

200

200

Each cylinder's injection qty

mm3/st.

32.5

28.3

36.7

Fixing the rack

*

Test data Ex:

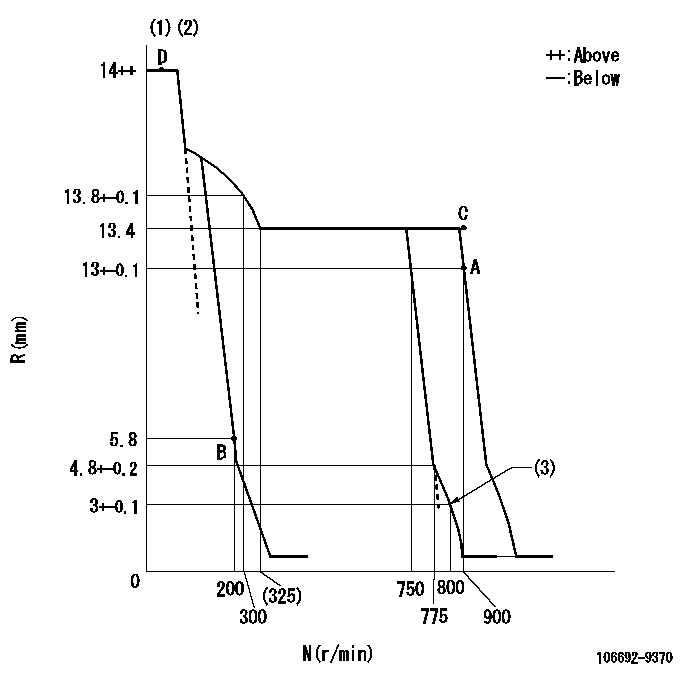

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

----------

K=5

----------

----------

K=5

----------

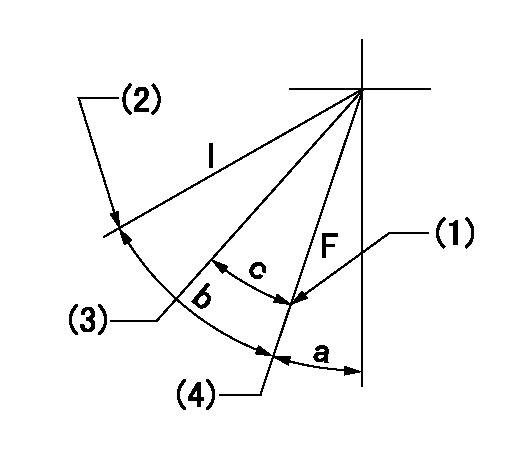

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)When pump speed set at aa

(4)Set the pump speed at bb.

----------

aa=750r/min bb=900r/min

----------

a=23deg+-5deg b=29deg+-5deg c=6deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=23deg+-5deg b=29deg+-5deg c=6deg+-5deg

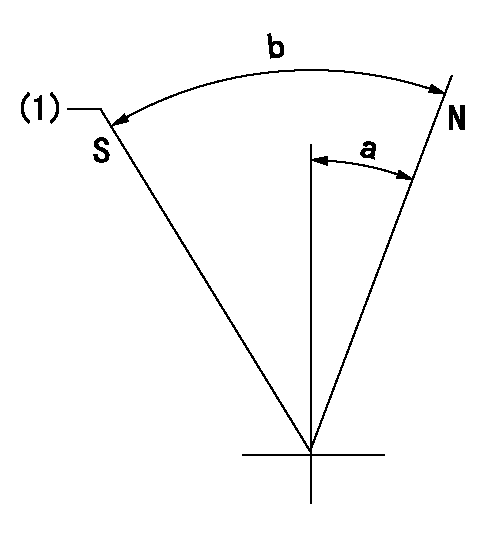

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=5.3mm bb=0r/min

----------

a=20deg+-5deg b=53deg+-5deg

----------

aa=5.3mm bb=0r/min

----------

a=20deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Hot Test Procedure

Start engine, run at low idle, and ensure minimum oil pressure of 235 kPa (34 psi) is present within 30 sec. Walk around the engine and check for leaks. Run straight diesel with Natural Gas shut off.

Check ET for Codes.

Run Break-In 1 Speed and Load for 1 min.

Break-In load and speed 2967 Nm at 1440 rpm.

Cycle Load Between Break-In 2 Load, and Break-In 1 Load, 3 times holding at each load for 30 sec.

Break-In load and speed 5933 Nm at 1800 rpm.

Remove dyno load and go to Low Idle.

Illustration 276 g06547946

Cat ET EGR system test

Run EGR verification check in ET, and ensure it Passes. Run the EGR verification check a second time if the first one fails. If itfailsagain shut the engine offand troubleshoot EGR system.

Cat ET EGR System Test.

If Aftertreatment is not installed the Exhaust Backpressure must be within pressure tolerance of 7 3 kPa (1.0 0.4 psi) at the end of Break-In 2.

Illustration 277 g06547948

Cat ET fuel system functional test

Run Fuel System verification check in ET, and ensure it Passes.Note: Checking to see, if this is needed or not

DO NOT Lug engine until the engine has a successful EGR verification check, and Engine Backpressure is acceptable (Aftertreatment installed or backpressure verified during Break-In 2).

Set engine speed to Hi Idle speed.

Lug to engine to "Full Load speed" and allow water temps to stabilize.

EJW 85° 4°C (185° 39°F).

SCAC 46° 3°C (115° 37°F).

ATAAC Out 48° 3°C (118° 37°F).

Acquire "Full Load Data".

Take screenshot from ET for some ECM parameters.

Lug engine to "Torque Check" speed and allow engine to stabilize.

Acquire "Torque Check Data".

Take screenshot from ET for some ECM parameters.

Go to "Gas Blending Speed and Load".

754 bkW at 1800 rpm.

Turn on Gas supply. Natural Gas supply pressure measured on engine should be between 100 70 kPa (15 to 10 psi).

Let engine stabilize for 1 min.

Acquire Diesel and Natural Gas fuel rates.

Take ET screenshot.

Remove engine load and stabilize at High Idle speed for 1 min.

Acquire Hi Idle Data.

Take screenshot from ET for some ECM parameters.

Set engine to Low Idle speed and stabilize for 1 min.

Acquire Low Idle Data.

Take screenshot from ET for some ECM parameters.Nominal Test Values

The following nominal value information for hot tests can be referenced in the TMI system under the following test specs:

Illustration 278 g06547949

TMI Spec Summary

Illustration 279 g06547950

Full Load Point Values (2500 hp SCAC)

Illustration 280 g06547951

Full Load Point Values (2500 hp ATAAC)

Full Load Point.

Illustration 281 g06547952

Torque Check Point Values (2500 hp SCAC)

Illustration 282 g06547953

Torque Check Point Values (2500 hp ATAAC)

Torque Check Point.

Illustration 283 g06547954

Gas Blend Point Values (2500 hp SCAC)

Illustration 284 g06547955

Gas Blend Point Values (2500 hp ATAAC)

Gas Blend Point.

Start engine, run at low idle, and ensure minimum oil pressure of 235 kPa (34 psi) is present within 30 sec. Walk around the engine and check for leaks. Run straight diesel with Natural Gas shut off.

Check ET for Codes.

Run Break-In 1 Speed and Load for 1 min.

Break-In load and speed 2967 Nm at 1440 rpm.

Cycle Load Between Break-In 2 Load, and Break-In 1 Load, 3 times holding at each load for 30 sec.

Break-In load and speed 5933 Nm at 1800 rpm.

Remove dyno load and go to Low Idle.

Illustration 276 g06547946

Cat ET EGR system test

Run EGR verification check in ET, and ensure it Passes. Run the EGR verification check a second time if the first one fails. If itfailsagain shut the engine offand troubleshoot EGR system.

Cat ET EGR System Test.

If Aftertreatment is not installed the Exhaust Backpressure must be within pressure tolerance of 7 3 kPa (1.0 0.4 psi) at the end of Break-In 2.

Illustration 277 g06547948

Cat ET fuel system functional test

Run Fuel System verification check in ET, and ensure it Passes.Note: Checking to see, if this is needed or not

DO NOT Lug engine until the engine has a successful EGR verification check, and Engine Backpressure is acceptable (Aftertreatment installed or backpressure verified during Break-In 2).

Set engine speed to Hi Idle speed.

Lug to engine to "Full Load speed" and allow water temps to stabilize.

EJW 85° 4°C (185° 39°F).

SCAC 46° 3°C (115° 37°F).

ATAAC Out 48° 3°C (118° 37°F).

Acquire "Full Load Data".

Take screenshot from ET for some ECM parameters.

Lug engine to "Torque Check" speed and allow engine to stabilize.

Acquire "Torque Check Data".

Take screenshot from ET for some ECM parameters.

Go to "Gas Blending Speed and Load".

754 bkW at 1800 rpm.

Turn on Gas supply. Natural Gas supply pressure measured on engine should be between 100 70 kPa (15 to 10 psi).

Let engine stabilize for 1 min.

Acquire Diesel and Natural Gas fuel rates.

Take ET screenshot.

Remove engine load and stabilize at High Idle speed for 1 min.

Acquire Hi Idle Data.

Take screenshot from ET for some ECM parameters.

Set engine to Low Idle speed and stabilize for 1 min.

Acquire Low Idle Data.

Take screenshot from ET for some ECM parameters.Nominal Test Values

The following nominal value information for hot tests can be referenced in the TMI system under the following test specs:

Illustration 278 g06547949

TMI Spec Summary

Illustration 279 g06547950

Full Load Point Values (2500 hp SCAC)

Illustration 280 g06547951

Full Load Point Values (2500 hp ATAAC)

Full Load Point.

Illustration 281 g06547952

Torque Check Point Values (2500 hp SCAC)

Illustration 282 g06547953

Torque Check Point Values (2500 hp ATAAC)

Torque Check Point.

Illustration 283 g06547954

Gas Blend Point Values (2500 hp SCAC)

Illustration 284 g06547955

Gas Blend Point Values (2500 hp ATAAC)

Gas Blend Point.

Have questions with 106692-9370?

Group cross 106692-9370 ZEXEL

Komatsu

Komatsu

Komatsu

Yanmar

Yanmar

Yanmar

Yanmar

Komatsu

Komatsu

Komatsu

106692-9370

INJECTION-PUMP ASSEMBLY