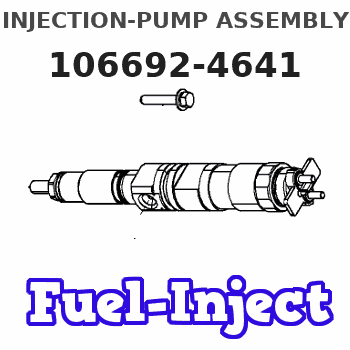

Information injection-pump assembly

ZEXEL

106692-4641

1066924641

Rating:

Cross reference number

Zexel num

Bosch num

Firm num

Name

106692-4641

INJECTION-PUMP ASSEMBLY

Information:

Do not use the same vacuum sampling pump for extracting oil samples that is used for extracting coolant samples.A small residue of either type sample may remain in the pump and may cause a false positive analysis for the sample being taken.Always use a separate pump for oil sampling and a separate pump for coolant sampling.Failure to do so may cause a false analysis which could lead to customer and dealer concerns.

Oil Sampling Interval

Take the oil samples as close as possible to the standard intervals. In order to receive the full value from S O S oil analysis, establish a consistent trend of data. In order to establish a pertinent history of data, perform consistent oil samplings that are evenly spaced.Recommended interval for engine oil samples is given in Table 2. A 250 hour sampling interval can provide a timely indication of oil contamination and oil degradation.Measure and record engine oil consumption in order to allow accurate oil analysis. Oil additions during the sampling interval dilute wear metals and other contaminants.

Table 2

S O S Oil Sampling Interval for Engine crankcase

Recommended Interval (1)(2) Oil Type

Every 250 Service Hours Cat DEO

Cat DEO-ULS

(1) Severe applications may require a more frequent oil sampling interval.

(2) Under certain conditions, the Cat dealer or the Operation and Maintenance Manual may allow a longer interval between oil samplings.Note: Refer to the Operation and Maintenance Manual for your engine for recommended oil drain intervals.Consult your Cat dealer for complete information and assistance in order to establish an S O S Services program for your engine.More Frequent S O S Sampling Improves Life Cycle Management

Traditionally, the suggested S O S sampling intervals for diesel engines have been at 250 hours. However in severe applications, more frequent oil sampling is recommended. Severe service for lubricated compartments occurs at high loads, in high temperatures, and in dusty conditions. If any of these conditions or other severe service indicators exist, sample the engine oil at 125 hour intervals. These additional samples will increase the chance of detecting a potential failure.Determining Optimum Oil Change Intervals

Sampling the engine oil at every 125 hours provides information for oil condition and for oil performance. This information is used to determine the optimum usable life of a particular oil. Also, more points of data will allow closer monitoring of component wear rates. Close monitoring also allows you to obtain the maximum use of the oil. For detailed information on optimizing oil change intervals, consult your Cat dealer.This Special Publication does not address recommended oil drain intervals. Refer to your engine Operation and Maintenance Manual, and consult your Cat dealer for additional guidance, including but not limited to guidance on establishing optimized and/or acceptable oil drain intervals.Note: The use of Cat S O S Services oil analysis helps environmental sustainability as the best way to optimize oil life. S O S Services will help engines reach expected life. Consult your Cat dealer regarding the testing required to establish a safe, optimized oil drain interval.Standard oil drain intervals as published

Have questions with 106692-4641?

Group cross 106692-4641 ZEXEL

Komatsu

Komatsu

106692-4641

INJECTION-PUMP ASSEMBLY