Information injection-pump assembly

BOSCH

9 400 617 810

9400617810

ZEXEL

106692-1230

1066921230

ISUZU

1156021310

1156021310

Rating:

Service parts 106692-1230 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106692-1230

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 810

9400617810

ZEXEL

106692-1230

1066921230

ISUZU

1156021310

1156021310

Zexel num

Bosch num

Firm num

Name

106692-1230

9 400 617 810

1156021310 ISUZU

INJECTION-PUMP ASSEMBLY

6RB1T * K 14CA PE6P,6PD PE

6RB1T * K 14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

127.5

125.5

129.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.6

Pump speed

r/min

725

725

725

Average injection quantity

mm3/st.

176

172.2

179.8

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

6.8+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

24

20.8

27.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

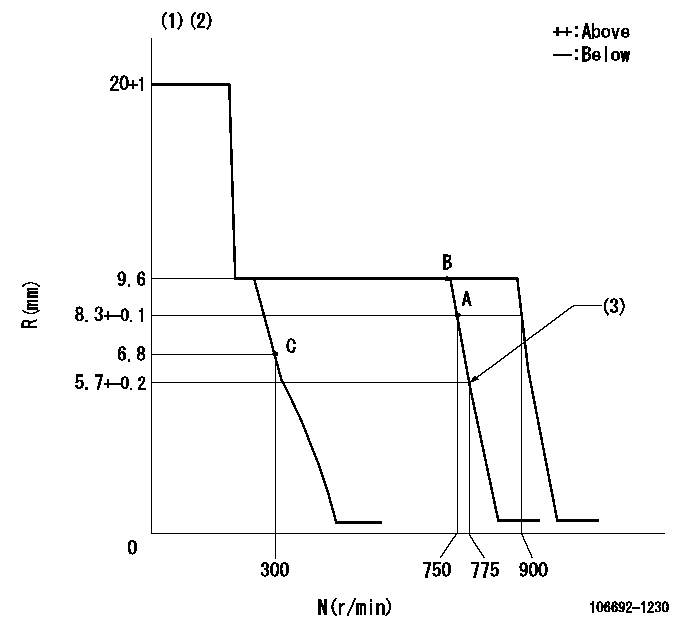

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Idle sub spring setting: L1.

----------

K=8 L1=5.7-0.5mm

----------

----------

K=8 L1=5.7-0.5mm

----------

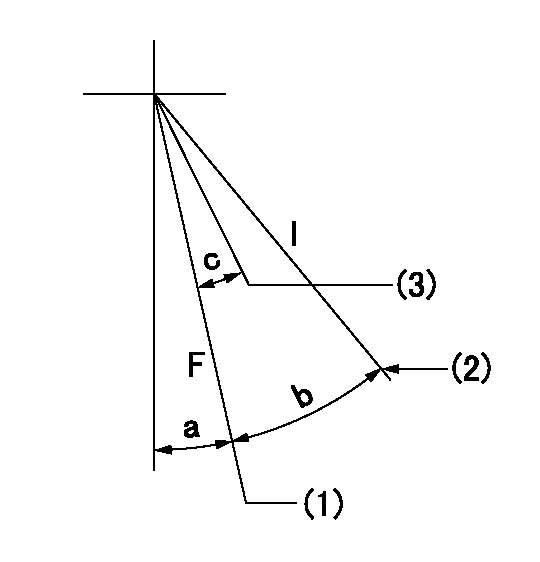

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Stopper bolt setting

(3)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=6deg+-5deg b=15deg+-5deg c=4deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=6deg+-5deg b=15deg+-5deg c=4deg+-5deg

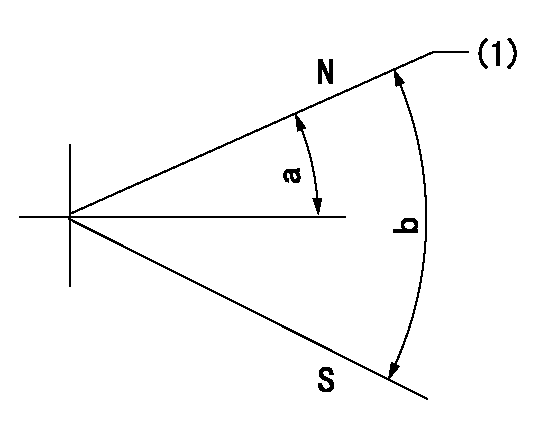

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=10deg+-5deg b=53deg+-5deg

----------

----------

a=10deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '0' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Moisture Content

Problems with fuel filters can occur at any time. The cause of the problem can be water in the fuel or moisture in the fuel. At low temperatures, moisture causes special problems. There are three types of moisture in fuel: dissolved moisture (moisture in solution), free and dispersed moisture in the fuel and free and settled at the bottom of the tank.Most diesel fuels have some dissolved moisture. Just as the moisture in air, the fuel can only contain a specific maximum amount of moisture at any one temperature. The amount of moisture decreases as the temperature is lowered. For example, a fuel could contain 100 ppm(100 mg/kg or 0.010 percent) of water in solution at 18°C (65°F). This same fuel can possibly hold only 30 ppm(30 ppm or 0.003 percent) at 4°C (40°F).After the fuel has absorbed the maximum amount of water, the additional water will be free and dispersed. Free and dispersed moisture is fine droplets of water that is suspended in the fuel. Since the water is heavier than the fuel, the water will slowly become free and settled at the bottom of the tank. In the above example, when the fuel temperature was lowered from 18°C (65°F) to 4°C (40°F), 70 ppm(mg/kg) of water became free and dispersed in the fuel.The small drops of water cause a cloudy appearance in the fuel. If the change in temperature is slow, the small drops of water can settle to the bottom of the tank. When the fuel temperature is lowered rapidly to freezing temperature, the moisture that comes out-of-solution changes to very fine particles of ice instead of small drops of water.The particles of ice are lighter than the fuel, and the particles of ice will not settle to the bottom of the tank. When this type of moisture is mixed in the fuel, this moisture will fill the fuel filters. The ice crystals will plug the fuel filters in the same way as wax plugs the fuel filters.If a filter is plugged and fuel flow is stopped, perform the following procedure to determine the cause:

Remove the fuel filters.

Cut the fuel filters open.

Inspect the fuel filter before the filter warms. This inspection will show that the filter is filled with particles of either ice or wax.The moisture which is free and settled at the bottom of the tank can become mixed with the fuel. The force of any pumping action will mix the moisture with the fuel whenever fuel is transferred. This moisture then becomes free and dispersed water. This moisture can cause ice in the filters. This moisture can cause other problems with filters at any temperature. Generally, the same force that mixes the water into the fuel will also mix dirt and rust from the bottom of the tank with the water. The result is a dirty mixture of fuel and water which can also fill the filters and stop fuel flow.Specific Gravity / API Gravity

The specific gravity of diesel fuel is the

Problems with fuel filters can occur at any time. The cause of the problem can be water in the fuel or moisture in the fuel. At low temperatures, moisture causes special problems. There are three types of moisture in fuel: dissolved moisture (moisture in solution), free and dispersed moisture in the fuel and free and settled at the bottom of the tank.Most diesel fuels have some dissolved moisture. Just as the moisture in air, the fuel can only contain a specific maximum amount of moisture at any one temperature. The amount of moisture decreases as the temperature is lowered. For example, a fuel could contain 100 ppm(100 mg/kg or 0.010 percent) of water in solution at 18°C (65°F). This same fuel can possibly hold only 30 ppm(30 ppm or 0.003 percent) at 4°C (40°F).After the fuel has absorbed the maximum amount of water, the additional water will be free and dispersed. Free and dispersed moisture is fine droplets of water that is suspended in the fuel. Since the water is heavier than the fuel, the water will slowly become free and settled at the bottom of the tank. In the above example, when the fuel temperature was lowered from 18°C (65°F) to 4°C (40°F), 70 ppm(mg/kg) of water became free and dispersed in the fuel.The small drops of water cause a cloudy appearance in the fuel. If the change in temperature is slow, the small drops of water can settle to the bottom of the tank. When the fuel temperature is lowered rapidly to freezing temperature, the moisture that comes out-of-solution changes to very fine particles of ice instead of small drops of water.The particles of ice are lighter than the fuel, and the particles of ice will not settle to the bottom of the tank. When this type of moisture is mixed in the fuel, this moisture will fill the fuel filters. The ice crystals will plug the fuel filters in the same way as wax plugs the fuel filters.If a filter is plugged and fuel flow is stopped, perform the following procedure to determine the cause:

Remove the fuel filters.

Cut the fuel filters open.

Inspect the fuel filter before the filter warms. This inspection will show that the filter is filled with particles of either ice or wax.The moisture which is free and settled at the bottom of the tank can become mixed with the fuel. The force of any pumping action will mix the moisture with the fuel whenever fuel is transferred. This moisture then becomes free and dispersed water. This moisture can cause ice in the filters. This moisture can cause other problems with filters at any temperature. Generally, the same force that mixes the water into the fuel will also mix dirt and rust from the bottom of the tank with the water. The result is a dirty mixture of fuel and water which can also fill the filters and stop fuel flow.Specific Gravity / API Gravity

The specific gravity of diesel fuel is the

Have questions with 106692-1230?

Group cross 106692-1230 ZEXEL

Isuzu

106692-1230

9 400 617 810

1156021310

INJECTION-PUMP ASSEMBLY

6RB1T

6RB1T