Information injection-pump assembly

BOSCH

9 400 610 255

9400610255

ZEXEL

106692-1220

1066921220

ISUZU

1156020580

1156020580

Rating:

Service parts 106692-1220 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-041-2

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106692-1220

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 610 255

9400610255

ZEXEL

106692-1220

1066921220

ISUZU

1156020580

1156020580

Zexel num

Bosch num

Firm num

Name

106692-1220

9 400 610 255

1156020580 ISUZU

INJECTION-PUMP ASSEMBLY

6RB1T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6RB1T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

174.5

172.5

176.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.2+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

11.4

8.2

14.6

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.8+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

160

160

Fixing the lever

*

Rack limit

*

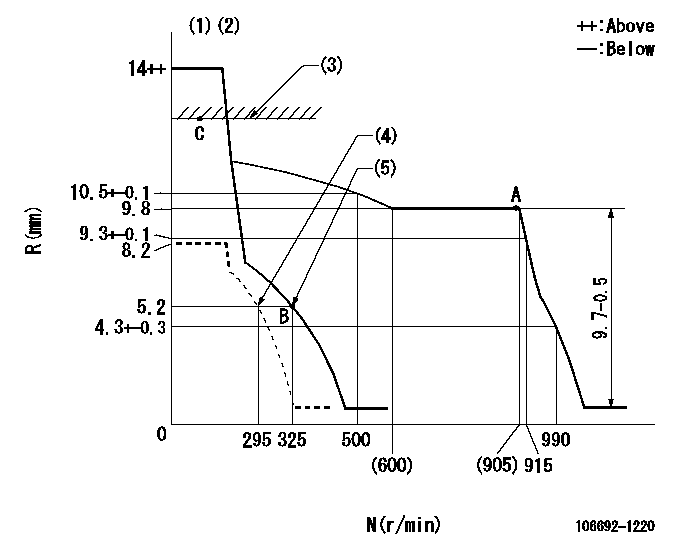

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=9

----------

----------

K=9

----------

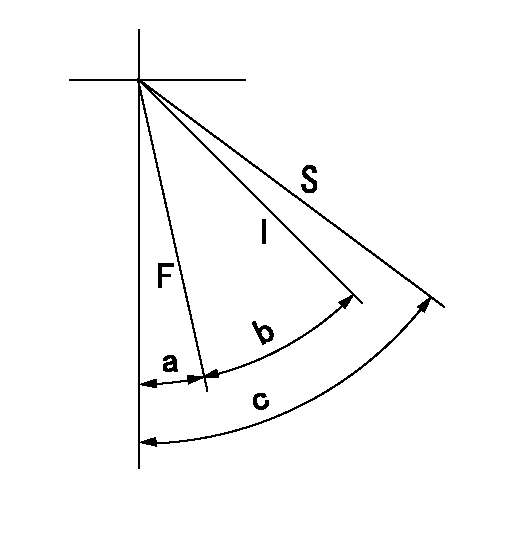

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=0deg+-5deg b=23deg+-5deg c=32deg+-3deg

----------

----------

a=0deg+-5deg b=23deg+-5deg c=32deg+-3deg

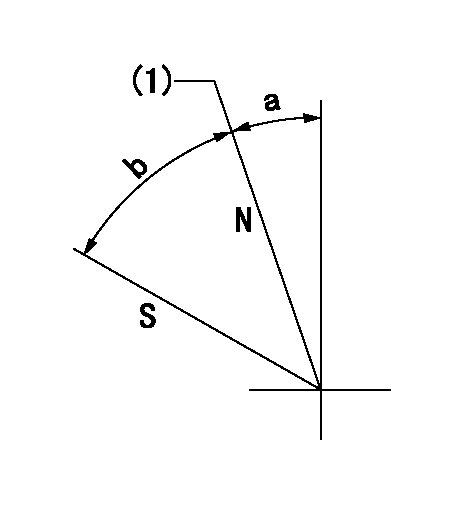

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=22deg+-5deg b=46deg+-5deg

----------

----------

a=22deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '0' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Lower - To drop to a reduced energy position. To reduce the level of material in a container. To cause to descend.

Loosen - To make less tight. To set free. To release.

Measure - To determine the dimension, area, volume, or other quantifiable property of an object. A desired quantity of something.

Open - To unseal or get access to.

Operation and Maintenance Manual - Refer to a procedure in the Operation and Maintenance Manual.

Position - To locate to the desired or intended location.

Relieve - To eliminate the pressure or force on a part or system to reduce a pressure, load, or weight on a device.

Remove - To take off.

Replace - To put back in place.

Rotate - Counter Clockwise - To turn on an axis. To alternate position or orientation, for the purpose of achieving even wear.

Tighten - To make nearer, to fully stretch, without slack, or to apply tension or torque.Machine Preparation

Illustration 2 g06181614

Illustration 3 g06181622

Illustration 4 g06303840

Refer to the Operation and Maintenance Manual , Machine Preparation for Troubleshooting for the machine that is being worked on in order to release system pressure.

Illustration 5 g06181692Location of Rework

Illustration 6 g06287569Rework Procedure

Illustration 7 g06287850

Illustration 8 g06304138

Illustration 9 g06304142

Loosen - To make less tight. To set free. To release.

Measure - To determine the dimension, area, volume, or other quantifiable property of an object. A desired quantity of something.

Open - To unseal or get access to.

Operation and Maintenance Manual - Refer to a procedure in the Operation and Maintenance Manual.

Position - To locate to the desired or intended location.

Relieve - To eliminate the pressure or force on a part or system to reduce a pressure, load, or weight on a device.

Remove - To take off.

Replace - To put back in place.

Rotate - Counter Clockwise - To turn on an axis. To alternate position or orientation, for the purpose of achieving even wear.

Tighten - To make nearer, to fully stretch, without slack, or to apply tension or torque.Machine Preparation

Illustration 2 g06181614

Illustration 3 g06181622

Illustration 4 g06303840

Refer to the Operation and Maintenance Manual , Machine Preparation for Troubleshooting for the machine that is being worked on in order to release system pressure.

Illustration 5 g06181692Location of Rework

Illustration 6 g06287569Rework Procedure

Illustration 7 g06287850

Illustration 8 g06304138

Illustration 9 g06304142

Have questions with 106692-1220?

Group cross 106692-1220 ZEXEL

Isuzu

106692-1220

9 400 610 255

1156020580

INJECTION-PUMP ASSEMBLY

6RB1T

6RB1T