Information injection-pump assembly

BOSCH

9 400 617 809

9400617809

ZEXEL

106692-1210

1066921210

ISUZU

1156021030

1156021030

Rating:

Service parts 106692-1210 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106692-1210

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 809

9400617809

ZEXEL

106692-1210

1066921210

ISUZU

1156021030

1156021030

Zexel num

Bosch num

Firm num

Name

106692-1210

9 400 617 809

1156021030 ISUZU

INJECTION-PUMP ASSEMBLY

6RB1T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6RB1T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

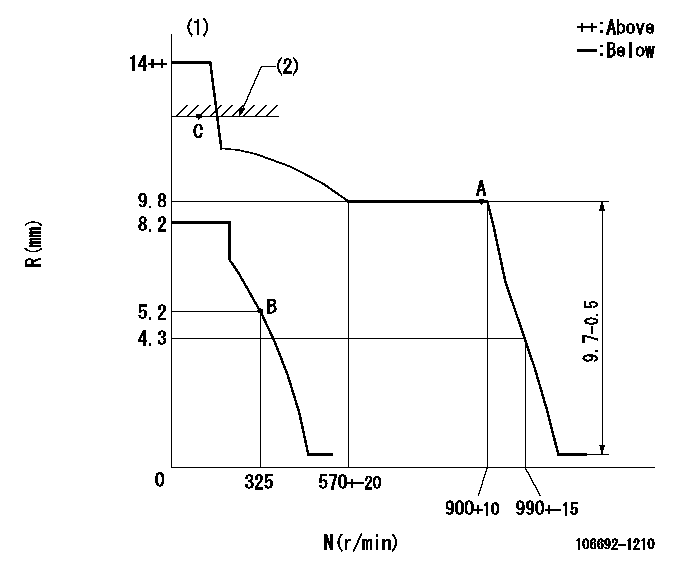

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

174.5

172.5

176.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.2+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

11.4

8.2

14.6

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

160

160

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

----------

K=6

----------

----------

K=6

----------

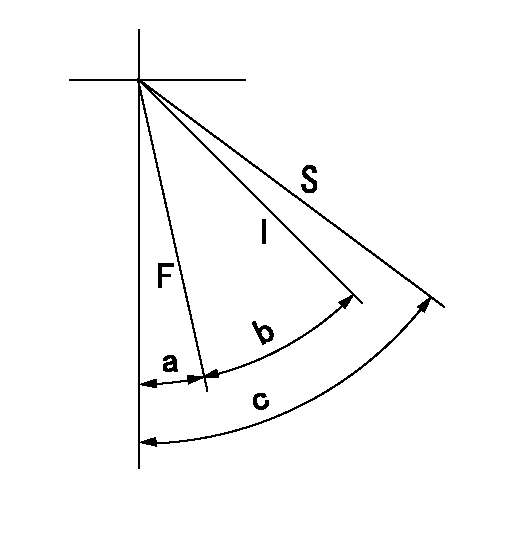

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=0deg+-5deg b=25deg+-5deg c=32deg+-3deg

----------

----------

a=0deg+-5deg b=25deg+-5deg c=32deg+-3deg

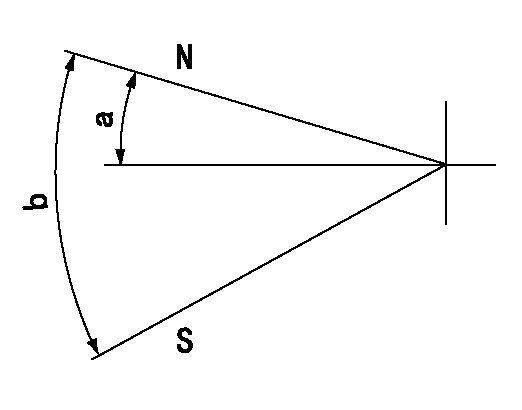

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=12deg+-5deg b=46deg+-5deg

----------

----------

a=12deg+-5deg b=46deg+-5deg

Information:

Removal Procedure for the Fuel Injection Pump

Table 1

Required Tools

Tool Part Number and Part Description Qty

A 267-2647 Stop Plug 1

B 9S-4180 Plug 1

Remove the air compressor. Refer to Disassembly and Assembly, "Air Compressor - Remove and Install".Note: Cleanliness is a critical factor. Before you begin the removal procedure, the exterior of the components should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism.

Contact with high pressure fuel may cause personal injury or death. Wait 60 seconds after the engine has stopped to allow fuel pressure to purge before any service or repair is performed on the engine fuel lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and mandates.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Contact with high pressure fuel may cause fluid penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

Illustration 11 g01352511

Remove tube assembly (1), tube assembly (3), and tube assembly (4) .

Disconnect tube assembly (5) and tube assembly (6). Remove bolts (2) .

Remove Tooling (B) and install Tooling (A) .

Illustration 12 g01352571

Disconnect harness assemblies (8). Remove nuts (9) and the support assembly.

Remove bolts (10). Slide fuel injection pump (11) out of the front housing and disconnect hose assembly (7). Remove fuel injection pump (11) by pulling straight out of the front housing.Installation Procedure for the Fuel Injection Pump

Table 2

Required Tools

Tool Part Number and Part Description Qty

A 267-2647 Stop Plug 1

B 9S-4180 Plug 1

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

Illustration 13 g01352571

Note: Ensure that Tooling (A) is installed prior to installation of the fuel injection pump.

Align fuel injection pump (11) in the correct orientation relative to the front housing. Connect hose assembly (7) .

Install fuel injection pump (11). Move fuel injection pump (11) straight into the front housing in order to properly engage the gear. Install bolts (10) .

Install the support assembly and nuts (9). Connect harness assemblies (8) .

Illustration 14 g01352511

Remove Tooling (A) and install Tooling (B). Tighten Tooling (B) to a torque of 4.5 0.5 N m (40.0 4.0 lb in).

Install bolts (2). Connect tube assembly (6) and tube assembly (5)

Table 1

Required Tools

Tool Part Number and Part Description Qty

A 267-2647 Stop Plug 1

B 9S-4180 Plug 1

Remove the air compressor. Refer to Disassembly and Assembly, "Air Compressor - Remove and Install".Note: Cleanliness is a critical factor. Before you begin the removal procedure, the exterior of the components should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism.

Contact with high pressure fuel may cause personal injury or death. Wait 60 seconds after the engine has stopped to allow fuel pressure to purge before any service or repair is performed on the engine fuel lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and mandates.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Contact with high pressure fuel may cause fluid penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

Illustration 11 g01352511

Remove tube assembly (1), tube assembly (3), and tube assembly (4) .

Disconnect tube assembly (5) and tube assembly (6). Remove bolts (2) .

Remove Tooling (B) and install Tooling (A) .

Illustration 12 g01352571

Disconnect harness assemblies (8). Remove nuts (9) and the support assembly.

Remove bolts (10). Slide fuel injection pump (11) out of the front housing and disconnect hose assembly (7). Remove fuel injection pump (11) by pulling straight out of the front housing.Installation Procedure for the Fuel Injection Pump

Table 2

Required Tools

Tool Part Number and Part Description Qty

A 267-2647 Stop Plug 1

B 9S-4180 Plug 1

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

Illustration 13 g01352571

Note: Ensure that Tooling (A) is installed prior to installation of the fuel injection pump.

Align fuel injection pump (11) in the correct orientation relative to the front housing. Connect hose assembly (7) .

Install fuel injection pump (11). Move fuel injection pump (11) straight into the front housing in order to properly engage the gear. Install bolts (10) .

Install the support assembly and nuts (9). Connect harness assemblies (8) .

Illustration 14 g01352511

Remove Tooling (A) and install Tooling (B). Tighten Tooling (B) to a torque of 4.5 0.5 N m (40.0 4.0 lb in).

Install bolts (2). Connect tube assembly (6) and tube assembly (5)

Have questions with 106692-1210?

Group cross 106692-1210 ZEXEL

Isuzu

106692-1210

9 400 617 809

1156021030

INJECTION-PUMP ASSEMBLY

6RB1T

6RB1T