Information injection-pump assembly

BOSCH

9 400 610 254

9400610254

ZEXEL

106692-1050

1066921050

ISUZU

1156009361

1156009361

Rating:

Service parts 106692-1050 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

8.

_

9.

_

11.

Nozzle and Holder

1-15300-041-2

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106692-1050

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 610 254

9400610254

ZEXEL

106692-1050

1066921050

ISUZU

1156009361

1156009361

Zexel num

Bosch num

Firm num

Name

106692-1050

9 400 610 254

1156009361 ISUZU

INJECTION-PUMP ASSEMBLY

E120 * K 14CA PE6P,6PD PE

E120 * K 14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

6.4

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

85.8

83.8

87.8

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

95.3

93.3

97.3

Max. variation between cylinders

%

0

-10

10

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

5+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

14.9

11.7

18.1

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

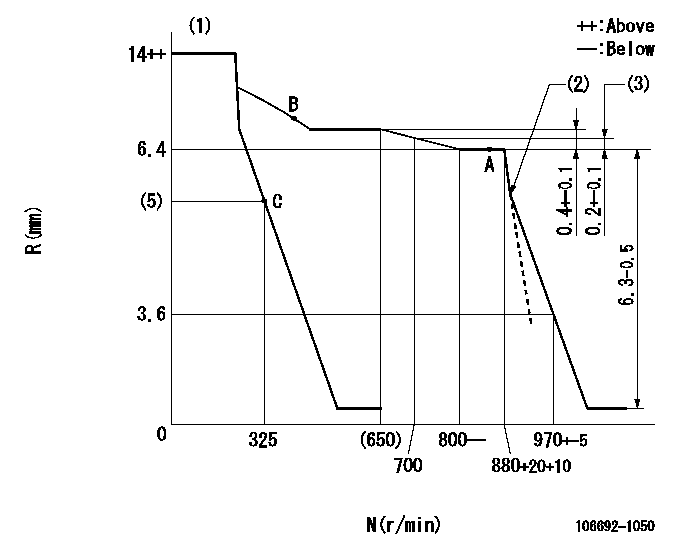

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Idle sub spring setting: L1.

(3)Rack difference between N = N1 and N = N2

----------

K=18 L1=6-0.3mm N1=850r/min N2=700r/min

----------

----------

K=18 L1=6-0.3mm N1=850r/min N2=700r/min

----------

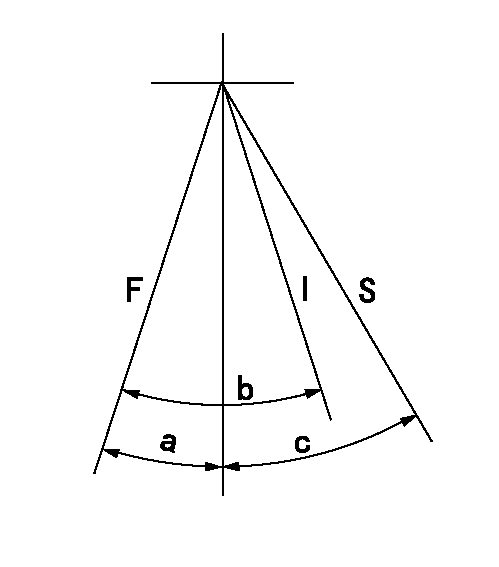

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=4deg+-5deg b=27deg+-5deg c=32deg+-3deg

----------

----------

a=4deg+-5deg b=27deg+-5deg c=32deg+-3deg

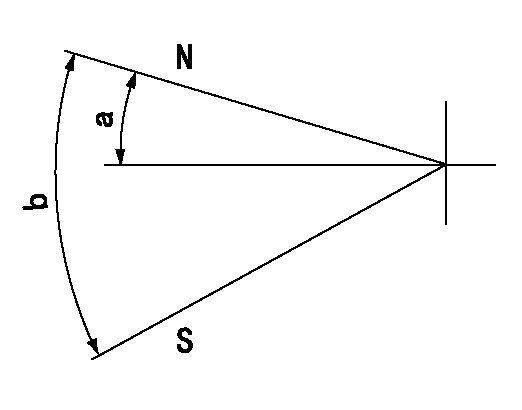

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=3deg+-5deg b=46deg+-5deg

----------

----------

a=3deg+-5deg b=46deg+-5deg

Information:

Introduction

The Environmental Protection Agency (EPA) has mandated that a DEF quality sensor must be installed on certain engines built after 2016. This new DEF quality sensor is integrated into the DEF header inside the DEF tank. The new style DEF header utilizes CAN C communication, so the wiring to the DEF header has been slightly modified on product going forward. However, the Dosing Control Unit (DCU) remains compatible to both setups with the latest engine software. ( 507-7605 Engine Software (24V DCU) or 507-7546 Engine Software (12V DCU)). As part of the DEF quality sensor implementation, a new configuration parameter setting is used on the engine Electronic Control Module (ECM) in Cat ET to identify whether a DEF quality sensor is"installed" or "not installed". Below are some different diagnostic codes for incompatible hardware and configuration setting as well as different service scenarios that may be encountered with this change and how to resolve any issues in these particular service scenarios. In addition to this Special Instruction, there is a video detailing these changes posted on Cat Channel 1.Diagnostic Codes When Parts/Settings Are Not Compatible

DEF quality header not installed but configuration set to "installed".

Table 1

J1939 Code and Description CDL Code and Description

1235-9

J1939 Network #3 : Abnormal Update Rate 5856-9

J1939 Network #3 : Abnormal Update Rate DEF quality header installed but configuration set to not installed.

Table 2

J1939 Code and Description CDL Code and Description

1761-3

Aftertreatment 1 Diesel Exhaust Fluid Tank Level : Voltage Above Normal 3130-3

Aftertreatment #1 SCR Catalyst Reagent Tank #1 Level Sensor : Voltage Above Normal

3031-3

Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature : Voltage Above Normal 3134-3

Aftertreatment #1 SCR Catalyst Reagent Tank #1 Temperature Sensor : Voltage Above Normal DEF Quality Sensor Service Scenarios

Replacement Industrial Engine (2016 and earlier builds)

Replace with new engine (old engine no longer serviceable). Update to DEF quality sensor by installing a new DEF header, wiring harness, and DCU software and changing DEF quality sensor configuration status to "installed" in Cat ET.Replacement Machine Engine (2016 and Earlier Builds)

Replace with older service replacement Engine Arrangement Complete (EAC) engine (no other changes needed, confirm that DEF quality sensor configuration is set to "not installed" in CAT ET).

If dealer orders new EAC, update to DEF quality sensor is required (below scenario).Replacement Engine (2017and Future Builds)

Replace with latest EAC engine.Install DEF Quality Sensor on 2016 or Earlier Builds

Requires DCU software update, Pump, Electronic, and Tank Unit (PETU) wiring harness update, change DEF quality sensor configuration status to"installed".Replace DCU

No effect - new DCU hardware and software is compatible to both DEF headers.Replace Engine ECM

No effect when using ECM replacement file.

If engine ECM is replaced without the ECM replacement file, the DEF quality sensor configuration setting will default to "not installed" and may need to be updated if machine utilizes DEF quality sensor (requires Factory Passwords to change).Replace Wiring Harness

No effect - both new and old harness part numbers are available. Order same part number that is removed.

The Environmental Protection Agency (EPA) has mandated that a DEF quality sensor must be installed on certain engines built after 2016. This new DEF quality sensor is integrated into the DEF header inside the DEF tank. The new style DEF header utilizes CAN C communication, so the wiring to the DEF header has been slightly modified on product going forward. However, the Dosing Control Unit (DCU) remains compatible to both setups with the latest engine software. ( 507-7605 Engine Software (24V DCU) or 507-7546 Engine Software (12V DCU)). As part of the DEF quality sensor implementation, a new configuration parameter setting is used on the engine Electronic Control Module (ECM) in Cat ET to identify whether a DEF quality sensor is"installed" or "not installed". Below are some different diagnostic codes for incompatible hardware and configuration setting as well as different service scenarios that may be encountered with this change and how to resolve any issues in these particular service scenarios. In addition to this Special Instruction, there is a video detailing these changes posted on Cat Channel 1.Diagnostic Codes When Parts/Settings Are Not Compatible

DEF quality header not installed but configuration set to "installed".

Table 1

J1939 Code and Description CDL Code and Description

1235-9

J1939 Network #3 : Abnormal Update Rate 5856-9

J1939 Network #3 : Abnormal Update Rate DEF quality header installed but configuration set to not installed.

Table 2

J1939 Code and Description CDL Code and Description

1761-3

Aftertreatment 1 Diesel Exhaust Fluid Tank Level : Voltage Above Normal 3130-3

Aftertreatment #1 SCR Catalyst Reagent Tank #1 Level Sensor : Voltage Above Normal

3031-3

Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature : Voltage Above Normal 3134-3

Aftertreatment #1 SCR Catalyst Reagent Tank #1 Temperature Sensor : Voltage Above Normal DEF Quality Sensor Service Scenarios

Replacement Industrial Engine (2016 and earlier builds)

Replace with new engine (old engine no longer serviceable). Update to DEF quality sensor by installing a new DEF header, wiring harness, and DCU software and changing DEF quality sensor configuration status to "installed" in Cat ET.Replacement Machine Engine (2016 and Earlier Builds)

Replace with older service replacement Engine Arrangement Complete (EAC) engine (no other changes needed, confirm that DEF quality sensor configuration is set to "not installed" in CAT ET).

If dealer orders new EAC, update to DEF quality sensor is required (below scenario).Replacement Engine (2017and Future Builds)

Replace with latest EAC engine.Install DEF Quality Sensor on 2016 or Earlier Builds

Requires DCU software update, Pump, Electronic, and Tank Unit (PETU) wiring harness update, change DEF quality sensor configuration status to"installed".Replace DCU

No effect - new DCU hardware and software is compatible to both DEF headers.Replace Engine ECM

No effect when using ECM replacement file.

If engine ECM is replaced without the ECM replacement file, the DEF quality sensor configuration setting will default to "not installed" and may need to be updated if machine utilizes DEF quality sensor (requires Factory Passwords to change).Replace Wiring Harness

No effect - both new and old harness part numbers are available. Order same part number that is removed.

Have questions with 106692-1050?

Group cross 106692-1050 ZEXEL

Isuzu

106692-1050

9 400 610 254

1156009361

INJECTION-PUMP ASSEMBLY

E120

E120