Information injection-pump assembly

BOSCH

9 400 619 733

9400619733

ZEXEL

106691-6730

1066916730

ISUZU

1156010251

1156010251

Rating:

Service parts 106691-6730 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106691-6730

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 733

9400619733

ZEXEL

106691-6730

1066916730

ISUZU

1156010251

1156010251

Zexel num

Bosch num

Firm num

Name

106691-6730

9 400 619 733

1156010251 ISUZU

INJECTION-PUMP ASSEMBLY

E120 * K 14CA PE6P,6PD PE

E120 * K 14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

136.4

132.6

140.2

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

22.5

19.3

25.7

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Timer adjustment

Pump speed

r/min

700+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.7

0.2

1.2

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

2.7

2.2

3.2

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4.5

4

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

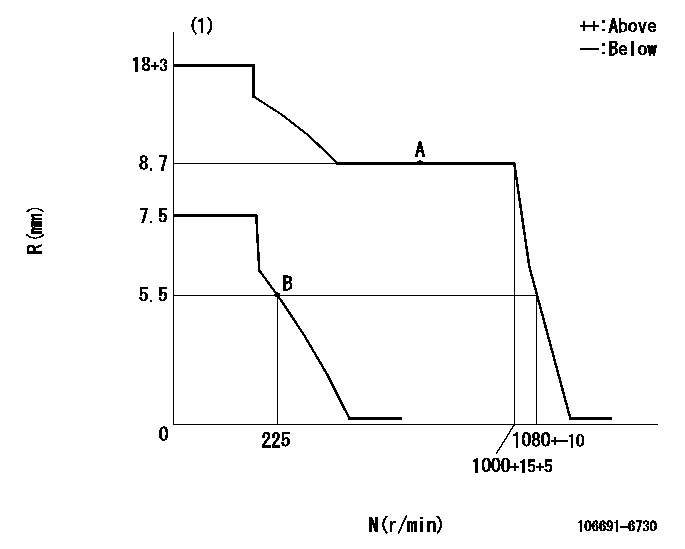

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=20

----------

----------

K=20

----------

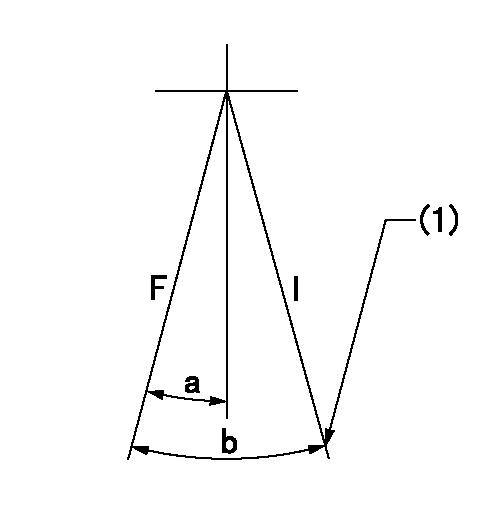

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(10deg)+-5deg b=18deg+-5deg

----------

----------

a=(10deg)+-5deg b=18deg+-5deg

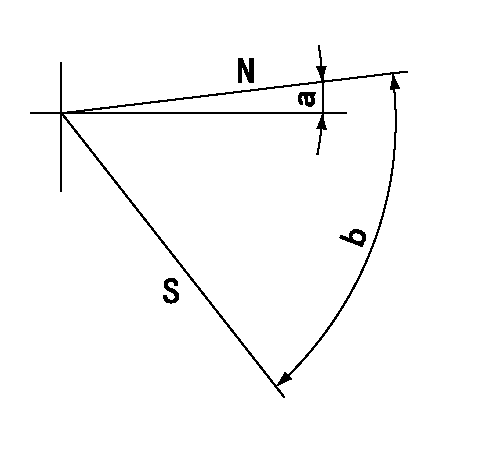

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=10deg+-5deg b=53deg+-5deg

----------

----------

a=10deg+-5deg b=53deg+-5deg

Information:

These recommendations are subject to change without notice. Consult your local Cat dealer for the most up to date recommendations.

Note: Non-Cat commercial greases are as a group second choice greases. Within this grouping of second choice greases there are tiered levels of performance.

Cat does not warrant the quality or performance of non-Cat fluids and greases.

Caterpillar provides a family of grease products that vary in performance from moderate to high performance. These greases service the entire line of Cat products in the wide variety of climates throughout the world. From this variety of Cat grease products, you can find a Cat grease that will meet or exceed the performance requirements for almost every machine that is produced by any Original Equipment Manufacturer (OEM), and for almost every machine application or equipment application.Before selecting a grease product, the performance requirements must be determined. Consult the grease recommendations in your Operation and Maintenance Manual. Also, consult your Cat dealer for a list of greases that have the performance specifications and the available container sizes.This grease chapter refers to NLGI of the grease products offered by Caterpillar. The National Lubricating Grease Institute (NLGI) classifies the greases per their consistency or hardness according to "ASTM D4950" and "SAE J310". The higher the NLGI value the more firm the grease. NLGI is an important classification for greases and it should be used along with other properties such as stability, corrosion resistance, viscosity, etc.Note: Always choose grease that meets or exceeds the recommendations that are specified by the equipment manufacturer for the application.Some work sites require the use of a single grease to fulfill the needs of all the equipment. Always choose a grease that meets or exceeds the requirements of the most demanding application. Remember that commercial products which barely meet the minimum performance requirements can be expected to produce the minimum life for the parts. It is not recommended to purchase grease products based on the lowest cost as the only consideration. Instead, use the grease that yields the lowest total operating cost. This cost should be based on an analysis that includes the improved product life, costs of parts, labor, downtime, and the cost of the amount of grease that is required.Note: Certain Cat grease products are formulated with Molybdenum disulfide (MoS2 or “Moly”). The Moly used in Cat greases is of a technical fine grade. This size meets the special requirements of some rolling element bearings, joints, and other moving components of tight clearances.Note: When the grease in a joint is changed from one type of grease to another or a grease from a different supplier is to be used, the general recommendation is to purge all of the old grease from the joint. Some greases are not chemically compatible. Consult your supplier in order to determine if the greases are compatible.If in doubt, Purge!Note: All Cat greases are “chemically” compatible with each other. Mixing of Cat greases will not result in an adverse chemical reaction. However, mixing of Cat greases

Have questions with 106691-6730?

Group cross 106691-6730 ZEXEL

Isuzu

106691-6730

9 400 619 733

1156010251

INJECTION-PUMP ASSEMBLY

E120

E120