Information injection-pump assembly

ZEXEL

106691-6571

1066916571

ISUZU

1156009524

1156009524

Rating:

Cross reference number

ZEXEL

106691-6571

1066916571

ISUZU

1156009524

1156009524

Zexel num

Bosch num

Firm num

Name

106691-6571

1156009524 ISUZU

INJECTION-PUMP ASSEMBLY

6RB1 * K

6RB1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

B

Rack position

8.9

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

133.9

131.9

135.9

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.3+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.4

15.8

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500

Advance angle

deg.

0.3

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

1

0.1

1

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.2

0.7

1.7

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

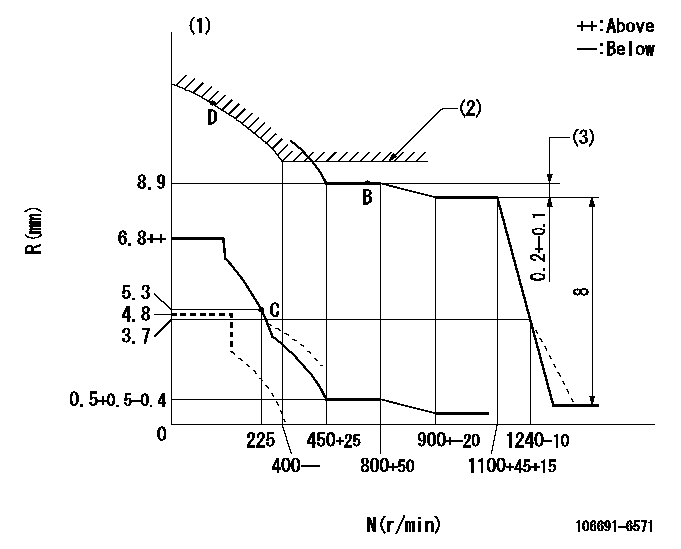

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

(3)Rack difference between N = N1 and N = N2

----------

DL=3.7-0.5mm SXL=9.2+0.2mm N1=1100r/min N2=650r/min

----------

----------

DL=3.7-0.5mm SXL=9.2+0.2mm N1=1100r/min N2=650r/min

----------

0000000901

F:Full load

I:Idle

S:Stop

(1)Rack position aa (pump speed bb r/min )

----------

aa=4.8mm bb=0r/min

----------

a=26.5deg+-5deg b=31deg+-3deg c=15deg+-5deg

----------

aa=4.8mm bb=0r/min

----------

a=26.5deg+-5deg b=31deg+-3deg c=15deg+-5deg

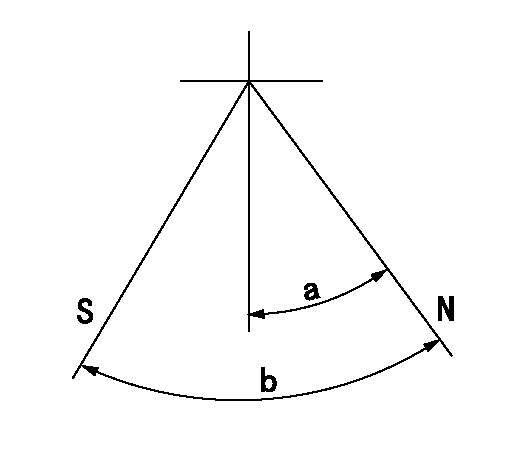

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=32deg+-5deg b=64deg+-5deg

----------

----------

a=32deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=21deg

----------

a=(70deg)

----------

aa=21deg

----------

a=(70deg)

Information:

In order to avoid potential damage to your Cat machine and/or Cat engine, only purchase Cat fluids and Cat filters through your Cat dealer or Cat authorized outlets. For a list of authorized Cat parts outlets in your area, consult your Cat dealer.If you purchase what appear to be Cat fluids and/or Cat filters through other outlets/sources, you are at a very high risk of purchasing counterfeit ("look-alike") products.Counterfeit or "look-alike" products may visually appear the same as the original Cat product, but the product performance and internal quality will typically be very low.Counterfeit or "look-alike" products have a very high likelihood of causing and/or allowing engine and/or machine compartment damage.

Follow all industry standard safety practices when operating engines and/or machines and when performing all recommended and/or required maintenance.Note: Instructions for the installation of the filter are printed on the side of each Cat spin-on filter. For non-Cat filters, refer to the installation instructions that are provided by the supplier of the filter.

In order to meet expected fuel system component life, 4 micron(c) absolute or less secondary fuel filtration is required for all Cat diesel engines that are equipped with common-rail fuel systems. Also, 4 micron(c) absolute or less secondary fuel filtration is required for all Cat diesel engines that are equipped with unit injected fuel systems. For all other Cat diesel engines (mostly older engines with pump, line and nozzle type fuel systems), the use of 4 micron(c) absolute or less secondary fuel filtration is strongly recommended. Note that all current Cat diesel engines are factory equipped with Cat Advanced Efficiency 4 micron(c) absolute fuel filters.In order to obtain additional information on Cat designed and produced filtration products, refer to the "Reference Material" article, "Filters" and "Miscellaneous" topics in this Special Publication. Consult your Cat dealer for assistance with filtration recommendations for your Cat machine.

Caterpillar does not warrant the quality or performance of non-Caterpillar fluids and filters.

General Recommendations and Guidelines

Follow all applicable industry standards and all applicable governmental, environmental, and safety guidelines, practices, regulations, and mandates.Note: These general recommendations and guidelines concerning maintenance and care of fuel and fuel storage systems are not intended to be all inclusive. Discuss proper fuel safety and health, handling, and maintenance practices with your fuel supplier. Use of these general recommendations and guidelines does not lessen the engine owners and/or fuel supplier responsibility. All industry standard practices for fuel storage and for fuel handling must be followed.Note: Where recommendations for draining water and/or sediment and/or debris are stated, dispose of this waste according to all applicable regulations and mandates.Note: Cat filters are designed and built to provide optimal performance and protection of the fuel system components.

Discuss application-specific fuel concerns, needs, and requirements with a reputable fuel supplier.

Purchase fuel from a reputable supplier.

Use fuel that meets or exceeds Cat requirements for distillate diesel fuel. Refer to the "Cat Specification for Distillate Diesel Fuel for Nonroad Diesel Engines" table in this Special Publication, "Distillate Diesel Fuel" article.

Confirm with the filter manufacturer that the

Have questions with 106691-6571?

Group cross 106691-6571 ZEXEL

Isuzu

106691-6571

1156009524

INJECTION-PUMP ASSEMBLY

6RB1

6RB1