Information injection-pump assembly

ZEXEL

106691-6561

1066916561

ISUZU

1156007575

1156007575

Rating:

Service parts 106691-6561 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-041-2

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106691-6561

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106691-6561

1066916561

ISUZU

1156007575

1156007575

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

B

Rack position

8.9

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

133.9

131.9

135.9

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.3+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.4

15.8

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500

Advance angle

deg.

0.3

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

1

0.1

1

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.2

0.7

1.7

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

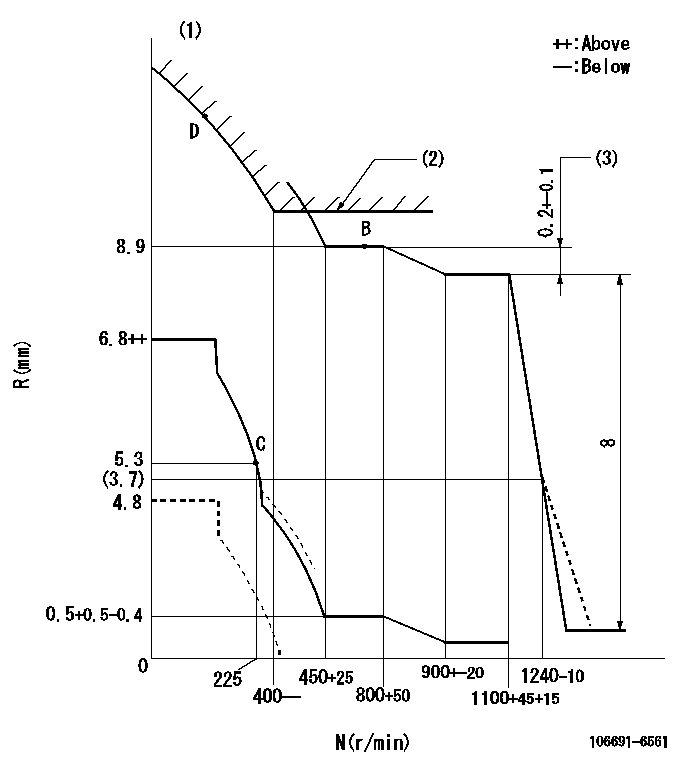

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

(3)Rack difference between N = N1 and N = N2

----------

DL=3.7-0.5mm SXL=9.2+0.2mm N1=1100r/min N2=650r/min

----------

----------

DL=3.7-0.5mm SXL=9.2+0.2mm N1=1100r/min N2=650r/min

----------

0000000901

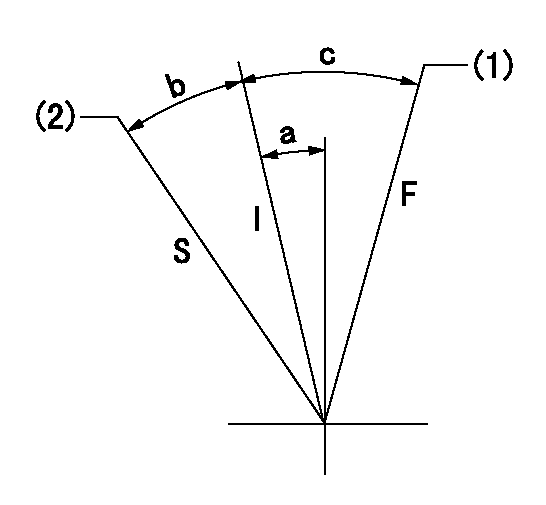

F:Full load

I:Idle

S:Stop

(1)Attach the return spring to the upper hole and adjust.

(2)Rack position aa (pump speed bb r/min )

----------

aa=4.8mm bb=0r/min

----------

a=1.5deg+-5deg b=15deg+-5deg c=31deg+-3deg

----------

aa=4.8mm bb=0r/min

----------

a=1.5deg+-5deg b=15deg+-5deg c=31deg+-3deg

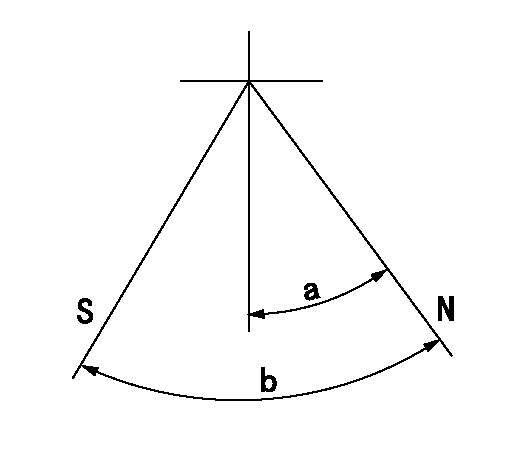

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=32deg+-5deg b=64deg+-5deg

----------

----------

a=32deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=21deg

----------

a=(70deg)

----------

aa=21deg

----------

a=(70deg)

Information:

The current API categories represent the minimum requirements for diesel engine oils. These categories are developed in collaboration of OEMs and the Oil and Chemical industries.The current licensed oils are:

API CK-4, released December 2016

API CJ-4, released 2006

API CI-4, API CI-4PLUS released 2002

API CH-4, released 1998Each API category is technically more advanced and of higher performance than the prior one.Refer to API 1509 document and/or ASTM D4485 for details of the API tests requirements and limits.Note: Obsolete API oil categories are not licensed by the API and hence are of uncontrolled quality. These oils are technically inferior to current oils and can result in reduced engine performance and life. These obsolete oil categories are not allowed in Cat engines.API FA-4 is NOT recommended for Caterpillar engines. API FA oil is designed with low High Temperature High Shear (HTHS) viscosity oil for use in certain 2017 On-Highway truck engines that have to meet certain on-road emissions regulations. This category is not backwards compatible.In order to help protect your engine, and in order to help optimize oil drain intervals for engine applications and duty cycles, use Cat S O S Services oil analysis. Refer to the section below and to the section on Cat S O S Services given later in the Special Publication.

Depending on application severity and localized environmental conditions, and also depending on maintenance practices, operating Direct Injection (DI) diesel engines and operating PC (Precombustion Chamber) diesel engines on fuel with sulfur levels over 0.1 percent (1000 ppm) may require significantly shortened oil change intervals in order to help maintain adequate wear protection. Refer to this Special Publication, "Fuel Specifications" section, “Diesel Fuel Sulfur” topic for additional information.

Fuel Sulfur Impact on Engine Oil

The use of Cat S O S Services oil analysis is recommended for determining oil life.For Caterpillar machines operating under emissions regulations such as US EPA Tier4, EU Stage V or other emission regulations controls, the maximum fuel sulfur level permitted by regulations in the US is 0.0015% or 15 ppm. Maximum permitted fuel sulfur levels in other emissions regulated countries may vary from .0015% or 15 ppm slightly and must be followed.In order to help protect your engine and optimize oil drain intervals for engine applications and duty cycles, it is important to use SOS Services oil analysis to determine if the sulfur has degraded the oil. Use Cat S O S Services oil analysis per the following general guidelines:

Recommended normally

For fuel sulfur level up to 0.05 percent (500 ppm), no additional sampling is required. Follow the recommended oil sampling in the machine OMM

For fuel sulfur level of > 0.05 percent to 0.5 percent (500 ppm to 5000 ppm), SOS services oil analysis is strongly recommended to determine oil drain intervals. Sample the oil every 250 hours until a trend is established,

API CK-4, released December 2016

API CJ-4, released 2006

API CI-4, API CI-4PLUS released 2002

API CH-4, released 1998Each API category is technically more advanced and of higher performance than the prior one.Refer to API 1509 document and/or ASTM D4485 for details of the API tests requirements and limits.Note: Obsolete API oil categories are not licensed by the API and hence are of uncontrolled quality. These oils are technically inferior to current oils and can result in reduced engine performance and life. These obsolete oil categories are not allowed in Cat engines.API FA-4 is NOT recommended for Caterpillar engines. API FA oil is designed with low High Temperature High Shear (HTHS) viscosity oil for use in certain 2017 On-Highway truck engines that have to meet certain on-road emissions regulations. This category is not backwards compatible.In order to help protect your engine, and in order to help optimize oil drain intervals for engine applications and duty cycles, use Cat S O S Services oil analysis. Refer to the section below and to the section on Cat S O S Services given later in the Special Publication.

Depending on application severity and localized environmental conditions, and also depending on maintenance practices, operating Direct Injection (DI) diesel engines and operating PC (Precombustion Chamber) diesel engines on fuel with sulfur levels over 0.1 percent (1000 ppm) may require significantly shortened oil change intervals in order to help maintain adequate wear protection. Refer to this Special Publication, "Fuel Specifications" section, “Diesel Fuel Sulfur” topic for additional information.

Fuel Sulfur Impact on Engine Oil

The use of Cat S O S Services oil analysis is recommended for determining oil life.For Caterpillar machines operating under emissions regulations such as US EPA Tier4, EU Stage V or other emission regulations controls, the maximum fuel sulfur level permitted by regulations in the US is 0.0015% or 15 ppm. Maximum permitted fuel sulfur levels in other emissions regulated countries may vary from .0015% or 15 ppm slightly and must be followed.In order to help protect your engine and optimize oil drain intervals for engine applications and duty cycles, it is important to use SOS Services oil analysis to determine if the sulfur has degraded the oil. Use Cat S O S Services oil analysis per the following general guidelines:

Recommended normally

For fuel sulfur level up to 0.05 percent (500 ppm), no additional sampling is required. Follow the recommended oil sampling in the machine OMM

For fuel sulfur level of > 0.05 percent to 0.5 percent (500 ppm to 5000 ppm), SOS services oil analysis is strongly recommended to determine oil drain intervals. Sample the oil every 250 hours until a trend is established,