Information injection-pump assembly

ZEXEL

106691-6530

1066916530

ISUZU

1156009331

1156009331

Rating:

Cross reference number

ZEXEL

106691-6530

1066916530

ISUZU

1156009331

1156009331

Zexel num

Bosch num

Firm num

Name

106691-6530

1156009331 ISUZU

INJECTION-PUMP ASSEMBLY

E120 * K

E120 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.6

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

110.2

108.2

112.2

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

22.5

19.3

25.7

Max. variation between cylinders

%

0

-1.3

1.3

Fixing the rack

*

Timer adjustment

Pump speed

r/min

700+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.7

0.2

1.2

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

2.7

2.2

3.2

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

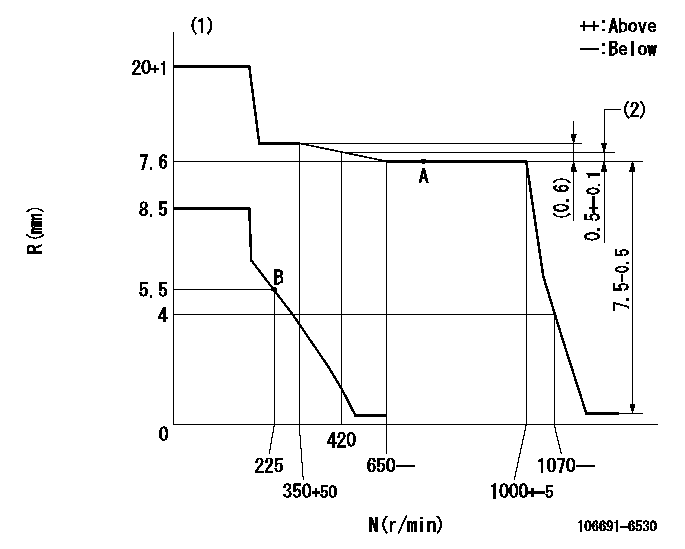

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=10 N1=700r/min N2=420r/min

----------

----------

K=10 N1=700r/min N2=420r/min

----------

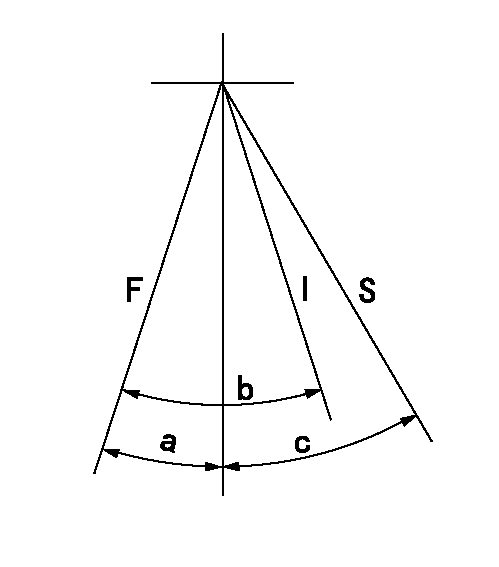

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=8deg+-5deg b=23deg+-5deg c=32deg+-3deg

----------

----------

a=8deg+-5deg b=23deg+-5deg c=32deg+-3deg

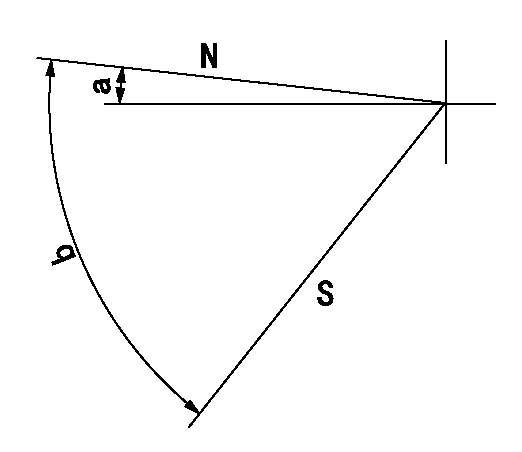

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=3deg+-5deg b=46deg+-5deg

----------

----------

a=3deg+-5deg b=46deg+-5deg

Information:

Do not use a commercial coolant/antifreeze that only meets the ASTM "D3306" specification. This type of coolant/antifreeze is made for light duty automotive applications.Use only the coolant/antifreeze that is recommended.

Caterpillar recommends a 1:1 mixture of properly inhibited distilled or deionized water and glycol. This mixture will provide optimum heavy-duty performance as a coolant/antifreeze.Note: Cat DEAC does not require a treatment with an SCA at the initial fill. However, a commercial heavy-duty coolant/antifreeze that only meets "ASTM D4985", by specification, WILL require a treatment with an SCA at the initial fill. A commercial heavy-duty coolant/antifreeze that meets the "ASTM D6210" specification WILL NOT require a treatment with an SCA at the initial fill. Read the label or the instructions that are provided by the manufacturer of the commercial heavy-duty coolant/antifreeze.Note: When adding SCA at initial fill to a coolant/antifreeze that only meets the "ASTM D4985", ensure the SCA is compatible with the antifreeze/coolant. For example, a HOAT coolant that meets the "ASTM D4985" specification may not be compatible with an SCA designed for use with conventional coolants. It is the responsibility of the coolant manufacturer to provide sources of compatible SCAs. It is the responsibility of the coolant manufacturer and SCA manufacturer to demonstrate a positive influence on reducing cavitation corrosion in an operating diesel engine.Note: These coolants WILL require a treatment with a supplemental coolant additive on a maintenance basis.Note: When adding SCA at initial fill to a coolant/antifreeze that only meets the "ASTM D4985", it is a collective responsibility of the user, coolant manufacturer, and SCA manufacturer to ensure the SCA is compatible with the antifreeze/coolant based on the recommendations provided by the coolant manufacturer and SCA manufacturer. One of the test methods required to be used to help ensure SCA compatibility with the antifreeze/coolant concentrate is "ASTM D5828-97". 6% SCA in the solution that is 60 parts antifreeze/coolant of interest, 34 parts water, and 6 parts SCA must have no more than 0.1 mL of formed insolubles. 12% SCA in a solution that is 60 parts antifreeze/coolant of interest, 28 parts water, and 12 parts SCA must have no more than 2 mL of formed insolubles. The SCA manufacturer is responsible for ensuring their SCA is compatible with water meeting the "Caterpillar Minimum Acceptable Water Quality Requirements" as found in this Special Publication and as found in "ASTM D6210-06", Table X1.1.

All Cat diesel engines equipped with air-to-air aftercooling (ATAAC) require a minimum of 30 percent glycol in order to help prevent water pump cavitation.

Note: Refer to the engine Operation and Maintenance Manual for exceptions.

Table 1

Service Life Before Flushing and Before Refilling

Coolant Service Life (1) (2) (3)

Cat ELC 965,606 kilometers (600,000 miles)

12000 hours

6 years (4)

Commercial coolant that meets the Caterpillar EC-1 specification

482,803 kilometers (300,000 miles)

6000 hours

6 years (5)

Cat DEAC

321,869 kilometers (200,000 miles)

3000 hours

3 years

Commercial Heavy-Duty Coolant/Antifreeze that meets "ASTM D4985" or "ASTM D6210"

241,402 kilometers (150,000 miles)

3000 hours

1 year

Have questions with 106691-6530?

Group cross 106691-6530 ZEXEL

Isuzu

106691-6530

1156009331

INJECTION-PUMP ASSEMBLY

E120

E120