Information injection-pump assembly

ZEXEL

106691-6260

1066916260

ISUZU

1156006221

1156006221

Rating:

Service parts 106691-6260 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-041-2

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106691-6260

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106691-6260

1066916260

ISUZU

1156006221

1156006221

Zexel num

Bosch num

Firm num

Name

106691-6260

1156006221 ISUZU

INJECTION-PUMP ASSEMBLY

E120T * K 14CA PE6P,6PD PE

E120T * K 14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

90.4

88.4

92.4

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

152

148.2

155.8

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

6+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

11.8

8.6

15

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Timer adjustment

Pump speed

r/min

700+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.7

0.2

1.2

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

2.7

2.2

3.2

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

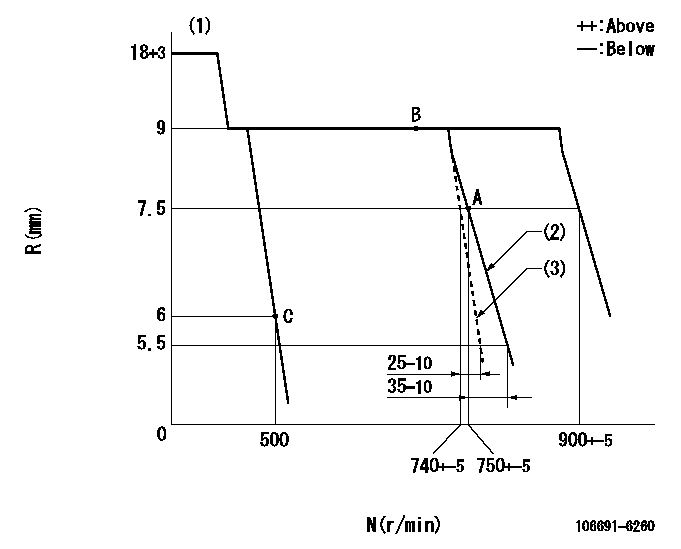

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set idle sub-spring

(3)Set the governor spring.

----------

K=9

----------

----------

K=9

----------

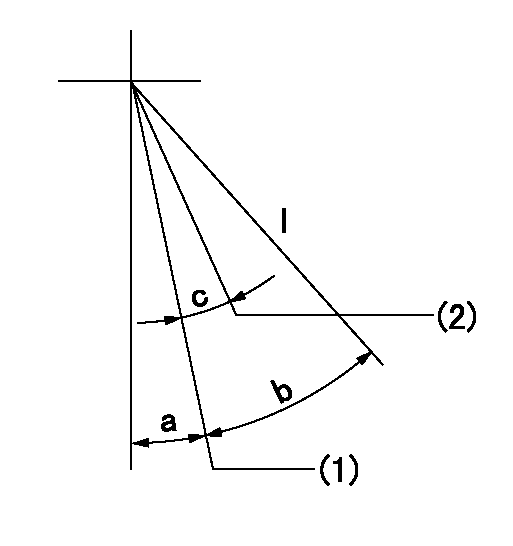

Speed control lever angle

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=4deg+-5deg b=13deg+-5deg c=5deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=4deg+-5deg b=13deg+-5deg c=5deg+-5deg

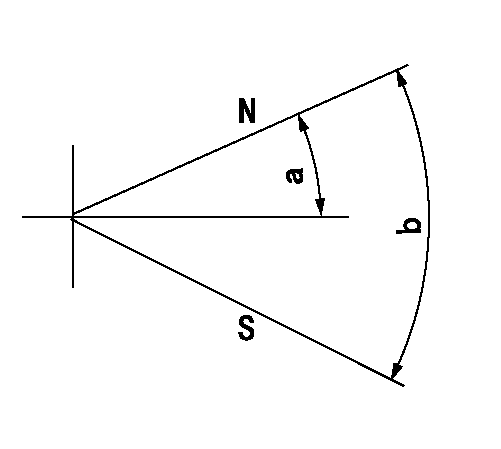

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=10deg+-5deg b=53deg+-5deg

----------

----------

a=10deg+-5deg b=53deg+-5deg

Information:

Operating Recommendations

The following guidelines are recommended when you use the monitor.

Avoid turning the system on and off frequently.

Never turn off the system when the indicator light for the hard drive is illuminated.

Always use the proper power down procedures as required by your operating system such as the "Shut Down" command in Microsoft Windows.

Do not turn off the monitor until a message appears. The message tells you that turning off the monitor is safe.

Do not operate the monitor when the covers are removed. An electrical shock hazard exists. In addition, removing the covers will disrupt the air flow. Removing the covers may result in overheating. All of the covers are required to maintain the EMI shield.Note: After you shut off the system, do not move the monitor or turn on the monitor. Wait until the hard drive has come to a complete stop (30 seconds). If you are using an external monitor, turn on the monitor first.Operator Access

Operator access is limited to the front panel of the monitor. The front panel includes the display and the touchscreen. Only authorized personnel and properly trained personnel are allowed access to other components.System Checkout

In order to power up the system, perform the following procedure:

Apply power to the monitor. The monitor performs a POST. During the test, the monitor checks the following devices: the processor board, the memory, the keyboard and certain peripheral devices.

The monitor displays the progress of the POST and the initialization of accessory devices.

If the system does not power up, or you notice other problems, refer to Troubleshooting, "Troubleshooting Checks".

The monitor will then display the start-up dialogs for the operating system that has been installed. If no software is installed, the following prompt is displayed:

Table 1

Insert bootable media in the appropriate drive. System Reset

In order to reset the monitor, press the following keys simultaneously: "Ctrl", "Alt" and "Delete". The keys are located on an attached keyboard. Follow the instructions for the operating system. During the reset, the monitor performs the following tasks:

Clears the RAM

Starts the POST

Initializes peripheral devices, such as drives and printers

Loads the operating system (if installed)After the reset, the monitor begins the POST.

The following guidelines are recommended when you use the monitor.

Avoid turning the system on and off frequently.

Never turn off the system when the indicator light for the hard drive is illuminated.

Always use the proper power down procedures as required by your operating system such as the "Shut Down" command in Microsoft Windows.

Do not turn off the monitor until a message appears. The message tells you that turning off the monitor is safe.

Do not operate the monitor when the covers are removed. An electrical shock hazard exists. In addition, removing the covers will disrupt the air flow. Removing the covers may result in overheating. All of the covers are required to maintain the EMI shield.Note: After you shut off the system, do not move the monitor or turn on the monitor. Wait until the hard drive has come to a complete stop (30 seconds). If you are using an external monitor, turn on the monitor first.Operator Access

Operator access is limited to the front panel of the monitor. The front panel includes the display and the touchscreen. Only authorized personnel and properly trained personnel are allowed access to other components.System Checkout

In order to power up the system, perform the following procedure:

Apply power to the monitor. The monitor performs a POST. During the test, the monitor checks the following devices: the processor board, the memory, the keyboard and certain peripheral devices.

The monitor displays the progress of the POST and the initialization of accessory devices.

If the system does not power up, or you notice other problems, refer to Troubleshooting, "Troubleshooting Checks".

The monitor will then display the start-up dialogs for the operating system that has been installed. If no software is installed, the following prompt is displayed:

Table 1

Insert bootable media in the appropriate drive. System Reset

In order to reset the monitor, press the following keys simultaneously: "Ctrl", "Alt" and "Delete". The keys are located on an attached keyboard. Follow the instructions for the operating system. During the reset, the monitor performs the following tasks:

Clears the RAM

Starts the POST

Initializes peripheral devices, such as drives and printers

Loads the operating system (if installed)After the reset, the monitor begins the POST.

Have questions with 106691-6260?

Group cross 106691-6260 ZEXEL

Isuzu

106691-6260

1156006221

INJECTION-PUMP ASSEMBLY

E120T

E120T