Information injection-pump assembly

ZEXEL

106691-3020

1066913020

HINO

220201480A

220201480a

Rating:

Cross reference number

ZEXEL

106691-3020

1066913020

HINO

220201480A

220201480a

Zexel num

Bosch num

Firm num

Name

106691-3020

220201480A HINO

INJECTION-PUMP ASSEMBLY

ER100 * K

ER100 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

177

143

211

Overflow valve opening pressure

kgf/cm2

1.8

1.45

2.15

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.45

3.4

3.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

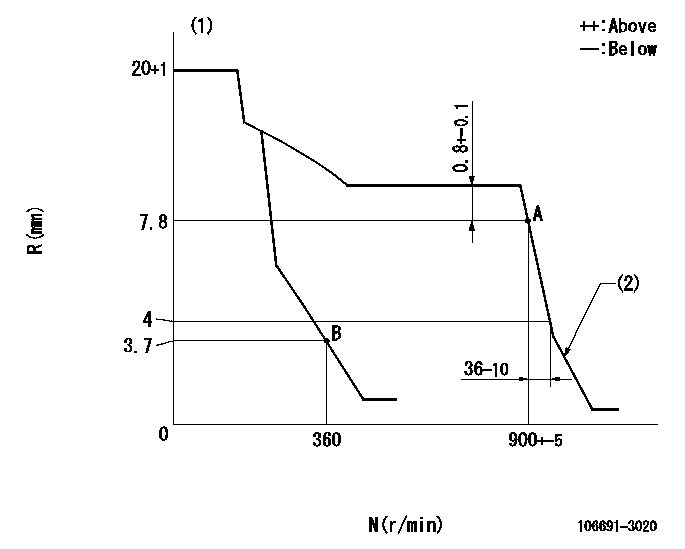

Injection quantity adjustment

Adjusting point

A

Rack position

7.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

97.5

95.5

99.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

3.7+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

8.2

5.2

11.2

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.3

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2

2

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Idle sub spring setting: L1.

----------

K=5 L1=4.5+-0.2mm

----------

----------

K=5 L1=4.5+-0.2mm

----------

Speed control lever angle

F:Full speed

I:Idle

----------

----------

a=1deg+-5deg b=22deg+-5deg

----------

----------

a=1deg+-5deg b=22deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Information:

Test Procedure

System Operation

The SLC 5/04 diagnostic indicators are located on the front of the following components: Power Supply, CPU and I/O Modules.The diagnostic indicators help trace the source of the fault. Faults can be found in the following components: Input devices, Output devices, Wiring and The controller.The green "DH+" LED is flashing. There are no active nodes on the network.The red "DH+" LED is flashing. There are duplicate active nodes on the link with the same address.The red "FLT" LED is flashing during operation. The processor detects a major fault. The fault is in the processor expansion chassis or the fault is in the memory.

Illustration 1 g00563551

Diagram of the LED indicators

Illustration 2 g00562937

Functional Test

Check the electrical connectors and check the wiring.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Disconnect the power supply.

Check the electrical connectors and check the wiring for damage or bad connections.

Verify that all modules are properly seated.

Verify the status of the LED on the SLC 5/04.The results of the preceding procedure are in the following list:

All of the components are fully installed. All of the components are free of corrosion. All of the components are free of damage. All of the modules are properly seated. Proceed to 2.

The components are not fully installed. The components are not free of corrosion. The components are damaged. All of the modules are not properly seated. Repair the component. Verify that the repair resolves the problem. STOP.

Check the communication parameters of the customer supplied devices.

Check the communication parameter of the programmer.The results of the preceding procedure are in the following list:

The programmer address and the processor address are different. Proceed to 3.

The programmer address and the processor address are not different. Set the addresses. Verify that the repair resolves the problem. Stop.

Change the baud rate.

Change the baud rate of the programmer and change the baud rate of the processor.

Increase the maximum node address.Note: The default baud rate is 57,600. The default node address is one.The results of the preceding procedure are in the following list:

No errors are displayed on the LED indicators. Stop.

Errors are displayed on the LED indicators. Proceed to 4.

Check line voltage.

Measure the line voltage at the terminals.

Verify the voltage of the power supply. The power supply voltage should be measured between 21.0 VDC and 28.0 VDC.The results of the preceding procedure are in the following list:

The line voltage is in the range. Replace the processor. Verify that the repair solves the problem. Refer to Maintenance Procedure, "Processor - Replace".

The line voltage is out of the range. Refer to Troubleshooting, "System Power". Stop.

System Operation

The SLC 5/04 diagnostic indicators are located on the front of the following components: Power Supply, CPU and I/O Modules.The diagnostic indicators help trace the source of the fault. Faults can be found in the following components: Input devices, Output devices, Wiring and The controller.The green "DH+" LED is flashing. There are no active nodes on the network.The red "DH+" LED is flashing. There are duplicate active nodes on the link with the same address.The red "FLT" LED is flashing during operation. The processor detects a major fault. The fault is in the processor expansion chassis or the fault is in the memory.

Illustration 1 g00563551

Diagram of the LED indicators

Illustration 2 g00562937

Functional Test

Check the electrical connectors and check the wiring.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Disconnect the power supply.

Check the electrical connectors and check the wiring for damage or bad connections.

Verify that all modules are properly seated.

Verify the status of the LED on the SLC 5/04.The results of the preceding procedure are in the following list:

All of the components are fully installed. All of the components are free of corrosion. All of the components are free of damage. All of the modules are properly seated. Proceed to 2.

The components are not fully installed. The components are not free of corrosion. The components are damaged. All of the modules are not properly seated. Repair the component. Verify that the repair resolves the problem. STOP.

Check the communication parameters of the customer supplied devices.

Check the communication parameter of the programmer.The results of the preceding procedure are in the following list:

The programmer address and the processor address are different. Proceed to 3.

The programmer address and the processor address are not different. Set the addresses. Verify that the repair resolves the problem. Stop.

Change the baud rate.

Change the baud rate of the programmer and change the baud rate of the processor.

Increase the maximum node address.Note: The default baud rate is 57,600. The default node address is one.The results of the preceding procedure are in the following list:

No errors are displayed on the LED indicators. Stop.

Errors are displayed on the LED indicators. Proceed to 4.

Check line voltage.

Measure the line voltage at the terminals.

Verify the voltage of the power supply. The power supply voltage should be measured between 21.0 VDC and 28.0 VDC.The results of the preceding procedure are in the following list:

The line voltage is in the range. Replace the processor. Verify that the repair solves the problem. Refer to Maintenance Procedure, "Processor - Replace".

The line voltage is out of the range. Refer to Troubleshooting, "System Power". Stop.

Have questions with 106691-3020?

Group cross 106691-3020 ZEXEL

Hino

106691-3020

220201480A

INJECTION-PUMP ASSEMBLY

ER100

ER100