Information injection-pump assembly

ZEXEL

106691-2080

1066912080

Rating:

Cross reference number

ZEXEL

106691-2080

1066912080

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

132.3

129.3

135.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

49.3

49.3

Boost pressure

mmHg

370

370

Injection quantity adjustment_02

Adjusting point

B

Rack position

4+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.9

8.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

4.9+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

12.7

10.8

14.6

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

(check)

(check)

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

9.6

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

10.6

Boost pressure

kPa

36

29.3

42.7

Boost pressure

mmHg

270

220

320

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

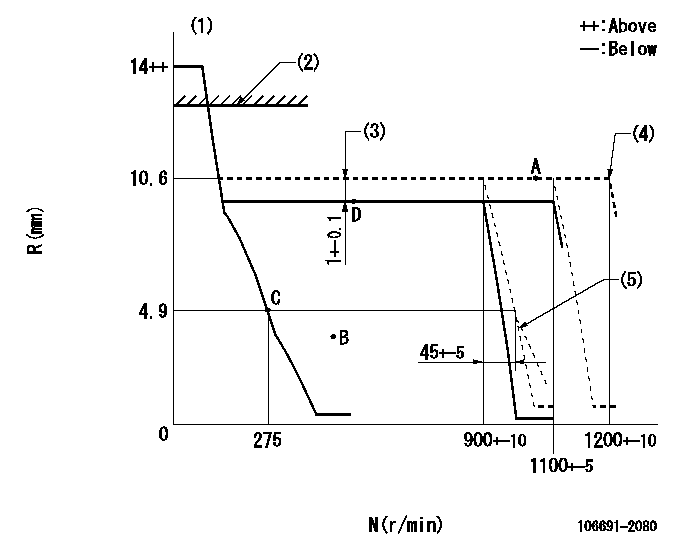

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Boost compensator stroke

(4)At shipping

(5)Idle sub spring setting: L1.

----------

K=12 RAL=14+0.2mm L1=4.8+-0.1mm

----------

----------

K=12 RAL=14+0.2mm L1=4.8+-0.1mm

----------

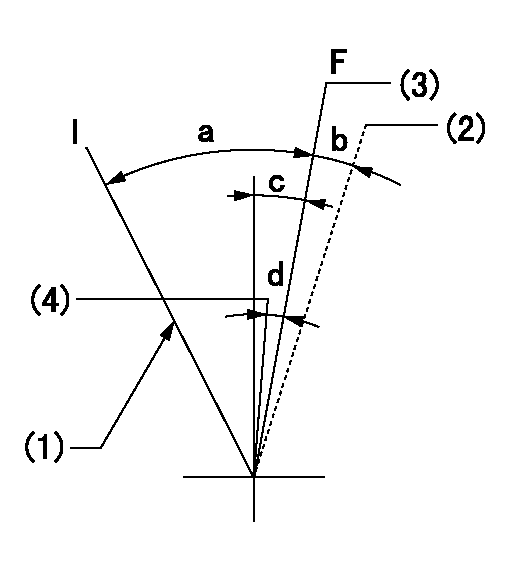

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=1100r/min bb=900r/min

----------

a=32deg+-5deg b=(5deg) c=9deg+-5deg d=8deg+-5deg

----------

aa=1100r/min bb=900r/min

----------

a=32deg+-5deg b=(5deg) c=9deg+-5deg d=8deg+-5deg

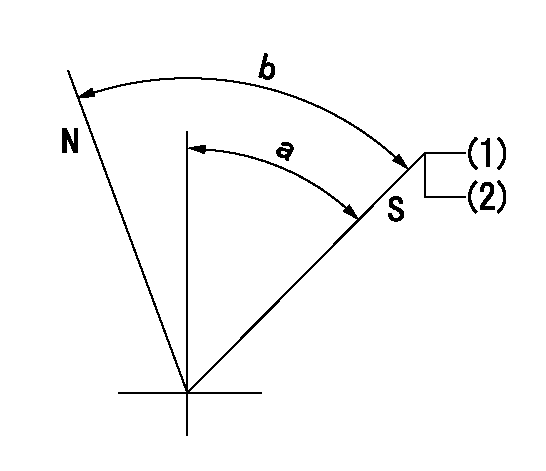

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa, rack position bb

(2)Stopper bolt setting

----------

aa=0r/min bb=1-0.2mm

----------

a=50deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.2mm

----------

a=50deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(4deg)

----------

----------

a=(4deg)

Information:

The RTD Module Status LED

The module status LED indicators are used in order to indicate operating errors or module errors. You can not recover from the module errors. When an error is present, the RTD module no longer communicates to the processor. The channel states are disabled and the data words are cleared.The RTD Module LED Indicators

Illustration 18 g00563392

The "Module Status" LED is on. The "Channel Status" LED is flashing. Refer to Troubleshooting, "Resistance Temperature Detector".

Illustration 19 g00563417

The "Module Status" LED is off. Cycle the power and refer to Troubleshooting, "Resistance Temperature Detector".Modbus Module

The Modbus module allows an Allen-Bradley SLC 500 to interface with devices that are compatible with Modbus. The module allows a remote access to the MMS.Port Information for the Modbus Module

Illustration 20 g00563418

Information for port 1 is in the following list:

RS-485

1 stop bit and no parity

RTU slave

Baud Rate from the "Setup" Screen

Address from the "Setup" ScreenInformation for port 2 is in the following list:

RS-232

1 stop bit and no parity

RTU slave

Baud Rate from the "Setup" Screen

Address from the "Setup" ScreenJumper Settings for the Modbus Module

Illustration 21 g00563421

Troubleshooting the Modbus Module

Illustration 22 g00563423

Table 1

LED Name Color Status Indication

CFG Green Off The normal state of the LED. No configuration related activity is occurring.

The module status LED indicators are used in order to indicate operating errors or module errors. You can not recover from the module errors. When an error is present, the RTD module no longer communicates to the processor. The channel states are disabled and the data words are cleared.The RTD Module LED Indicators

Illustration 18 g00563392

The "Module Status" LED is on. The "Channel Status" LED is flashing. Refer to Troubleshooting, "Resistance Temperature Detector".

Illustration 19 g00563417

The "Module Status" LED is off. Cycle the power and refer to Troubleshooting, "Resistance Temperature Detector".Modbus Module

The Modbus module allows an Allen-Bradley SLC 500 to interface with devices that are compatible with Modbus. The module allows a remote access to the MMS.Port Information for the Modbus Module

Illustration 20 g00563418

Information for port 1 is in the following list:

RS-485

1 stop bit and no parity

RTU slave

Baud Rate from the "Setup" Screen

Address from the "Setup" ScreenInformation for port 2 is in the following list:

RS-232

1 stop bit and no parity

RTU slave

Baud Rate from the "Setup" Screen

Address from the "Setup" ScreenJumper Settings for the Modbus Module

Illustration 21 g00563421

Troubleshooting the Modbus Module

Illustration 22 g00563423

Table 1

LED Name Color Status Indication

CFG Green Off The normal state of the LED. No configuration related activity is occurring.