Information injection-pump assembly

BOSCH

9 400 617 777

9400617777

ZEXEL

106691-2061

1066912061

MITSUBISHI

ME050846

me050846

Rating:

Service parts 106691-2061 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME059740

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

106691-2061

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 777

9400617777

ZEXEL

106691-2061

1066912061

MITSUBISHI

ME050846

me050846

Zexel num

Bosch num

Firm num

Name

106691-2061

9 400 617 777

ME050846 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22TC K

6D22TC K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

132.3

129.3

135.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

4+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.9

8.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

4.9+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

12.7

10.8

14.6

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

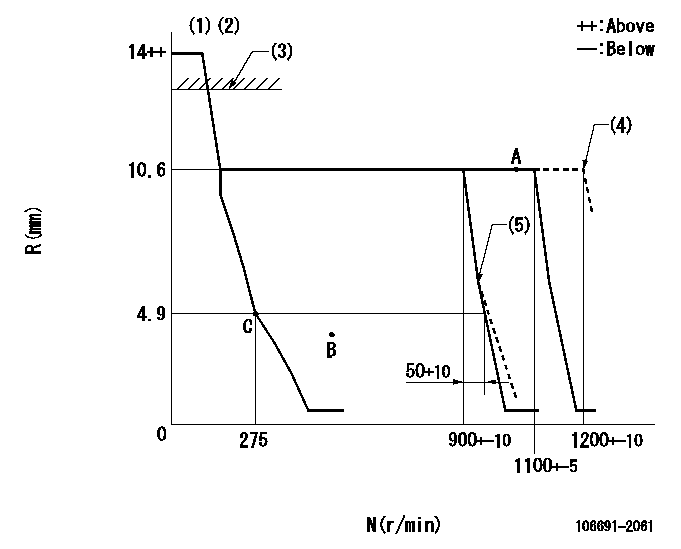

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

(3)RACK LIMIT: RAL

(4)At shipping

(5)Idle sub spring setting: L1.

----------

K=15 RAL=14+0.2mm L1=5.4+-0.1mm

----------

----------

K=15 RAL=14+0.2mm L1=5.4+-0.1mm

----------

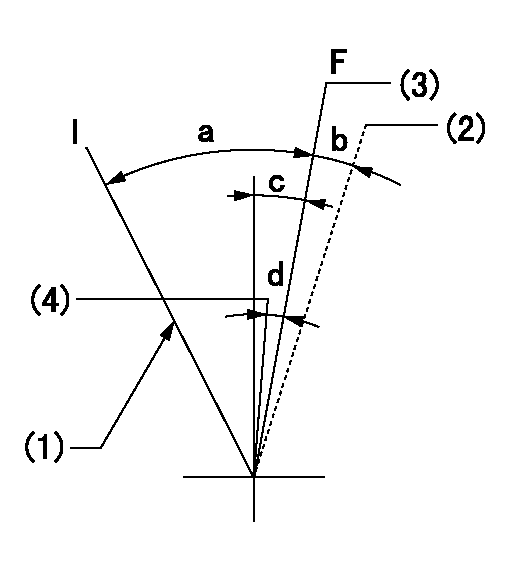

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=1100r/min bb=900r/min

----------

a=32deg+-5deg b=(5deg) c=12deg+-5deg d=8deg+-5deg

----------

aa=1100r/min bb=900r/min

----------

a=32deg+-5deg b=(5deg) c=12deg+-5deg d=8deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Table 1

Conversion Table

Current Hertz RPM

4.0 0 0

4.5 159 38

5.0 319 75

5.5 478 113

6.0 638 150

6.5 797 188

7.0 956 225

7.5 1116 263

8.0 1275 300

8.5 1434 338

9.0 1594 375

9.5 1753 413

10.0 1913 450

10.5 2072 488

11.0 2231 525

11.5 2391 563

12.0 2550 600

12.5 2709 638

13.0 2869 675

13.5 3028 713

14.0 3188 750

14.5 3347 788

15.0 3506 825

15.5 3666 863

16.0 3825 900

16.5 3984 938

17.0 4144 975

17.5 4303 1013

18.0 4463 1050

18.5 4622 1088

19.0 4781 1125

19.5 4941 1163

20.0 5100 1200

Illustration 5 g00562935

Calibrate the transmitter.

Disconnect the wiring from the transmitter.

Ensure that the resistor is located on the input side of the transmitter. The resistor should be across the positive terminal and the negative terminal.

Connect an ammeter and a signal generator as you are shown in illustration 5.

Ensure that the signal generator is not generating a signal (zero Hertz).

Adjust the zero dial until the ammeter reads 4 mA.

Adjust the signal generator in order to produce an output of 5100 HZ.

Adjust the span dial until the ammeter reads 20 mA.

Adjust the signal generator in order to produce an output of zero hertz. Verify that the ammeter reads 4 mA.

The ammeter reads 4 mA. STOP.

The ammeter does not read 4 mA. Proceed to 3.

Readjust the frequency input.

Adjust the signal generator in order to produce zero Hertz.

Adjust the zero dial until the ammeter reads 4 mA.

Adjust the signal generator in order to produce an output of 5100 HZ.

Adjust the span dial until the ammeter reads 20 mA.

Adjust the signal generator in order to produce an output of zero hertz. Verify that the ammeter reads 4 mA.Note: Repeat the procedure in order to calibrate a frequency transmitter properly. Continue until both the 4 mA and the 20 mA readings are correct.

The ammeter reads 4 mA and 20 mA at the desired input frequency. STOP.

The ammeter does not read 4 mA and 20 mA. Replace the transmitter. Verify that this repair eliminates the problem.Magnetic Pickup Sensor

The magnetic pickup sensor sends the engine speed signal to the engine speed switch and to the transmitter.

Illustration 6 g00562936

Setting and Adjustment

Adjust the sensor's clearance from the flywheel.

The engine is secured. Install the sensor until the sensor contacts the flywheel.

Back off the sensor (1.2 0.1 turns).

Measure clearance between the flywheel and the

Have questions with 106691-2061?

Group cross 106691-2061 ZEXEL

Mitsubishi

106691-2061

9 400 617 777

ME050846

INJECTION-PUMP ASSEMBLY

6D22TC

6D22TC