Information injection-pump assembly

ZEXEL

106691-2060

1066912060

Rating:

Cross reference number

ZEXEL

106691-2060

1066912060

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

132.3

129.3

135.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

4+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.9

8.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

4.9+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

12.7

10.8

14.6

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

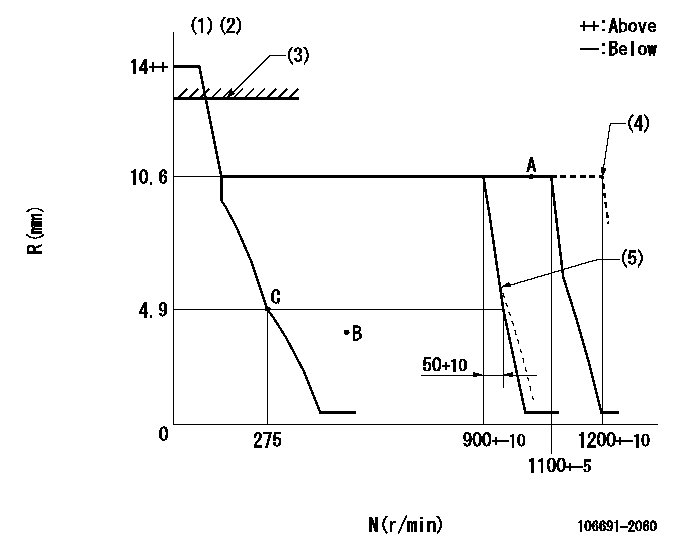

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

(3)RACK LIMIT: RAL

(4)At shipping

(5)Idle sub spring setting: L1.

----------

K=15 RAL=14+0.2mm L1=5.4+-0.1mm

----------

----------

K=15 RAL=14+0.2mm L1=5.4+-0.1mm

----------

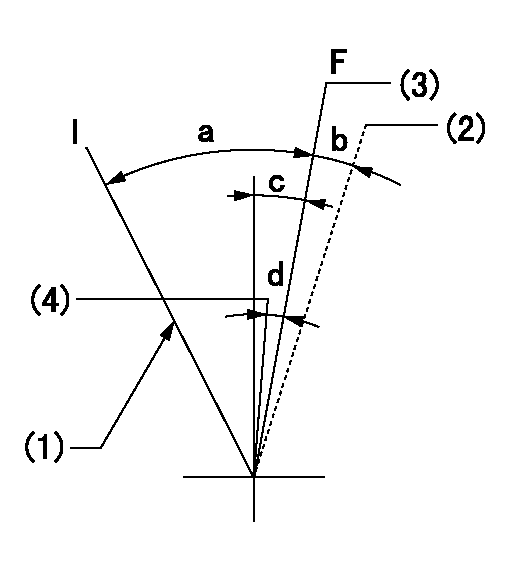

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=1100r/min bb=900r/min

----------

a=32deg+-5deg b=(5deg) c=12deg+-5deg d=8deg+-5deg

----------

aa=1100r/min bb=900r/min

----------

a=32deg+-5deg b=(5deg) c=12deg+-5deg d=8deg+-5deg

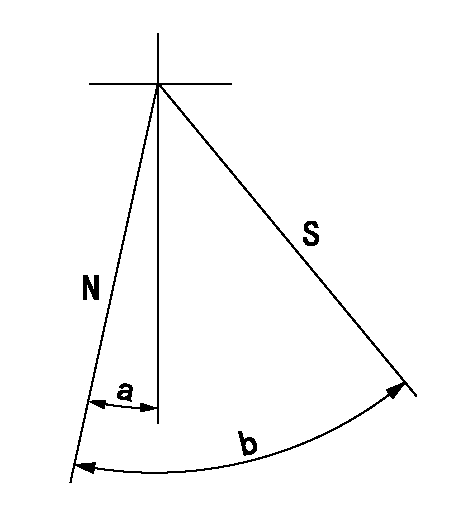

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(4deg)

----------

----------

a=(4deg)

Information:

Shutdowns

A shutdown secures the fuel and a shutdown secures the air to the engine. A fuel shutoff solenoid may be located in the fuel actuator. The fuel shutoff solenoid is energized. The injector is driven to the off position. This secures the fuel.The air shutoff solenoid secures the air. When this solenoid is activated compressed air flows to the air damper. The air releases a pin. When the pin is released, a spring closes the air damper. This secures the combustion air supply from the turbochargers to the aftercooler.Note: The air damper must be MANUALLY reset before the engine can be restarted. The Marine Engine Control Panel must also be reset with the "RESET" switch before the MMS will allow starting. The panel may not be reset until the engine has stopped rotating. Determine the cause of the shutdown and correct the problem prior to engine operation.

Table 2

Shutdowns of the Marine Monitoring System

Description Sensor Location

Group Part Number (1) Set Point Source of the Alarm

Pressure

Low Oil Pressure 142-5916 or 146-9438 Block 1

105 kPa (15 psi) @LS

260 kPa (38) @HS Low Speed Oil Contactor or High Speed Oil Contactor, or the Lube Oil Filter Outlet Pressure Transducer

High Crankcase Pressure 147-2369 In-line 142-5919 Vee

1 kPa (.15 psi) Crankcase pressure contactor

Temperature

High Jacket Water Outlet Temperature 142-5916 or 146-9438 Block 4

109 °C (228 °F) Jacket Water Contactor or Optional Transducer

Miscellaneous

Oil Mist Detector Various Contact Closure Oil Mist Detector - Not in all engines

Overspeed 146-5522, 146-5523, 146-5524, 146-5525 113% of Rated Speed Engine Speed Switch and MMS

Metal Particle Detection Basic Engine Metal Particles in Oil Plus 5 Seconds Metal Particle Detector

( 1 ) The group part numbers are provided for reference only. For individual part numbers see Reference Information, "Reference Parts Information".Low Speed - The engine speed is below 75% of the rated engine speed.High Speed - The engine speed is above 75% of the rated engine speed.The "Sensor Failure Alarm" Screen

The "Sensor Failure Alarm" screen is displayed when unexpected signals are received by the PLC. The alarm monitors sensors which can produce alarms or shutdowns.

Table 3

Sensor Failure Alarms for the Marine Monitoring System

Description Sensor Location

Group Part Number (1) Set Point Source of the Alarm

RTD/PT 100 Failures Various

< -50 °C (-58 °F) or

> 150 °C (302 °F) Lube oil, After Cooler/Oil Cooler, Jacket Water, and Inlet Manifold Temperatures

Thermocouples Various

< -50 °C (-58 °F) or

> 700 °C (1292 °F) Individual Cylinder, Pre-Turbine, and Stack Thermocouples

4-20mA Transducers Various < 3.5 mA or > 20.15 mA Engine Speed Transducer, Lube Oil and Fuel pressure transducers

Contactors Various No signal

A shutdown secures the fuel and a shutdown secures the air to the engine. A fuel shutoff solenoid may be located in the fuel actuator. The fuel shutoff solenoid is energized. The injector is driven to the off position. This secures the fuel.The air shutoff solenoid secures the air. When this solenoid is activated compressed air flows to the air damper. The air releases a pin. When the pin is released, a spring closes the air damper. This secures the combustion air supply from the turbochargers to the aftercooler.Note: The air damper must be MANUALLY reset before the engine can be restarted. The Marine Engine Control Panel must also be reset with the "RESET" switch before the MMS will allow starting. The panel may not be reset until the engine has stopped rotating. Determine the cause of the shutdown and correct the problem prior to engine operation.

Table 2

Shutdowns of the Marine Monitoring System

Description Sensor Location

Group Part Number (1) Set Point Source of the Alarm

Pressure

Low Oil Pressure 142-5916 or 146-9438 Block 1

105 kPa (15 psi) @LS

260 kPa (38) @HS Low Speed Oil Contactor or High Speed Oil Contactor, or the Lube Oil Filter Outlet Pressure Transducer

High Crankcase Pressure 147-2369 In-line 142-5919 Vee

1 kPa (.15 psi) Crankcase pressure contactor

Temperature

High Jacket Water Outlet Temperature 142-5916 or 146-9438 Block 4

109 °C (228 °F) Jacket Water Contactor or Optional Transducer

Miscellaneous

Oil Mist Detector Various Contact Closure Oil Mist Detector - Not in all engines

Overspeed 146-5522, 146-5523, 146-5524, 146-5525 113% of Rated Speed Engine Speed Switch and MMS

Metal Particle Detection Basic Engine Metal Particles in Oil Plus 5 Seconds Metal Particle Detector

( 1 ) The group part numbers are provided for reference only. For individual part numbers see Reference Information, "Reference Parts Information".Low Speed - The engine speed is below 75% of the rated engine speed.High Speed - The engine speed is above 75% of the rated engine speed.The "Sensor Failure Alarm" Screen

The "Sensor Failure Alarm" screen is displayed when unexpected signals are received by the PLC. The alarm monitors sensors which can produce alarms or shutdowns.

Table 3

Sensor Failure Alarms for the Marine Monitoring System

Description Sensor Location

Group Part Number (1) Set Point Source of the Alarm

RTD/PT 100 Failures Various

< -50 °C (-58 °F) or

> 150 °C (302 °F) Lube oil, After Cooler/Oil Cooler, Jacket Water, and Inlet Manifold Temperatures

Thermocouples Various

< -50 °C (-58 °F) or

> 700 °C (1292 °F) Individual Cylinder, Pre-Turbine, and Stack Thermocouples

4-20mA Transducers Various < 3.5 mA or > 20.15 mA Engine Speed Transducer, Lube Oil and Fuel pressure transducers

Contactors Various No signal