Information injection-pump assembly

ZEXEL

106691-2051

1066912051

MITSUBISHI

ME050831

me050831

Rating:

Service parts 106691-2051 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME059740

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

106691-2051

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106691-2051

1066912051

MITSUBISHI

ME050831

me050831

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.9

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

157.5

154.5

160.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

4+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.9

8.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

B

Rack position

4.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

12.7

10.8

14.6

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

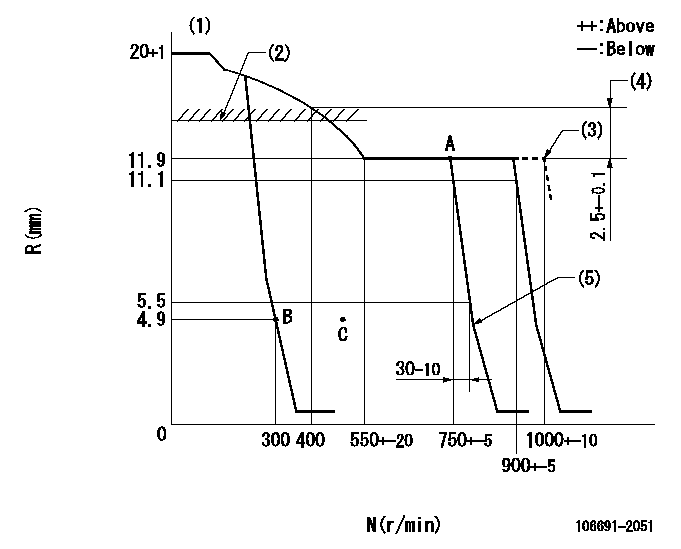

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)At shipping

(4)Rack difference between N = N1 and N = N2

(5)Idle sub spring setting: L1.

----------

K=8 RAL=12.2+0.2mm N1=750r/min N2=400r/min L1=4.6+-0.1mm

----------

----------

K=8 RAL=12.2+0.2mm N1=750r/min N2=400r/min L1=4.6+-0.1mm

----------

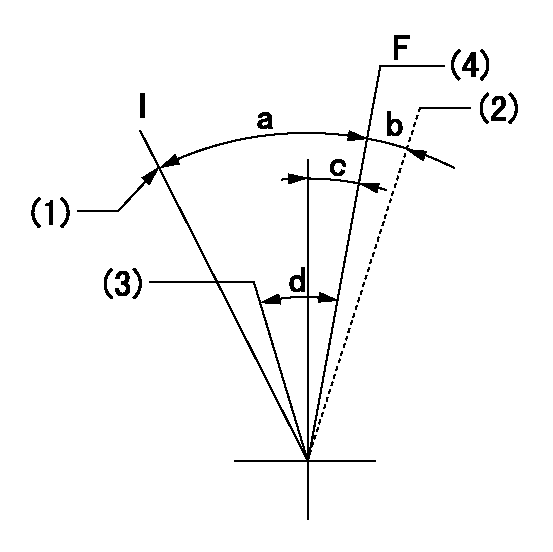

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=750r/min bb=900r/min

----------

a=26deg+-5deg b=(5deg) c=2deg+-5deg d=6deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=26deg+-5deg b=(5deg) c=2deg+-5deg d=6deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Cooling System Diagram

Illustration 18 g00594718

Touch the icon for the cooling system on the navigation bar in order to view the window. The window displays the cooling system parameters. The window also displays a system diagram.Touch the gauge in the upper right hand corner in order to see a real time data for the cooling system.Real Time Data for the Cooling System

Illustration 19 g00562789

"Cooling System" Screen

Illustration 20 g00562791

SymbolsTouch the gauge in the upper right hand corner in order to see a real time data for the cooling system. The window has gauges and a trend chart in real time. An hour of real time data is displayed.Touch the gauge in order to see the trends. The trend chart only shows one parameter at one time.Touch the after cooler and oil cooler water inlet temperature gauge in order to see the trend on the graph.Touch the icon in the upper right corner of the window in order to return to the cooling system diagram.The critical limits are shown with a yellow mark on the gauge. Engine shutdown conditions are shown with a red mark on the gauge.Exhaust

Exhaust Port Temperatures

Illustration 21 g00562793

Touch the exhaust icon on the navigation bar in order to view the window for the exhaust port temperature. The exhaust port temperatures are represented by a bar graph. The actual exhaust temperature is shown with a blue mark. The normal operating temperature range for each port is shown with a green mark. The variation of the critical limits are shown with yellow marks. The critical limit is shown with a yellow mark. The average port temperature is shown with a purple mark. Touch the "Deviation" button in order to view the exhaust port temperature deviation.Touch the trend icon in order to view the stack temperatures and the manifold temperatures as well as trends in real time. Exhaust Port Temperature Deviation

Illustration 22 g00562798

Touch the "Deviation" button on the "Exhaust Port Temperatures" window in order to view the Exhaust Port Temperature Deviation. The window shows the deviation from the average for each port temperature. The yellow marks are the maximum temperature deviation. This is the deviation that is allowed above the average temperature and below the average temperature.Touch the button with the arrows and the bar graph in order to return to the "Exhaust Port Temperatures" window.Exhaust Stack and Manifold

Illustration 23 g00562800

Touch the trend icon on the "Exhaust Port Temperatures" window in order to view the "Exhaust Manifold and Stack Temperatures" window. The actual exhaust manifold temperature and stack temperature will be a blue color. The variation of the normal operating temperature for the exhaust manifold and the stack temperature is shown as a green color. The variation of the critical limits are shown with yellow marks. The critical limit is shown with a yellow mark. The average port temperature is shown with a purple mark. Touch the trends icon in order to view the stack temperatures and manifold temperatures. This button also shows trends in real time.Touch the arrow icon in order to return to the

Illustration 18 g00594718

Touch the icon for the cooling system on the navigation bar in order to view the window. The window displays the cooling system parameters. The window also displays a system diagram.Touch the gauge in the upper right hand corner in order to see a real time data for the cooling system.Real Time Data for the Cooling System

Illustration 19 g00562789

"Cooling System" Screen

Illustration 20 g00562791

SymbolsTouch the gauge in the upper right hand corner in order to see a real time data for the cooling system. The window has gauges and a trend chart in real time. An hour of real time data is displayed.Touch the gauge in order to see the trends. The trend chart only shows one parameter at one time.Touch the after cooler and oil cooler water inlet temperature gauge in order to see the trend on the graph.Touch the icon in the upper right corner of the window in order to return to the cooling system diagram.The critical limits are shown with a yellow mark on the gauge. Engine shutdown conditions are shown with a red mark on the gauge.Exhaust

Exhaust Port Temperatures

Illustration 21 g00562793

Touch the exhaust icon on the navigation bar in order to view the window for the exhaust port temperature. The exhaust port temperatures are represented by a bar graph. The actual exhaust temperature is shown with a blue mark. The normal operating temperature range for each port is shown with a green mark. The variation of the critical limits are shown with yellow marks. The critical limit is shown with a yellow mark. The average port temperature is shown with a purple mark. Touch the "Deviation" button in order to view the exhaust port temperature deviation.Touch the trend icon in order to view the stack temperatures and the manifold temperatures as well as trends in real time. Exhaust Port Temperature Deviation

Illustration 22 g00562798

Touch the "Deviation" button on the "Exhaust Port Temperatures" window in order to view the Exhaust Port Temperature Deviation. The window shows the deviation from the average for each port temperature. The yellow marks are the maximum temperature deviation. This is the deviation that is allowed above the average temperature and below the average temperature.Touch the button with the arrows and the bar graph in order to return to the "Exhaust Port Temperatures" window.Exhaust Stack and Manifold

Illustration 23 g00562800

Touch the trend icon on the "Exhaust Port Temperatures" window in order to view the "Exhaust Manifold and Stack Temperatures" window. The actual exhaust manifold temperature and stack temperature will be a blue color. The variation of the normal operating temperature for the exhaust manifold and the stack temperature is shown as a green color. The variation of the critical limits are shown with yellow marks. The critical limit is shown with a yellow mark. The average port temperature is shown with a purple mark. Touch the trends icon in order to view the stack temperatures and manifold temperatures. This button also shows trends in real time.Touch the arrow icon in order to return to the