Information injection-pump assembly

BOSCH

9 400 617 776

9400617776

ZEXEL

106691-2041

1066912041

MITSUBISHI

ME050804

me050804

Rating:

Cross reference number

BOSCH

9 400 617 776

9400617776

ZEXEL

106691-2041

1066912041

MITSUBISHI

ME050804

me050804

Zexel num

Bosch num

Firm num

Name

106691-2041

9 400 617 776

ME050804 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22TC * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22TC * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

132.3

129.3

135.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

4+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.9

8.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

4.9+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

12.7

10.8

14.6

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

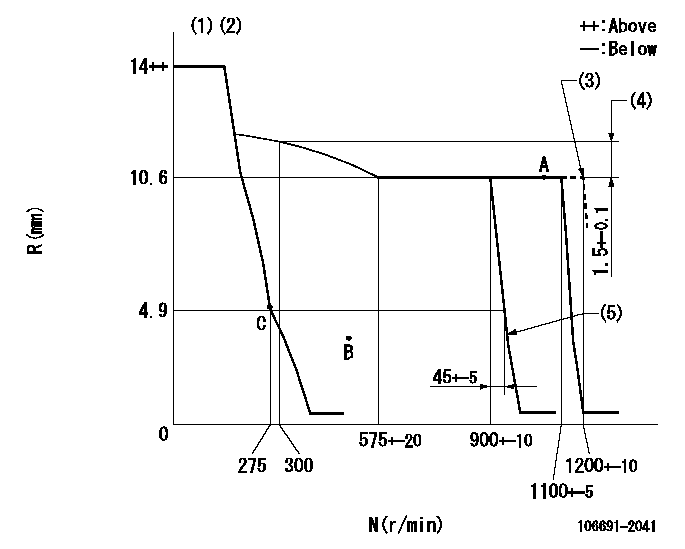

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

(3)At shipping

(4)Rack difference between N = N1 and N = N2

(5)Idle sub spring setting: L1.

----------

K=12 N1=1100r/min N2=300r/min L1=3.5+-0.1mm

----------

----------

K=12 N1=1100r/min N2=300r/min L1=3.5+-0.1mm

----------

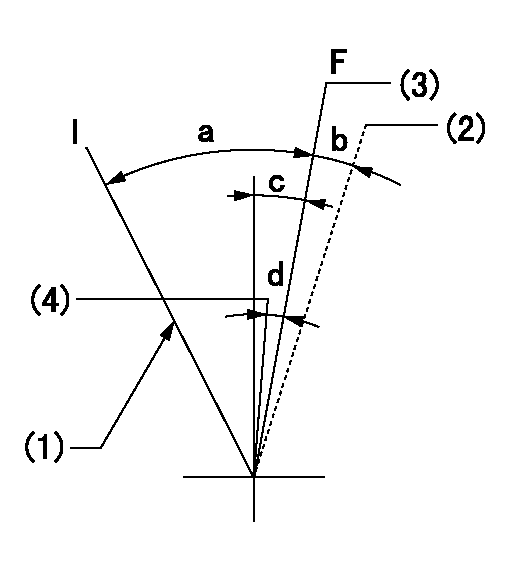

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Set the pump speed at aa

(4)Set the pump speed at bb.

----------

aa=1100r/min bb=900r/min

----------

a=32deg+-5deg b=(5deg) c=9deg+-5deg d=8deg+-5deg

----------

aa=1100r/min bb=900r/min

----------

a=32deg+-5deg b=(5deg) c=9deg+-5deg d=8deg+-5deg

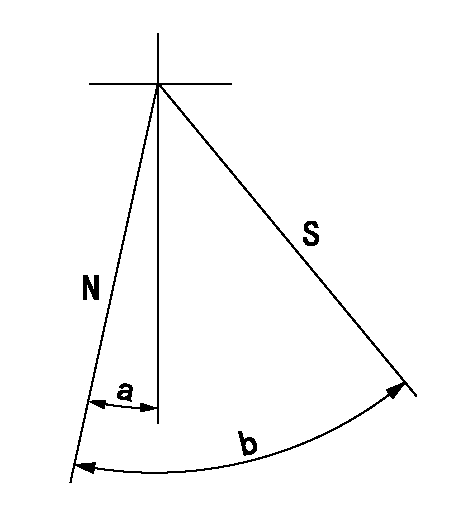

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Problem 2

The engine does not crank.

Check the engine mounted start switch (EMSS).

Ensure that the emergency stop switch (ES) has been reset.

Place a switch across the terminals of the EMSS.

Close the switch momentarily, but do not start the engine.

Remove the switch when the test is completed. Result

The engine cranks.The EMSS is faulty or the circuit breaker (CB2) must be reset.

The engine does not crank.Go to Step 3.

Check the start/stop switch.

Ensure that the emergency stop switch (ES) has been reset.

Connect a switch with a 2 amp capacity between terminals (TS-21) and (TS-26) of the junction box.

Close the switch momentarily, but do not start the engine.

Disconnect the switch after the test is completed. Results

The engine cranks.The start/stop switch is faulty or the wiring to the switch is faulty. Replace the switch or repair the wiring. The circuit breaker (CB2) may need to be reset.

The engine does not crank.Go to Step 3.

Check the emergency stop switch (ES).

Ensure that the emergency stop switch (ES) has been reset.

Connect a switch with a 2 amp capacity between terminals (TS-26) and (TS-24) of the junction box.

Close the switch momentarily but do not start the engine.

Disconnect the switch after the test is completed. Result

The engine cranks.The emergency stop switch (ES) is faulty.

The engine does not crank.Reset the circuit breaker (CB5) and repeat Step 3. If the engine does not crank go to Step 4.

Check the components of the starting system.

Check the voltage at terminal (TS-24) of the junction box. Result

The voltage is low. Low voltage is between 1 volt and 20 volts.Charge the battery or repair the loose connections between the battery cable terminal and the battery. STOP.

The voltage is above 20 volts.The magnetic switch (MS), the pinion solenoid (PS), or the starting motor (SM) is faulty. The circuit breaker (CB2) may need to be reset. Reset the circuit breaker and repair the component that is faulty.

The voltage is zero (less than 1 volt).The circuit breaker (CB5) is being overloaded or the circuit breaker is faulty. Repair the short circuit or replace the circuit breaker. STOP.Problem 3

The engine starts and shutdown occurs immediately, or engine cranking terminates.

Check the protection switches.

Measure the voltage at terminal (SR2-30) while you crank the engine. Result

The voltage is above 10 volts while you crank the engine. The voltage then decreases to zero when the engine shuts down.The emergency stop switch (ES), the water temperature contactor switch (WTS), and the start/stop switch are opening. Check the start/stop switch first. The switch may be open across the common pair of contacts for the START/RUN switch when the switch is in the START position. The switch may also be open when the switch is released from the START position. Go to Step 7 of "Problem 1".

The voltage is above 10 volts at all times.The diode (D2) is faulty or there is a short across the diode circuit. The engine oil pressure switch (OPS1) may also have an intermittent short in the switch or in the connection. Refer

The engine does not crank.

Check the engine mounted start switch (EMSS).

Ensure that the emergency stop switch (ES) has been reset.

Place a switch across the terminals of the EMSS.

Close the switch momentarily, but do not start the engine.

Remove the switch when the test is completed. Result

The engine cranks.The EMSS is faulty or the circuit breaker (CB2) must be reset.

The engine does not crank.Go to Step 3.

Check the start/stop switch.

Ensure that the emergency stop switch (ES) has been reset.

Connect a switch with a 2 amp capacity between terminals (TS-21) and (TS-26) of the junction box.

Close the switch momentarily, but do not start the engine.

Disconnect the switch after the test is completed. Results

The engine cranks.The start/stop switch is faulty or the wiring to the switch is faulty. Replace the switch or repair the wiring. The circuit breaker (CB2) may need to be reset.

The engine does not crank.Go to Step 3.

Check the emergency stop switch (ES).

Ensure that the emergency stop switch (ES) has been reset.

Connect a switch with a 2 amp capacity between terminals (TS-26) and (TS-24) of the junction box.

Close the switch momentarily but do not start the engine.

Disconnect the switch after the test is completed. Result

The engine cranks.The emergency stop switch (ES) is faulty.

The engine does not crank.Reset the circuit breaker (CB5) and repeat Step 3. If the engine does not crank go to Step 4.

Check the components of the starting system.

Check the voltage at terminal (TS-24) of the junction box. Result

The voltage is low. Low voltage is between 1 volt and 20 volts.Charge the battery or repair the loose connections between the battery cable terminal and the battery. STOP.

The voltage is above 20 volts.The magnetic switch (MS), the pinion solenoid (PS), or the starting motor (SM) is faulty. The circuit breaker (CB2) may need to be reset. Reset the circuit breaker and repair the component that is faulty.

The voltage is zero (less than 1 volt).The circuit breaker (CB5) is being overloaded or the circuit breaker is faulty. Repair the short circuit or replace the circuit breaker. STOP.Problem 3

The engine starts and shutdown occurs immediately, or engine cranking terminates.

Check the protection switches.

Measure the voltage at terminal (SR2-30) while you crank the engine. Result

The voltage is above 10 volts while you crank the engine. The voltage then decreases to zero when the engine shuts down.The emergency stop switch (ES), the water temperature contactor switch (WTS), and the start/stop switch are opening. Check the start/stop switch first. The switch may be open across the common pair of contacts for the START/RUN switch when the switch is in the START position. The switch may also be open when the switch is released from the START position. Go to Step 7 of "Problem 1".

The voltage is above 10 volts at all times.The diode (D2) is faulty or there is a short across the diode circuit. The engine oil pressure switch (OPS1) may also have an intermittent short in the switch or in the connection. Refer

Have questions with 106691-2041?

Group cross 106691-2041 ZEXEL

Mitsubishi

106691-2041

9 400 617 776

ME050804

INJECTION-PUMP ASSEMBLY

6D22TC

6D22TC