Information injection-pump assembly

ZEXEL

106691-2021

1066912021

MITSUBISHI

ME059749

me059749

Rating:

Service parts 106691-2021 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056329

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)/21.6(220)

15.

NOZZLE SET

Include in #1:

106691-2021

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106691-2021

1066912021

MITSUBISHI

ME059749

me059749

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.9

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

157.5

154.5

160.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

4+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.9

8.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

B

Rack position

4.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

12.7

10.8

14.6

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

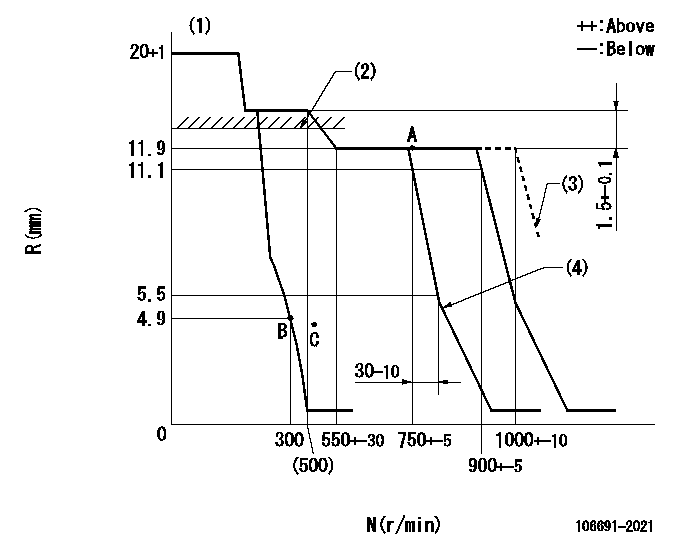

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)At shipping

(4)Idle sub spring setting: L1.

----------

K=12 RAL=12.2+0.2mm L1=4.6+-0.1mm

----------

----------

K=12 RAL=12.2+0.2mm L1=4.6+-0.1mm

----------

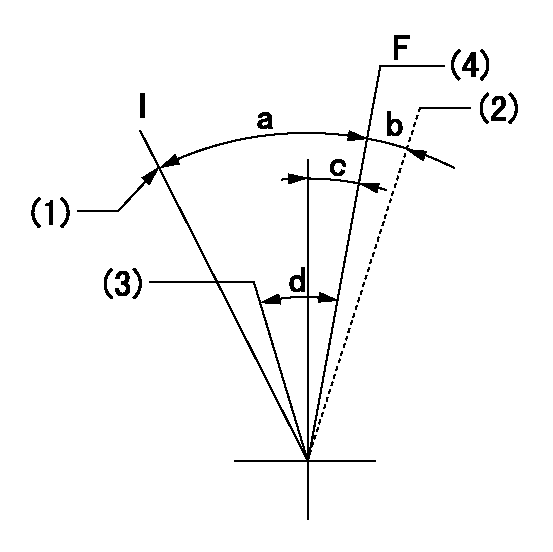

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=750r/min bb=900r/min

----------

a=26deg+-5deg b=(5deg) c=2deg+-5deg d=6deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=26deg+-5deg b=(5deg) c=2deg+-5deg d=6deg+-5deg

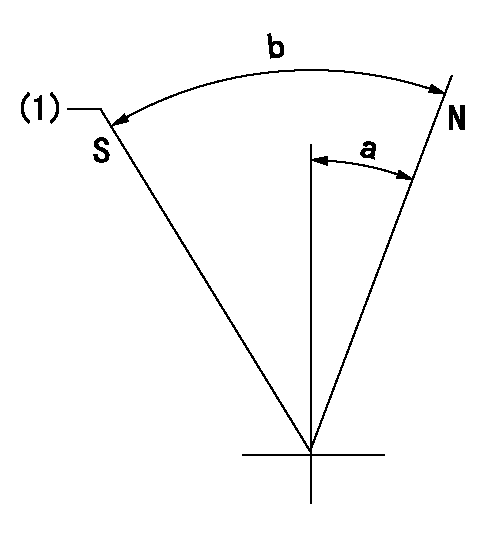

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=39deg+-5deg b=53deg+-5deg

----------

----------

a=39deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Replacing a Power Supply

Disconnect the power supply.

To avoid damage to electronic components, do not remove the processor from the SLC 5/04 Chassis until all power is removed from the power supply.Do not expose memory modules to surfaces or areas that may typically hold an electrostatic charge.

Remove the two retaining screws that secure the power supply to the chassis.

Remove the power supply from the chassis.

To avoid potential damage to the processor, handle all modules by the ends of the carrier or edges of the plastic housing. Skin oil or dirt can corrode metallic surfaces, inhibiting electrical contact.

Align the new power supply and the guides in the chassis.

Gently slide the power supply in the chassis. Secure the top retainer clips and secure the bottom retainer clips.

Install the two retaining screws that secure the power supply to the chassis.

Install a wire tie in order to secure your wiring.

Cover any unused slots. This protects the chassis.

Illustration 1 g00563308

Verify that the new power supply corrects the problem.

Disconnect the power supply.

To avoid damage to electronic components, do not remove the processor from the SLC 5/04 Chassis until all power is removed from the power supply.Do not expose memory modules to surfaces or areas that may typically hold an electrostatic charge.

Remove the two retaining screws that secure the power supply to the chassis.

Remove the power supply from the chassis.

To avoid potential damage to the processor, handle all modules by the ends of the carrier or edges of the plastic housing. Skin oil or dirt can corrode metallic surfaces, inhibiting electrical contact.

Align the new power supply and the guides in the chassis.

Gently slide the power supply in the chassis. Secure the top retainer clips and secure the bottom retainer clips.

Install the two retaining screws that secure the power supply to the chassis.

Install a wire tie in order to secure your wiring.

Cover any unused slots. This protects the chassis.

Illustration 1 g00563308

Verify that the new power supply corrects the problem.