Information injection-pump assembly

BOSCH

9 400 617 774

9400617774

ZEXEL

106691-2001

1066912001

MITSUBISHI

ME059724

me059724

Rating:

Service parts 106691-2001 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

106691-2001

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 774

9400617774

ZEXEL

106691-2001

1066912001

MITSUBISHI

ME059724

me059724

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.9

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

157.5

154.5

160.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

4+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.9

8.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

B

Rack position

4.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

12.7

10.8

14.6

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

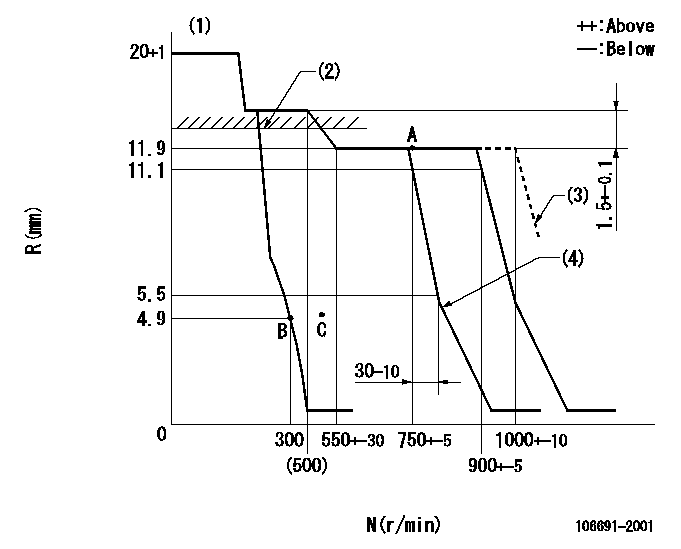

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)At shipping

(4)Idle sub spring setting: L1.

----------

K=12 RAL=12.2+0.2mm L1=4.6+-0.1mm

----------

----------

K=12 RAL=12.2+0.2mm L1=4.6+-0.1mm

----------

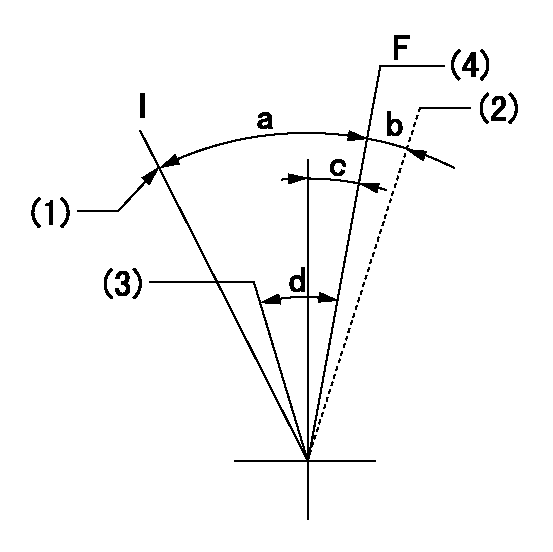

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=750r/min bb=900r/min

----------

a=26deg+-5deg b=(5deg) c=2deg+-5deg d=6deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=26deg+-5deg b=(5deg) c=2deg+-5deg d=6deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Depending on application severity and localized environmental conditions, and also depending on maintenance practices, operating Direct Injection (DI) diesel engines and operating PC (Precombustion Chamber) diesel engines on fuel with sulfur levels over 0.1 percent (1000 ppm) may require significantly shortened oil change intervals in order to help maintain adequate wear protection. Refer to this Special Publication, "Fuel Specifications" section, “Diesel Fuel Sulfur” topic for additional information.

Note: Do NOT use only this Special Publication as a basis for determining oil drain intervals.This Special Publication does not address recommended oil drain intervals, but rather provides guidance that should be used with your specific engine/machine Operation and Maintenance Manuals in determining acceptable oil drain intervals. Consult your engine/machine Operation and Maintenance Manuals, and consult your Cat dealer for additional guidance, including but not limited to guidance on establishing optimized and/or acceptable oil drain intervals.Total Base Number (TBN) and Fuel Sulfur Levels for Engines That Use Heavy Fuel Oil (HFO)

Note: Only specially configured 3600 diesel engines can use HFO.The use of Cat S O S Services oil analysis is recommended for determining oil life.TBN is also commonly referred to as Base Number (BN).Generally, lubrication oils for engines that use heavy fuel oil are available with a TBN in a range of 20 to 50 ("ASTM D2896"). Oil companies list these oils that have a high TBN as oils for “trunk piston” or “medium speed marine” diesel engines. Most of the Caterpillar experience is with the oils that have a TBN of 30 or 40. The TBN for a new oil depends on the fuel sulfur level. The TBN for a new oil depends on the fuel sulfur level. For 3600 Series engines that use heavy fuel oil, the minimum new oil TBN must be 20 as determined by the "ASTM D2896" procedure.Engine oils of high TBN can neutralize the sulfur in the fuel and allow for long drain interval. However, oils with a high TBN and/or high ash can produce excessive deposits on the pistons and valves. These deposits can lead to the following results:

A loss of stable oil control

Polishing of the cylinder bore

Guttering of the valvesHigh quality engine oils that are formulated for operation using HFO are balanced to allow the desired oil drain intervals while protecting engines from excessive deposits. The oil must also have the proof of performance that is explained in the Selecting a Commercial Oil article.Use the following guidelines for fuel sulfur levels that exceed 2.0 percent:

Choose an oil with the highest TBN that meets the Caterpillar performance requirements.

Base the oil change interval on the oil analysis. Ensure that the oil analysis includes the condition of the oil, TBN, and a wear metal analysis. Reduce the oil change interval, if necessary.TBN testing is an optional part of the S O S Services oil analysis program. TBN testing may be done in addition to the standard S O S Services tests for oil deterioration. In most applications, the S O S Services tests for oxidation, sulfation, viscosity,