Information injection-pump assembly

BOSCH

9 400 617 773

9400617773

ZEXEL

106691-1971

1066911971

ISUZU

1156007350

1156007350

Rating:

Cross reference number

BOSCH

9 400 617 773

9400617773

ZEXEL

106691-1971

1066911971

ISUZU

1156007350

1156007350

Zexel num

Bosch num

Firm num

Name

106691-1971

9 400 617 773

1156007350 ISUZU

INJECTION-PUMP ASSEMBLY

E120 * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

E120 * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

112.9

109.1

116.7

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.6

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

110.2

106.4

114

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.1

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

102.8

98.8

106.8

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.5+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

22.5

19.3

25.7

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set so that the point C's injection quantity is obtained. Is not effective when C's rack position R = R1.

----------

K=10 R1=7.5mm

----------

----------

K=10 R1=7.5mm

----------

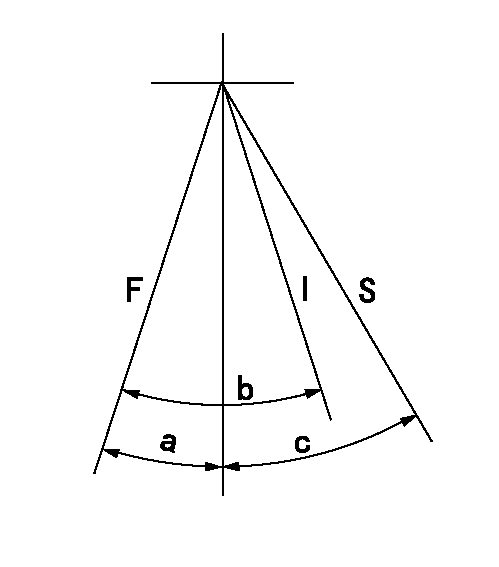

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=8deg+-5deg b=23deg+-5deg c=32deg+-3deg

----------

----------

a=8deg+-5deg b=23deg+-5deg c=32deg+-3deg

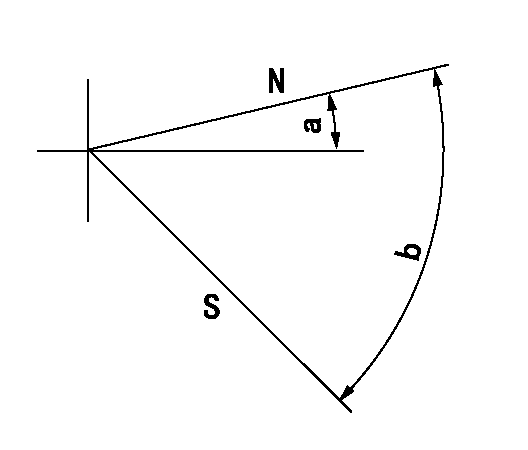

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(10deg) b=(53deg)

----------

----------

a=(10deg) b=(53deg)

Information:

Illustration 1 g00562591

Marine Engine Control Panel

The Marine Engine Control Panel contains the following components:

A personal computer (PC) that displays the operating information

A minimum protection backup relay system

Control switches for starting the engine

Control switches for stopping the engine

The engine speed switch

A Programmable Logic ControllerPersonal Computer

The PC display provides the engine status for the operator.Control Switches

The following controls are located on the Marine Engine Control Panel:

"EMERGENCY STOP" button

"OFF/RESET-LOCAL-REMOTE" switch

"PRELUBE-RUN-START" switch

"FUEL CONTROL" switch

"HORN SILENCE-LAMP TEST" switchThe control switch on the Marine Engine Control Panel permits local control of the engine or remote control of the engine. This switch can also be placed in the OFF/RESET position. The "FUEL CONTROL" switch can be placed in the OFF position or the ON position.Weight of the Marine Monitoring System

Each of the following part numbers have a combined weight of 90 kg (198 lb):

146-5522 EMCP Electronic Control

146-5523 EMCP Electronic Control

146-5524 EMCP Electronic Control

146-5525 EMCP Electronic Control The 147-5676 Instrument Panel Mounting has a weight of 86 kg (190 lb).Programmable Logic Controller

The programmable logic controller provides complete monitoring and control for a Caterpillar 3600 Engine. The basic modular programmable logic controller consists of the following components:

Power Supply

Central Processing Unit Module (CPU)

Chassis

Input Modules

Output Modules

Engine Speed SwitchThe programmable logic controller is the computer that conducts the following engine functions:

Control

Monitor

ProtectionThe CPU in the programmable logic controller contains the software that controls programmable logic controller behavior.The following components are used as engine sensors: contactors, thermocouples, resistance temperature detectors (RTDS) and transducers.Power Supply

The power supply delivers 24 VDC for the following components: the CPU, the chassis, the control panel, the input modules and the output modules. The 24 VDC is typically provided by a battery set.Central Processing Unit Module

The operator can configure the memory. The operator can configure the memory for data. The operator can also configure the memory for the storage of programs. The memory size is adjustable from 1K to 64K. The CPU is supported by a variety of modules. These modules include digital modules, analog modules, and smart modules. The CPU is seated in slot 0 of the programmable logic controller chassis.Discrete Input Modules

The discrete input modules are in the following list:

Thermocouple Module

RTD Input Module

Digital Modules

Analog ModulesWhen you apply a voltage to the channel, the relay is energized. An energized input closes all of the contacts that are normally open. An energized input will open all of the contacts that are normally closed. Digital modules are used to determine whether a circuit is ON/OFF. A number of modules are available. The MMS modules have sixteen channels.Discrete Output Modules

The programmable logic controller discrete output modules consist of analog modules and digital modules. Voltage control is provided by the output modules. A module provides power for the following list of functions: energizing the lamps, energizing the relays, energizing the fuel shutoff solenoid and energizing the air shutoff solenoid.Engine Speed Switch

The speed switch accepts a signal from the magnetic pickup. The magnetic pickup is mounted on the engine. The speed switch determines the engine speed from the signal. The speed switch provides

Have questions with 106691-1971?

Group cross 106691-1971 ZEXEL

Isuzu

106691-1971

9 400 617 773

1156007350

INJECTION-PUMP ASSEMBLY

E120

E120