Information injection-pump assembly

ZEXEL

106691-0201

1066910201

Rating:

Cross reference number

ZEXEL

106691-0201

1066910201

Zexel num

Bosch num

Firm num

Name

106691-0201

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-1720

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

132424-0620

Overflow valve opening pressure (governor side)

kPa

157

123

191

Overflow valve opening pressure (governor side)

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.1

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

162

160

164

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.8+-0.

5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

162.2

159.2

165.2

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_03

Adjusting point

C

Rack position

6+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

13.2

12.2

14.2

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

R1(9.5)

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

112

109

115

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_05

Adjusting point

F

Rack position

R1+0.5++

Pump speed

r/min

40

40

40

Average injection quantity

mm3/st.

110

110

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R1(9.5)

Boost pressure

kPa

6.7

4

6.7

Boost pressure

mmHg

50

30

50

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

11.7

Boost pressure

kPa

24

Boost pressure

mmHg

180

Timer adjustment

Pump speed

r/min

200+100

Advance angle

deg.

1.6

1.1

2.1

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500-150

Advance angle

deg.

0

0

0

Timer adjustment_03

Pump speed

r/min

910+80

Advance angle

deg.

0

0

0

Timer adjustment_04

Pump speed

r/min

(1050)

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

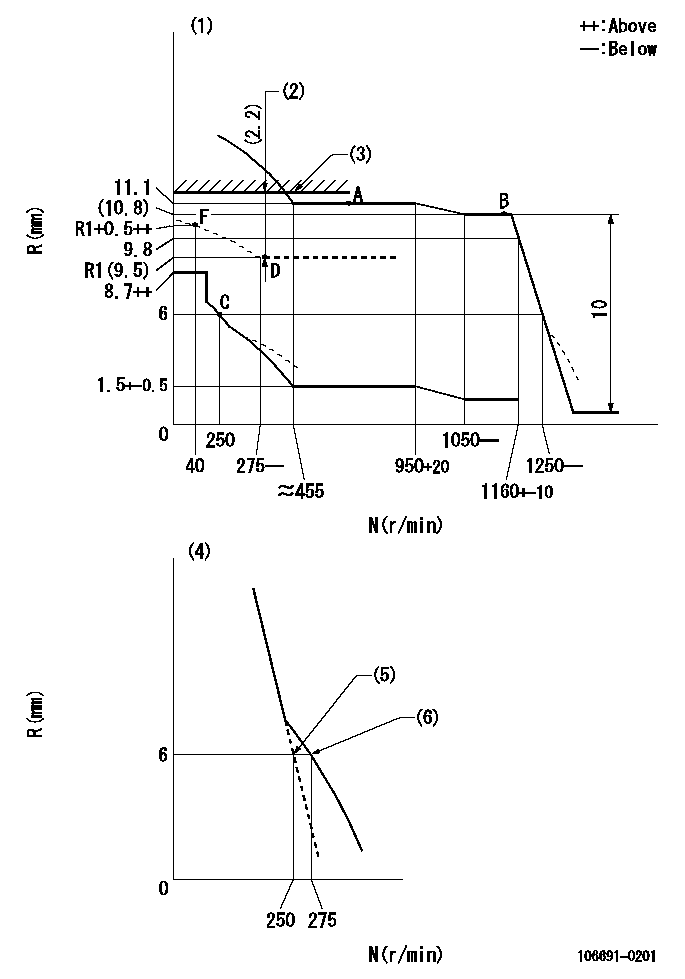

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Damper spring setting: DL

(2)Boost compensator stroke

(3)Rack limit using the stop lever: R1

(4)Variable speed specification.

(5)Main spring setting

(6)Set idle sub-spring

----------

DL=5-0.2mm R1=11.7+-0.1mm

----------

----------

DL=5-0.2mm R1=11.7+-0.1mm

----------

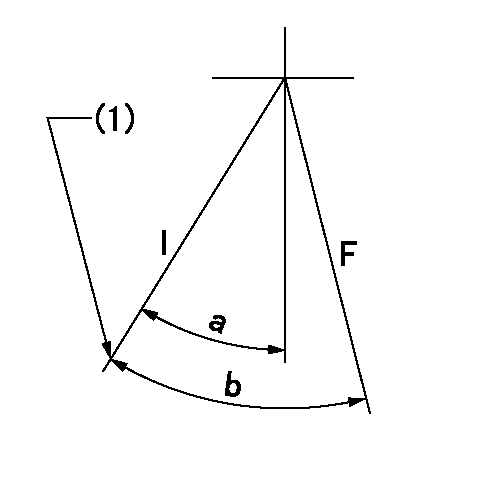

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=26deg+-5deg

----------

----------

a=10deg+-5deg b=26deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=20.5deg+-5deg b=35deg+-3deg

----------

----------

a=20.5deg+-5deg b=35deg+-3deg

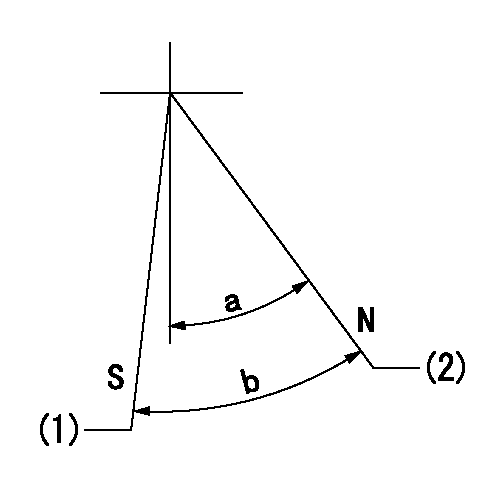

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb.

(2)Rack position = cc

----------

aa=1+0.5mm bb=0r/min cc=11.7mm

----------

a=28deg+-5deg b=30deg+-3deg

----------

aa=1+0.5mm bb=0r/min cc=11.7mm

----------

a=28deg+-5deg b=30deg+-3deg

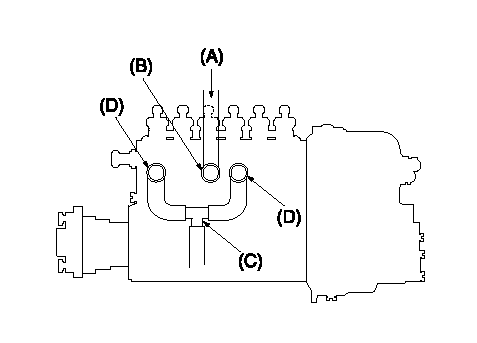

0000001501 Q ADJUSTMENT PIPING

Tester fuel pipe A

Fuel inlet B

(C) Forked piping

(D) Overflow valve

Piping at standard injection quantity adjustment

1. Because the pump gallery is divided into two, be careful of the fuel piping at adjustment.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Start By:a. remove cylinder head assemblyb. remove oil panc. remove piston cooling jets 1. Remove two rod cap bolts (1) from each rod. Remove rod caps (2).2. Using a soft jawed hammer, tap rod (3) away from the crankshaft. Remove bearing half (4).

When removing the cylinder pack, watch the rod, and prevent it from catching on the bore in the cylinder block as it comes out.

3. Install tooling (A), and remove cylinder pack (5). 4. Remove cylinder liner seal (6) at the base of the spacer block.5. Remove the remainder of tooling (A) from cylinder pack (5). 6. Remove the rod and piston from the cylinder liner. Remove seal (7) from the cylinder liner. The following steps are for the installation of the cylinder pack.7. Install a new cylinder liner seal (6) in the base of the spacer block. Lubricate the seal with clean engine oil. Some engines use pistons which have the word "FRONT" stamped on the crown of the piston. Be sure the word "FRONT" is toward the front of the engine when the piston is installed. The etched number on the connecting rod must be on the right side and must be installed in the corresponding cylinder. 9U-5839 Liquid Gasket Material is applied to the cylinder liners in the area shown in the illustration. The liquid gasket material helps prevent oil leaks from between the cylinder block and spacer block. DO NOT apply any 9U-5839 Liquid Gasket Material between the engine spacer block and the cylinder block surfaces. Using excessive amounts of liquid gasket material on the liner flange seat can cause oil leaks due to distortion of the O-ring seals between the spacer block and cylinder block.8. Install a new seal (7) on the cylinder liner.9. Lubricate the lower portion of the cylinder liner with clean engine oil. Be sure the corresponding crankshaft throw is at bottom center. Position cylinder pack (5), and guide rod (3) into place. Use tooling (B), and press cylinder pack (5) into place. Refer to the "Systems Operation Testing And Adjusting" module, Form No. SENR5561, for checking Cylinder Liner Projection.10. With rod (3) in this position, install the upper half of rod bearing (4). Be sure the bearing tab properly engages with the slot in the connecting rod. Lubricate the bearing surface with clean engine oil. Tap the piston down with a soft faced hammer until the rod and bearing contacts the crankshaft.11. With rod cap bearing in place and lubricated, install rod cap (2). Lubricate rod bolts (1) with 2P2506 Thread Lubricant. Install rod bolts (1), and tighten them to a torque of 130 7 N m (95 5 lb ft). Mark each bolt head, and tighten each bolt an additional 1/6 60 5 ( turn).End By:a. install piston cooling jetsb. install oil panc. install cylinder head assembly

When removing the cylinder pack, watch the rod, and prevent it from catching on the bore in the cylinder block as it comes out.

3. Install tooling (A), and remove cylinder pack (5). 4. Remove cylinder liner seal (6) at the base of the spacer block.5. Remove the remainder of tooling (A) from cylinder pack (5). 6. Remove the rod and piston from the cylinder liner. Remove seal (7) from the cylinder liner. The following steps are for the installation of the cylinder pack.7. Install a new cylinder liner seal (6) in the base of the spacer block. Lubricate the seal with clean engine oil. Some engines use pistons which have the word "FRONT" stamped on the crown of the piston. Be sure the word "FRONT" is toward the front of the engine when the piston is installed. The etched number on the connecting rod must be on the right side and must be installed in the corresponding cylinder. 9U-5839 Liquid Gasket Material is applied to the cylinder liners in the area shown in the illustration. The liquid gasket material helps prevent oil leaks from between the cylinder block and spacer block. DO NOT apply any 9U-5839 Liquid Gasket Material between the engine spacer block and the cylinder block surfaces. Using excessive amounts of liquid gasket material on the liner flange seat can cause oil leaks due to distortion of the O-ring seals between the spacer block and cylinder block.8. Install a new seal (7) on the cylinder liner.9. Lubricate the lower portion of the cylinder liner with clean engine oil. Be sure the corresponding crankshaft throw is at bottom center. Position cylinder pack (5), and guide rod (3) into place. Use tooling (B), and press cylinder pack (5) into place. Refer to the "Systems Operation Testing And Adjusting" module, Form No. SENR5561, for checking Cylinder Liner Projection.10. With rod (3) in this position, install the upper half of rod bearing (4). Be sure the bearing tab properly engages with the slot in the connecting rod. Lubricate the bearing surface with clean engine oil. Tap the piston down with a soft faced hammer until the rod and bearing contacts the crankshaft.11. With rod cap bearing in place and lubricated, install rod cap (2). Lubricate rod bolts (1) with 2P2506 Thread Lubricant. Install rod bolts (1), and tighten them to a torque of 130 7 N m (95 5 lb ft). Mark each bolt head, and tighten each bolt an additional 1/6 60 5 ( turn).End By:a. install piston cooling jetsb. install oil panc. install cylinder head assembly

Have questions with 106691-0201?

Group cross 106691-0201 ZEXEL

Nissan-Diesel

106691-0201

INJECTION-PUMP ASSEMBLY