Information injection-pump assembly

BOSCH

9 400 612 762

9400612762

ZEXEL

106689-4090

1066894090

NIIGATA-URAWA

74W47100A

74w47100a

Rating:

Service parts 106689-4090 INJECTION-PUMP ASSEMBLY:

1.

_

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

74W 3227 1A

12.

Open Pre:MPa(Kqf/cm2)

31.4{320}

15.

NOZZLE SET

Include in #1:

106689-4090

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 612 762

9400612762

ZEXEL

106689-4090

1066894090

NIIGATA-URAWA

74W47100A

74w47100a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

14.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

344

339

349

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

30

27

33

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

16.4++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

350

340

360

Fixing the lever

*

Rack limit

*

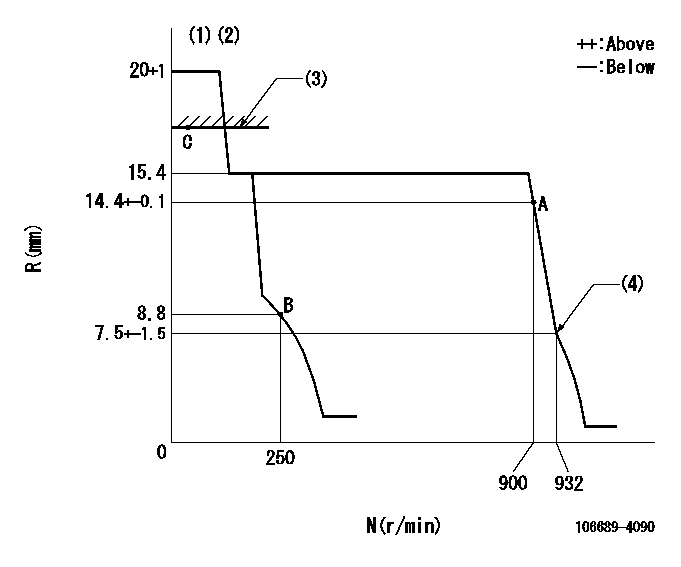

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Idle sub spring setting: L1.

----------

K=20 L1=7.5-0.5mm

----------

----------

K=20 L1=7.5-0.5mm

----------

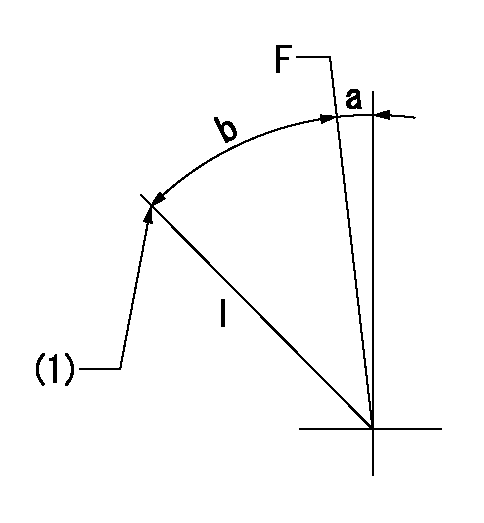

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=1deg+-5deg b=41deg+-5deg

----------

----------

a=1deg+-5deg b=41deg+-5deg

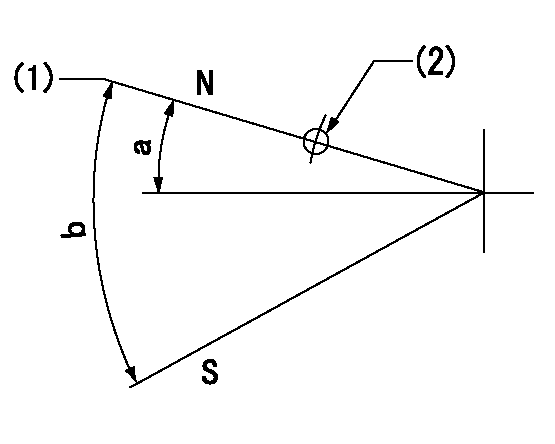

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Use the hole at R = aa

----------

aa=17mm

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=17mm

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(6deg)

----------

----------

a=(6deg)

Information:

Electronic Controls

The electronic controller consists of two main components: the Electronic Control Module (ECM) and the Personality Module. The ECM is the computer which controls the PEEC engine. The Personality Module is the software which controls how the computer behaves. The two must be used together: neither can do anything by itself.Rack Controls

The rack mechanism on a PEEC III engine is very similar to a mechanical 3406B engine. The fuel injection pump is nearly identical; the rack is moved by a servo valve which receives oil pressure from the fuel injection pump. However, the PEEC III servo spool is moved by a solenoid or (BTM) rather than by a linkage controlled by flyweights and springs.PEEC III comes up with a "desired rpm" based on the throttle position, vehicle speed, customer specified parameters, and certain diagnostic codes. The PEEC III governor tries to maintain the desired rpm by sensing actual engine speed using the engine speed sensor, then controlling the rack to achieve the desired rpm. To move the rack, PEEC III adjusts the voltage to the rack solenoid (BTM) to increase rack. More voltage results in more rack. PEEC III knows how far the rack went by reading the rack position sensor. PEEC III increases the voltage to the rack solenoid until it senses the rack is in the desired position. PEEC III sets certain limits on rack motion. "FRC Rack" is a rack limit based on fuel-air ratio control, for emissions purposes. It works similar to a mechanical engine FRC; when PEEC III senses a higher boost pressure (more air into cylinder), it increases the FRC Rack limit, which allows more fuel into the cylinder. "Rated Rack" is a rack limit based on horsepower of the engine. It is similar to the rack stops and torque springs on a mechanical engine. It provides horsepower and torque curves for a specific engine family and rating. All of these limits are programmed by the factory into the personality module.Timing Advance Controls

The timing advance mechanism is the same as the 3406B mechanical engine, except the Timing solenoid (BTM), instead of the flyweights, controls timing advance. PEEC III adjusts voltage to the timing solenoid to change timing advance. More voltage results in more timing advance. PEEC III knows how much advance was achieved by reading the timing position sensor. PEEC III simply increases voltage to the timing solenoid until it senses that the timing advance is in the desired position. Programmable Parameters

Certain parameters that affect PEEC III 3406B Diesel Engine operation may be changed with electronic service tools (either the ECAP or DDT). The parameters are stored in the ECM, and are protected from unauthorized changes by passwords.These parameters are either "System Configuration Parameters" or "Customer Parameters". System Configuration Parameters are those that effect horsepower family or emissions. Customer Parameters are those that affect cruise control, vehicle speed limits, progressive shifting, horsepower rating within a family, and PTO operation.Some parameters may affect engine operation in ways a driver does not expect

The electronic controller consists of two main components: the Electronic Control Module (ECM) and the Personality Module. The ECM is the computer which controls the PEEC engine. The Personality Module is the software which controls how the computer behaves. The two must be used together: neither can do anything by itself.Rack Controls

The rack mechanism on a PEEC III engine is very similar to a mechanical 3406B engine. The fuel injection pump is nearly identical; the rack is moved by a servo valve which receives oil pressure from the fuel injection pump. However, the PEEC III servo spool is moved by a solenoid or (BTM) rather than by a linkage controlled by flyweights and springs.PEEC III comes up with a "desired rpm" based on the throttle position, vehicle speed, customer specified parameters, and certain diagnostic codes. The PEEC III governor tries to maintain the desired rpm by sensing actual engine speed using the engine speed sensor, then controlling the rack to achieve the desired rpm. To move the rack, PEEC III adjusts the voltage to the rack solenoid (BTM) to increase rack. More voltage results in more rack. PEEC III knows how far the rack went by reading the rack position sensor. PEEC III increases the voltage to the rack solenoid until it senses the rack is in the desired position. PEEC III sets certain limits on rack motion. "FRC Rack" is a rack limit based on fuel-air ratio control, for emissions purposes. It works similar to a mechanical engine FRC; when PEEC III senses a higher boost pressure (more air into cylinder), it increases the FRC Rack limit, which allows more fuel into the cylinder. "Rated Rack" is a rack limit based on horsepower of the engine. It is similar to the rack stops and torque springs on a mechanical engine. It provides horsepower and torque curves for a specific engine family and rating. All of these limits are programmed by the factory into the personality module.Timing Advance Controls

The timing advance mechanism is the same as the 3406B mechanical engine, except the Timing solenoid (BTM), instead of the flyweights, controls timing advance. PEEC III adjusts voltage to the timing solenoid to change timing advance. More voltage results in more timing advance. PEEC III knows how much advance was achieved by reading the timing position sensor. PEEC III simply increases voltage to the timing solenoid until it senses that the timing advance is in the desired position. Programmable Parameters

Certain parameters that affect PEEC III 3406B Diesel Engine operation may be changed with electronic service tools (either the ECAP or DDT). The parameters are stored in the ECM, and are protected from unauthorized changes by passwords.These parameters are either "System Configuration Parameters" or "Customer Parameters". System Configuration Parameters are those that effect horsepower family or emissions. Customer Parameters are those that affect cruise control, vehicle speed limits, progressive shifting, horsepower rating within a family, and PTO operation.Some parameters may affect engine operation in ways a driver does not expect