Information injection-pump assembly

ZEXEL

106689-4080

1066894080

Rating:

Service parts 106689-4080 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

35A61-00010

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106689-4080

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106689-4080

1066894080

Zexel num

Bosch num

Firm num

Name

106689-4080

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.8

2.75

2.85

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Opposite to the driving side NO.1

Opposite to the driving side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

13

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

385

376

394

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Rack limit

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.6+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

10

7

13

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

(N1+50)-

-

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

N2

Advance angle

deg.

4

3.5

4.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

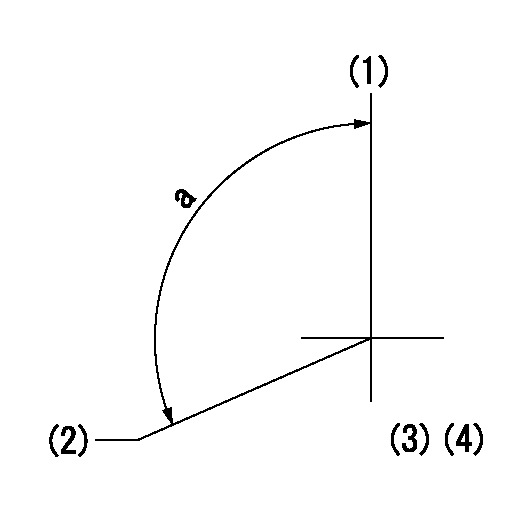

Test data Ex:

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(110deg)

----------

----------

a=(110deg)

Information:

On engines with serial numbers 7LG1-7499, Inlet Air Temperature Sensors have Deutsch HD Connectors, 7LG7500-UP Inlet Air Temperature Sensors have DT Connectors.Schematic

Diagnostic Codes

Functional Test

P-527: Oil Pressure Circuit Test

System Operation

The 3176 system monitors oil pressure with a sensor located in the oil gallery (right side of engine). The oil pressure sensor is supplied with electrical power by the 5 volt sensor supply voltage from the ECM. Note that the 3176 uses oil pressure only as an engine protection function (available for 7LG7500-UP engines). Lack of oil pressure does not prevent the 3176 ECM from starting the engine. The 3176 ECM will still try to start the engine even if oil pressure is low.The 3176 system monitors oil pressure following engine start up and may show a 100-01 Low Oil Pressure Warning Diagnostic Code (46). The Diagnostic Code will not be logged for the first 15 seconds following engine start up, only ACTIVE.The Oil Pressure Sensor can measure oil pressure from 0 kPa (0 psi) to 690 kPa (100 psi).The 3176 oil pressure sensor is supplied with electrical power by the 5 volt sensor supply voltage from the ECM through connector J4/P4 Pin 10 to the Oil Pressure Sensor Connector P17/J17 Pin A. The Oil Pressure Sensor signal line routes from P17/J17 Pin C to J4/P4 pin 27. The Sensor Common routes from J4/P4 Pin 35 to P17/J17 pin B. the +5 V supply is shared with the Coolant Temperature, Inlet Air Temperature, and Coolant Level (if installed) Sensors. The Sensor Common is shared by the Coolant Temperature, and Inlet Air Temperature Sensors.Schematic

Diagnostic Codes

Functional Test

ECAP Example Screen of Oil Pressure Reading P-528: Boost Pressure Circuit Test And Sensor Calibration

System Operation

The 3176 system monitors boost pressure with a sensor located inside the Transducer Module. The boost pressure sensor is supplied with electrical through the Transducer Module Connector (inside the module) pin 1 (+8V). The signal routes through pin 2 (Boost Pressure) and Sensor Common is pin 3. The sensor can only be replaced by replacing the transducer module.The boost pressure is used to reduce smoke emissions during acceleration. 3176 limits the amount of fuel injected until certain boost pressures are reached. It does this by converting boost pressure to "FRC Fuel Post." (as shown on the ECAP status display). The FRC Fuel Pos. is electronic limit on the amount of fuel injected and is based on a ratio of fuel to air being supplied to the cylinders. It operates in a manner similar to the fuel ratio control on an engine with a mechanical governor.The inlet air hose from the air cleaner to the transducer module must be installed. The air inlet serves as a vent for the transducer module and is required for proper operation of the boost pressure sensor.The 3176 Boost Pressure Sensor must be calibrated for a zero boost condition with the engine off. Calibration is accomplished electronically without the need for manual adjustments. The sensor must be recalibrated whenever the ECM or transducer module has

Diagnostic Codes

Functional Test

P-527: Oil Pressure Circuit Test

System Operation

The 3176 system monitors oil pressure with a sensor located in the oil gallery (right side of engine). The oil pressure sensor is supplied with electrical power by the 5 volt sensor supply voltage from the ECM. Note that the 3176 uses oil pressure only as an engine protection function (available for 7LG7500-UP engines). Lack of oil pressure does not prevent the 3176 ECM from starting the engine. The 3176 ECM will still try to start the engine even if oil pressure is low.The 3176 system monitors oil pressure following engine start up and may show a 100-01 Low Oil Pressure Warning Diagnostic Code (46). The Diagnostic Code will not be logged for the first 15 seconds following engine start up, only ACTIVE.The Oil Pressure Sensor can measure oil pressure from 0 kPa (0 psi) to 690 kPa (100 psi).The 3176 oil pressure sensor is supplied with electrical power by the 5 volt sensor supply voltage from the ECM through connector J4/P4 Pin 10 to the Oil Pressure Sensor Connector P17/J17 Pin A. The Oil Pressure Sensor signal line routes from P17/J17 Pin C to J4/P4 pin 27. The Sensor Common routes from J4/P4 Pin 35 to P17/J17 pin B. the +5 V supply is shared with the Coolant Temperature, Inlet Air Temperature, and Coolant Level (if installed) Sensors. The Sensor Common is shared by the Coolant Temperature, and Inlet Air Temperature Sensors.Schematic

Diagnostic Codes

Functional Test

ECAP Example Screen of Oil Pressure Reading P-528: Boost Pressure Circuit Test And Sensor Calibration

System Operation

The 3176 system monitors boost pressure with a sensor located inside the Transducer Module. The boost pressure sensor is supplied with electrical through the Transducer Module Connector (inside the module) pin 1 (+8V). The signal routes through pin 2 (Boost Pressure) and Sensor Common is pin 3. The sensor can only be replaced by replacing the transducer module.The boost pressure is used to reduce smoke emissions during acceleration. 3176 limits the amount of fuel injected until certain boost pressures are reached. It does this by converting boost pressure to "FRC Fuel Post." (as shown on the ECAP status display). The FRC Fuel Pos. is electronic limit on the amount of fuel injected and is based on a ratio of fuel to air being supplied to the cylinders. It operates in a manner similar to the fuel ratio control on an engine with a mechanical governor.The inlet air hose from the air cleaner to the transducer module must be installed. The air inlet serves as a vent for the transducer module and is required for proper operation of the boost pressure sensor.The 3176 Boost Pressure Sensor must be calibrated for a zero boost condition with the engine off. Calibration is accomplished electronically without the need for manual adjustments. The sensor must be recalibrated whenever the ECM or transducer module has

Have questions with 106689-4080?

Group cross 106689-4080 ZEXEL

Daihatsu

Komatsu

Komatsu

Mitsubishi-Heav

Komatsu

Mitsubishi-Heav

Mitsubishi-Heav

Komatsu

106689-4080

INJECTION-PUMP ASSEMBLY