Information injection-pump assembly

ZEXEL

106689-4070

1066894070

Rating:

Service parts 106689-4070 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6215-11-3202

12.

Open Pre:MPa(Kqf/cm2)

27.5{280}

15.

NOZZLE SET

Include in #1:

106689-4070

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106689-4070

1066894070

Zexel num

Bosch num

Firm num

Name

106689-4070

INJECTION-PUMP ASSEMBLY

14CA PE6P,6PD PE

14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

255

255

Overflow valve opening pressure

kgf/cm2

2.6

2.6

2.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15.8

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

387

384

390

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Remarks

Standard point A's rack position same as row L

Standard point A's rack position same as row L

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.3+-0.5

Pump speed

r/min

340

340

340

Average injection quantity

mm3/st.

20

18.5

21.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Timer adjustment

Pump speed

r/min

[N1+50]-

-

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

2.5

2

3

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

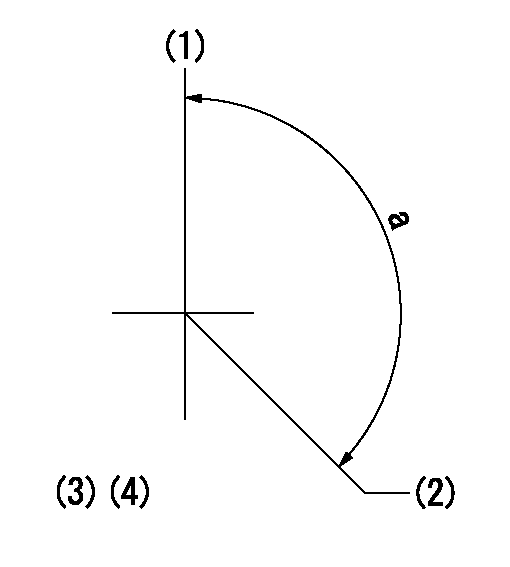

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(150deg)

----------

----------

a=(150deg)

Information:

Before using this section, be sure that you have:1. Gathered information about the complaint to adequately describe the symptoms.2. Verified that the complaint is not due to normal engine operation.3. Repaired all ACTIVE Diagnostic Codes.Then, Identify probable causes using the procedure in this section which best describes the symptoms. The narrow the probable causes using:What happened, and when?Under what conditions?What else occurred?When did the symptoms begin (and what else happened at that time)?Do they correlate to probable causes?Did they occur at the same time as the symptoms?Are some logged repeatedly?Are they related to this symptom?Do they have common probable causes?Finally, test each probable cause using the tests suggested by the procedure. Be sure to check connectors, especially on intermittent problems!P-301: Engine Will Not Crank

P-302: Engine Cranks But Will Not Start

P-303: Engine Misfires, Runs Rough Or Is Unstable

P-304: Low Power/Poor Or No Response To Throttle

P-305: Cruise Or PTO Does Not Function

P-310: Intermittent Engine Shutdowns

P-311: Intermittent Low Power Or Power Cutouts

P-312: Intermittent Cruise Or PTO Drop-Out

P-320: ECAP/DDT Will Not Communicate With 3176 System

P-321: ECM Will Not Accept Factory Passwords

P-322: Diagnostic/Warning Lamp Is Malfunctioning

P-302: Engine Cranks But Will Not Start

P-303: Engine Misfires, Runs Rough Or Is Unstable

P-304: Low Power/Poor Or No Response To Throttle

P-305: Cruise Or PTO Does Not Function

P-310: Intermittent Engine Shutdowns

P-311: Intermittent Low Power Or Power Cutouts

P-312: Intermittent Cruise Or PTO Drop-Out

P-320: ECAP/DDT Will Not Communicate With 3176 System

P-321: ECM Will Not Accept Factory Passwords

P-322: Diagnostic/Warning Lamp Is Malfunctioning

Have questions with 106689-4070?

Group cross 106689-4070 ZEXEL

Daihatsu

Komatsu

Komatsu

Mitsubishi-Heav

Komatsu

Mitsubishi-Heav

Mitsubishi-Heav

106689-4070

INJECTION-PUMP ASSEMBLY