Information injection-pump assembly

BOSCH

F 019 Z20 223

f019z20223

ZEXEL

106685-4530

1066854530

MITSUBISHI-HEAV

34A6500110

34a6500110

Rating:

Service parts 106685-4530 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

29.4(300)

15.

NOZZLE SET

Include in #1:

106685-4530

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z20 223

f019z20223

ZEXEL

106685-4530

1066854530

MITSUBISHI-HEAV

34A6500110

34a6500110

Zexel num

Bosch num

Firm num

Name

F 019 Z20 223

34A6500110 MITSUBISHI-HEAV

INJECTION-PUMP ASSEMBLY

S6B3 * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

S6B3 * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131425-1720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

13.4

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

404

395

413

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

93.3

93.3

Boost pressure

mmHg

700

700

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.3+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

30

27

33

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

750

750

750

Rack position

R1-3.2

Boost pressure

kPa

32

29.3

34.7

Boost pressure

mmHg

240

220

260

Boost compensator adjustment_02

Pump speed

r/min

750

750

750

Rack position

R1(13.4)

Boost pressure

kPa

80

73.3

86.7

Boost pressure

mmHg

600

550

650

Test data Ex:

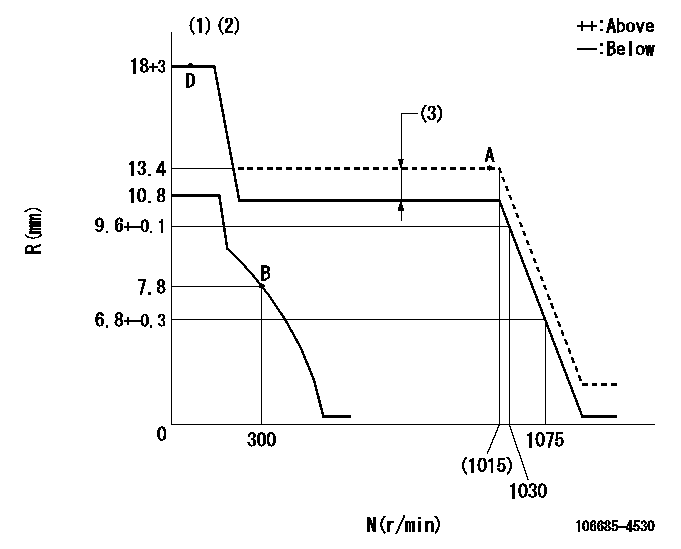

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

K=14 BCL=3.2+-0.1mm

----------

----------

K=14 BCL=3.2+-0.1mm

----------

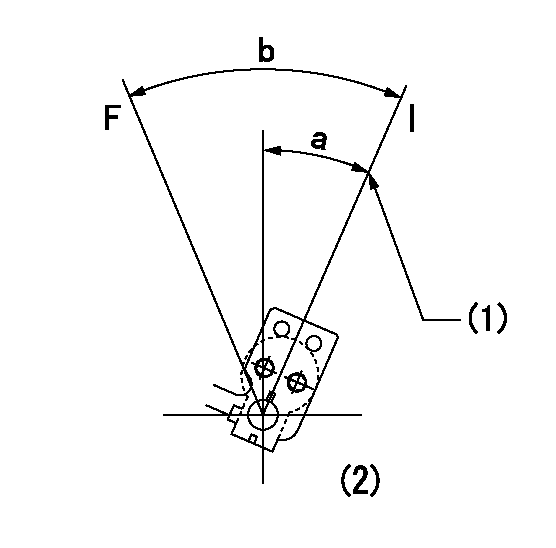

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At the center of the lever key groove

----------

----------

a=9deg+-5deg b=28.5deg+-5deg

----------

----------

a=9deg+-5deg b=28.5deg+-5deg

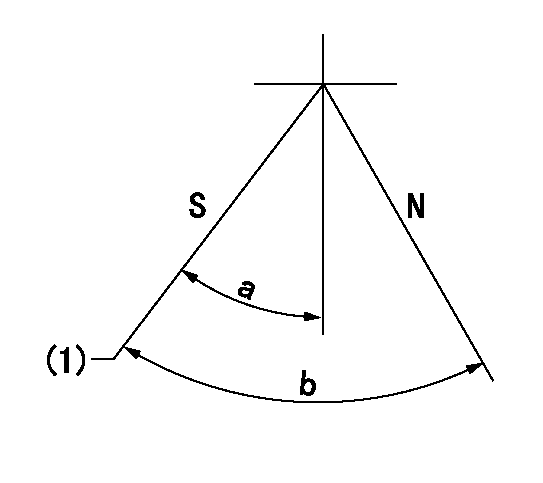

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa, rack position bb

----------

aa=0r/min bb=1-0.5mm

----------

a=33deg+-5deg b=(73deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=33deg+-5deg b=(73deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

1. Disconnect plug P14 from receptacle J14. The locking ring helps identify P14 from J14. Check the connections for damaged wires or pins and corrosion. Also check that the pins are at the proper height in the connector. Check that the wires and pins are tight in the connectors by pulling (slightly) on each wire of each connector (including the breakout "T").2. Install 8T8694 Adapter (five pin breakout "T") between J14 and P14. Twist the locking rings to secure the connections.3. Connect the voltmeter as shown. Check for the appropriate voltages between the lettered "T" pins as explained in Steps 4 through 7.4. Pin A (+) to pin B (ground) system voltage should be approximately 12 volts DC with key on (no accessories). Minimum voltage is 11.0 volts DC. Diagnosis - Using the truck wiring schematic, check wires A and B and connections from J14 through the truck wiring harness back to the battery for proper voltage.5. If the voltage check between pins A and B is less than 11.0 volts with the key on, check the voltage drop from pin B to the negative battery post while cranking. For this test, the common lead (black) should be connected to the negative battery post first. Then place the positive (red) lead into pin B. (Pin B is chassis ground.) Voltage should be less than .5 volts DC when cranking. Diagnosis - If the voltage drop is greater than .5 volts DC, check wire B and connections (including the battery post connections) from J14 to battery negative. Follow the truck wiring schematic to trace the electrical path from J14 to chassis ground. Step 6 checks the proper functioning of the truck wiring, vehicle speed sensor and vehicle speed buffer. If proper vehicle speed is present on the appropriate status screens of the 3176 (7X1055) DDT or the (8T8697) ECAP service tools during road test than Step 6 is not necessary.6. Pin C to pin B:* 0 volts when stopped.* Up to 2.3 volts DC with the transmission output shaft turning and the speedometer disconnected (open circuit).

Remove the axle shafts or disconnect the drive shaft from the transmission to perform this test. See the truck manufacturer's instructions for the correct procedure(s).

Diagnosis: Remove magnetic pickup (vehicle speed sensor) from transmission. If pickup has collected significant metal debris, wipe it clean. Check the magnetic pickup per the manufactures specifications. Install a properly functioning magnetic pickup to the proper depth and reconnect to the vehicle speed buffer. Repeat Step 6. The problem may reappear if transmission fluid is contaminated. Change transmission fluid if necessary.* Check wires and connectors for damage or corrosion from the magnetic pickup to vehicle speed buffer.* Replace vehicle speed buffer (Caterpillar supplied part).

Vehicle Speed Buffer (1) Magnetic Pickup (2) in transmission.7. Pin D to pin B (static check):* Disconnect the magnetic pickup (in transmission) from the input wires of the vehicle speed buffer. With the key on, the voltage should be 4.5-7.5 volts DC. Diagnosis - If the

Remove the axle shafts or disconnect the drive shaft from the transmission to perform this test. See the truck manufacturer's instructions for the correct procedure(s).

Diagnosis: Remove magnetic pickup (vehicle speed sensor) from transmission. If pickup has collected significant metal debris, wipe it clean. Check the magnetic pickup per the manufactures specifications. Install a properly functioning magnetic pickup to the proper depth and reconnect to the vehicle speed buffer. Repeat Step 6. The problem may reappear if transmission fluid is contaminated. Change transmission fluid if necessary.* Check wires and connectors for damage or corrosion from the magnetic pickup to vehicle speed buffer.* Replace vehicle speed buffer (Caterpillar supplied part).

Vehicle Speed Buffer (1) Magnetic Pickup (2) in transmission.7. Pin D to pin B (static check):* Disconnect the magnetic pickup (in transmission) from the input wires of the vehicle speed buffer. With the key on, the voltage should be 4.5-7.5 volts DC. Diagnosis - If the