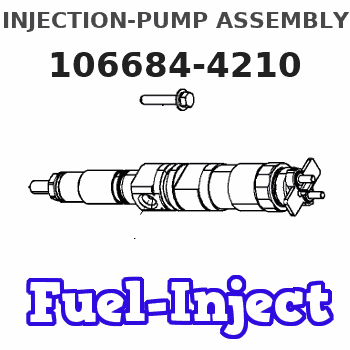

Information injection-pump assembly

ZEXEL

106684-4210

1066844210

Rating:

Service parts 106684-4210 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6212-11-3202

12.

Open Pre:MPa(Kqf/cm2)

24.5{250}

15.

NOZZLE SET

Include in #1:

106684-4210

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106684-4210

1066844210

Zexel num

Bosch num

Firm num

Name

106684-4210

INJECTION-PUMP ASSEMBLY

14CA PE6P,6PD PE

14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

14.1

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

345

342

348

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Remarks

Standard point's rack position same as 106682-9270 in row L.

Standard point's rack position same as 106682-9270 in row L.

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.4+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

20

18.5

21.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

-

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

330

320

340

Fixing the rack

*

Rack limit

*

Test data Ex:

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(150deg)

----------

----------

a=(150deg)

Information:

Oiler Feed Adjustment

If necessary, adjust the lubricator to release approximately four drops of fluid per minute into the starting motor air stream. Be sure there is NO fuel supply to the engine. 1. Push on the air start control lever (1) to crank the engine.2. Count the drops of fluid per minute that are released into the air stream. Turn the needle valve knob (3) counterclockwise to increase the flow and clockwise to decrease the flow of fluid into the air stream.Collector Bowl

Some air starters may be equipped with a collector bowl. The bowl collects used oil after the oil has lubricated the vanes. The bowl also collects moisture condensation from the compressed air. When the collector bowl becomes half full, drain the used lubricant. Never fill the lubricator bowl with oil from the collector bowl- use clean lubricant.Air Tank (If Equipped)

For good life of the air starting motor, the air supply must be free of dirt and water. The air starter requires adequate air pressure in order to operate.* Drain water from the air tank (if equipped). Open the drain valve on the bottom of the air tank to drain the condensation and oil carryover.* Check the air supply pressure. The air starting motor requires a minimum of 620 kPa (90 psi) of air pressure to operate properly. The maximum air pressure must not exceed 1550 kPa (225 psi). The normal air pressure will be 758 kPa (110 psi) to 965 kPa (140 psi).Engine Air Cleaner

Check Air Cleaner Service Indicator

Typical air cleaner indicator, mounted on the air cleaner housing. Your engine may be equipped with a different indicator.A service indicator (if equipped) may be mounted on the air cleaner or in a remote location. A colored piston showing in the window indicates the need for servicing the air cleaner. Observe the air cleaner service indicator. Clean or replace the air cleaner element when the yellow diaphragm enters the red zone or the red piston locks in the visible position. If the air cleaner indicator shows red at any time, clean the filter element or install a new air cleaner element.

Never service the air cleaner with the engine running since this will allow dirt to enter the engine.

If your air cleaner element becomes plugged, the air can split the element filter material. Unfiltered air will drastically accelerate internal engine wear. Your Caterpillar dealer has air filter elements to service this unit. Contact your Caterpillar dealer for the correct filter element. If equipped with a Light Duty air cleaner element, refer to the 50 Hour interval for information.Single Stage Air Cleaner Elements

Remove and Install Air Cleaner Elements

1. Remove the air cleaner cover (1) and element (2).2. Seal the turbocharger air inlet (3) so that debris can not enter the inlet. Use tape, or secure a clean cloth over the opening.3. Clean the inside of the air cleaner cover and body.4. Inspect the replacement element for damage, dirt or debris.5. Remove the seal from the turbocharger inlet.6. Install a clean,

If necessary, adjust the lubricator to release approximately four drops of fluid per minute into the starting motor air stream. Be sure there is NO fuel supply to the engine. 1. Push on the air start control lever (1) to crank the engine.2. Count the drops of fluid per minute that are released into the air stream. Turn the needle valve knob (3) counterclockwise to increase the flow and clockwise to decrease the flow of fluid into the air stream.Collector Bowl

Some air starters may be equipped with a collector bowl. The bowl collects used oil after the oil has lubricated the vanes. The bowl also collects moisture condensation from the compressed air. When the collector bowl becomes half full, drain the used lubricant. Never fill the lubricator bowl with oil from the collector bowl- use clean lubricant.Air Tank (If Equipped)

For good life of the air starting motor, the air supply must be free of dirt and water. The air starter requires adequate air pressure in order to operate.* Drain water from the air tank (if equipped). Open the drain valve on the bottom of the air tank to drain the condensation and oil carryover.* Check the air supply pressure. The air starting motor requires a minimum of 620 kPa (90 psi) of air pressure to operate properly. The maximum air pressure must not exceed 1550 kPa (225 psi). The normal air pressure will be 758 kPa (110 psi) to 965 kPa (140 psi).Engine Air Cleaner

Check Air Cleaner Service Indicator

Typical air cleaner indicator, mounted on the air cleaner housing. Your engine may be equipped with a different indicator.A service indicator (if equipped) may be mounted on the air cleaner or in a remote location. A colored piston showing in the window indicates the need for servicing the air cleaner. Observe the air cleaner service indicator. Clean or replace the air cleaner element when the yellow diaphragm enters the red zone or the red piston locks in the visible position. If the air cleaner indicator shows red at any time, clean the filter element or install a new air cleaner element.

Never service the air cleaner with the engine running since this will allow dirt to enter the engine.

If your air cleaner element becomes plugged, the air can split the element filter material. Unfiltered air will drastically accelerate internal engine wear. Your Caterpillar dealer has air filter elements to service this unit. Contact your Caterpillar dealer for the correct filter element. If equipped with a Light Duty air cleaner element, refer to the 50 Hour interval for information.Single Stage Air Cleaner Elements

Remove and Install Air Cleaner Elements

1. Remove the air cleaner cover (1) and element (2).2. Seal the turbocharger air inlet (3) so that debris can not enter the inlet. Use tape, or secure a clean cloth over the opening.3. Clean the inside of the air cleaner cover and body.4. Inspect the replacement element for damage, dirt or debris.5. Remove the seal from the turbocharger inlet.6. Install a clean,

Have questions with 106684-4210?

Group cross 106684-4210 ZEXEL

Komatsu

106684-4210

INJECTION-PUMP ASSEMBLY