Information injection-pump assembly

ZEXEL

106684-4120

1066844120

KOMATSU

6166711650

6166711650

Rating:

Service parts 106684-4120 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6166-11-3100

12.

Open Pre:MPa(Kqf/cm2)

26.0{265}

15.

NOZZLE SET

Include in #1:

106684-4120

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106684-4120

1066844120

KOMATSU

6166711650

6166711650

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

17.4

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

460

455

465

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Remarks

Standard point A's rack position same as 106682-4880 in row L.

Standard point A's rack position same as 106682-4880 in row L.

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.2+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

36.5

31.5

41.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Remarks

Rack limit setting R = 18.9+0.2

Rack limit setting R = 18.9+0.2

Test data Ex:

Timing setting

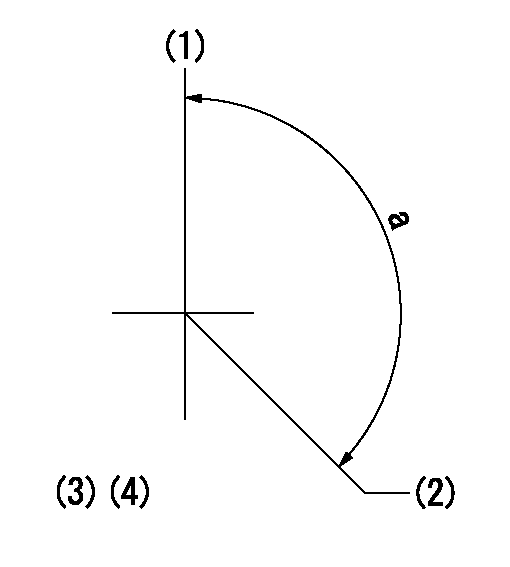

(1)Pump vertical direction

(2)Position of spline gear's aligning mark at No 1 cylinder's beginning of injection (key position)

(3)B.T.D.C.: aa

(4)-

----------

aa=34deg

----------

a=(130deg)

----------

aa=34deg

----------

a=(130deg)

Information:

Caterpillar Reference MaterialSEBD0518 Know Your Cooling SystemSEBD0640 Oil and Your EngineSEBD0717 Diesel Fuels and Your EngineSEBD0970 Coolant and Your EngineSEBU5898 Cold Weather Recommendations Operation and Maintenance ManualSEBU6310 EMA Engine Oil Data BookSEHS7067 Fuels for Caterpillar Diesel EnginesSEHS7808 Special Instruction-6V3060 Low Emission System TesterSEHS8622 Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSELF5052 Emission Related Components WarrantyLEDT5092 Driving Techniques For Maximum Fuel EconomyLEBT8121 Truck Engine Application and Installation GuideLEGT5087 Truck Engine Application and Installation GuideLEKQ3363 Caterpillar Engine Data Sheet 60.1 - "Fuels Recommended For Use In Caterpillar Truck Engines"LEXT7056 Performance Analysis Report (PAR) Testing for 3406B PEEC Truck EnginesSEHS9031 Storage Procedure for Caterpillar ProductsSENRXXXX 3406B PEEC Service Manual (8TC1 and Up, 5YG1-UP) (Contact your Caterpillar dealer for the correct Service Manual for your engine).SEBR0514 Low Emission SystemSEBF8029 Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062 Guideline for Reusable Parts - Cleaning and Inspection of Air FiltersSEBD0794 3400 Engine-Major Component Performance GuidePEDP7122 Question & Answer BookletPEHP7504 CAT Engine Oil Spec SheetsPEHP7505 CAT Diesel Engine Oil Spec SheetsAll of the above publications are available through your Caterpillar dealer. The following Special Instructions pertain to the operation, maintenance, diagnostic tooling and programming of the PEEC system. Some of these publications will be included in the tool kits, the others will be available thru your Caterpillar dealer.SEHS8741 Using the 8C5919 3406B PEEC Service Program ModuleSEHS8742 Using the 8T8697 Electronic Control Analyzer Programmer (ECAP)SEHS8743 Using the 8C4629 Digital Diagnostic Tool DDT with the 3406B Programmable Electronic Engine Control PEEC ModuleSEHS8746 Using the 1U5540 Tool GroupSEHS8747 PEEC Screen Map(s).All of the above publications are available through your Caterpillar dealer. Additional Reference MaterialASTM D217-68 - Worked PenetrationASTM D2896 TBN MeasurementsASTM Specs can normally be obtained from your local technological society, library or college.SAE J313 Diesel FuelsSAE J754 NomenclatureSAE J183 ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.