Information injection-pump assembly

ZEXEL

106684-4080

1066844080

KOMATSU

6215751120

6215751120

Rating:

Cross reference number

ZEXEL

106684-4080

1066844080

KOMATSU

6215751120

6215751120

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

255

255

Overflow valve opening pressure

kgf/cm2

2.6

2.6

2.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

17.1

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

447

443.5

450.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Remarks

Standard point A's rack position same as row L

Standard point A's rack position same as row L

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.8+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

20

18.5

21.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Remarks

Rack limit setting R = 17.6+0.2

Rack limit setting R = 17.6+0.2

Test data Ex:

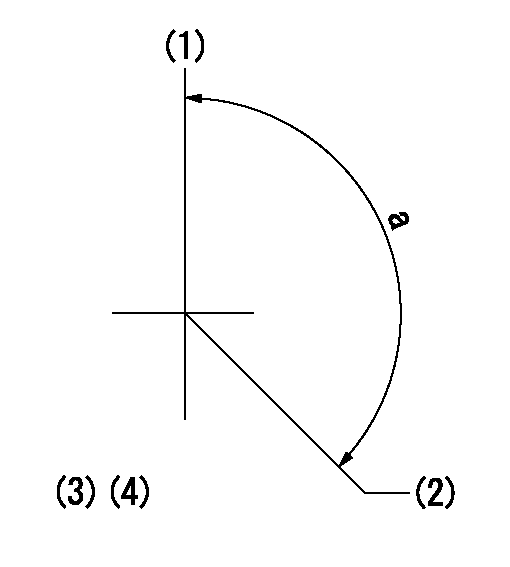

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(150deg)

----------

----------

a=(150deg)

Information:

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil leve with the engine stopped. 2. Maintain the oil leve between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to calibrating the oil level gauge in the Dipsticks section of this manual or consult your Caterpillar dealer before operating the engine. 3. Add oil if necessary. See Refill Capacities and Lubricant Specifications for the size of your engine crankcase and proper oil to use. Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary filters, refer to the OEM or manufacturer's instructions.Leaks and Loose Connections

Inspect the Engine

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before servicing. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses for cracks and loose clamps. * Inspect the fan and accessory drive belts for cracks, breaks or other damage.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a 2 or 3 belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break. * Inspect the water pump for leaks. Check weep hole for water pump breather filter, 4N1400 (1), blockage and replace if necessary. * Inspect the engine for oil leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers. * Inspect the fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses. * Inspect wiring for loose connections and worn or frayed wires. * Inspect air intake system hoses and elbows for cracks and loose clamps. * Inspect engine-to-frame ground strap for good connection and condition.* All guards must be in place. Repair or replace missing or