Information injection-pump assembly

BOSCH

9 400 619 872

9400619872

ZEXEL

106682-9340

1066829340

KOMATSU

6212711340

6212711340

Rating:

Service parts 106682-9340 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

24.5{250}

15.

NOZZLE SET

Include in #1:

106682-9340

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 872

9400619872

ZEXEL

106682-9340

1066829340

KOMATSU

6212711340

6212711340

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

13.5

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

371

368

374

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.6+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

13

11.5

14.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

380

370

390

Fixing the lever

*

Rack limit

*

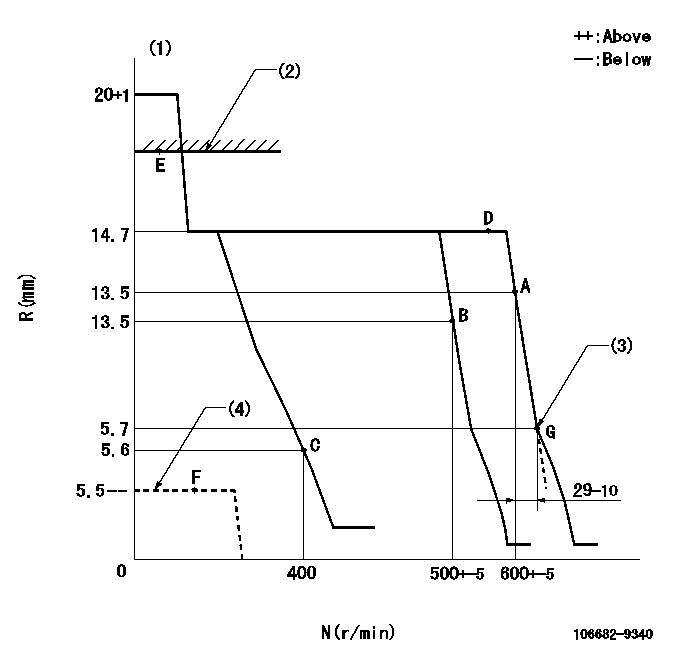

Test data Ex:

Governor adjustment

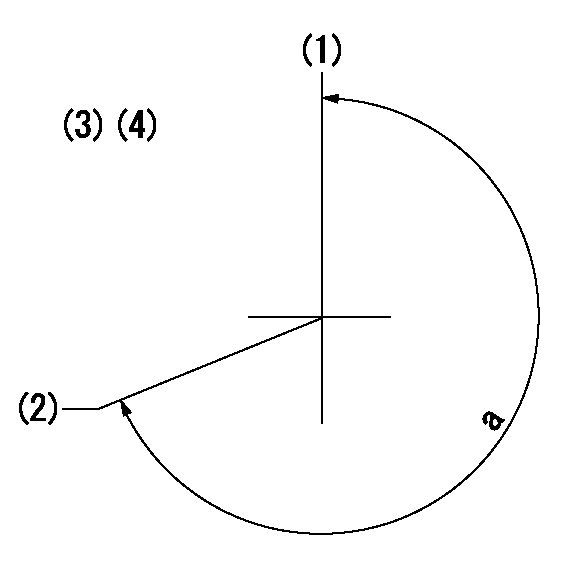

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Set idle sub-spring

(4)Stop lever at stopping (with the stop lever at full)

----------

K=15 RAL=15.2+0.2mm

----------

----------

K=15 RAL=15.2+0.2mm

----------

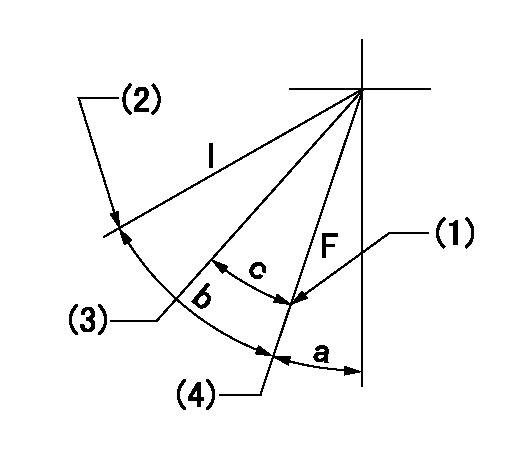

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)Set the pump speed at aa

(4)Set the pump speed at bb (at delivery)

----------

aa=500r/min bb=600r/min

----------

a=2deg+-5deg b=14deg+-5deg c=7deg+-5deg

----------

aa=500r/min bb=600r/min

----------

a=2deg+-5deg b=14deg+-5deg c=7deg+-5deg

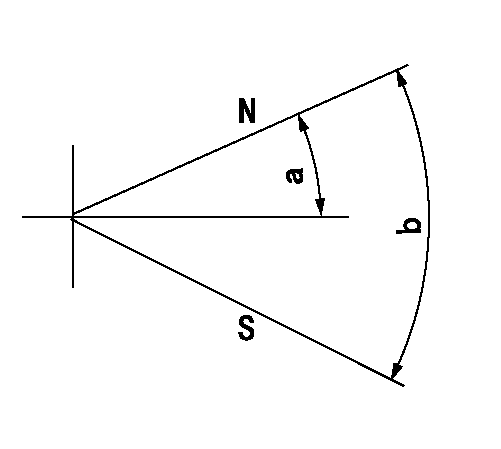

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(260deg)

----------

----------

a=(260deg)

Information:

The problems in this section are problems that do come about and are normally called "low power". These problems are not necessarily more common than engine problems, but they are possible problems which you need to read and check before an engine is disassembled.Read all of the items but make sure the first three are checked completely before making any engine test.Possible Causes/Corrections

Tachometer Error

To check, connect a tachometer of known accuracy to the engine. Run the engine and make a comparison of the readings of the vehicle and test tachometers. If vehicle tachometer is defective, make repairs as necessary or install a new tachometer.Engine Operated At High Altitude

Less oxygen at higher altitudes causes the engine horsepower to go down. There is no effect on the horsepower of the engine for the first 2280 m (7500 ft) above sea level of operation.Brakes Do Not Completely Release

Check the brakes by feeling all the brake drums. If the brakes of a wheel do not completely release, the brake drum for that wheel will be hotter than the brake drums for the other wheels. With the truck lifted with a jack, the wheels must have free rotation when turned by hand.Extra Engine Driven Equipment

Air compressors, hydraulic pumps, alternator, and other engine driven equipment that has damage, or that was not installed correctly, or that is not in correct adjustment, can take more horsepower to drive than expected. If necessary, disconnect the equipment and test the engine.Speedometer Error

A defective speedometer does not give the correct speed or the correct indication of fuel consumption. An indication of low speed can cause the operator to feel that he has a power problem.Speeds Too High

The need for more horsepower is easy to see as the speed of the vehicle is increased. This is especially true if the front of the vehicle has a large surface area. Application personnel can give you the horsepower necessary for different vehicle designs at different speeds.Overload On Vehicle

Application personnel can give you the horsepower needs for different vehicles.High Moving Resistance

Soft ground conditions cause a need for more horsepower. To see if the problem is the engine, test the vehicle on a surface known to be good, or test on a chassis dynamometer.High Wind Resistance

The horsepower needs for a truck can be divided into two parts. Part of the horsepower is used to move the vehicle and part is used to get through the resistance of the wind. The horsepower necessary to get through the resistance of the wind will increase as the vehicle is used at higher speeds. Vehicles with a large front area have a higher wind resistance and take more horsepower than those with a small front area. Some types of trucks, for example those used for the transportation of automobiles and or boats have high wind resistance even if the front area is small. Moving against the wind has the same effect on wind resistance as does higher vehicle speed.Power Loss In Drive Gears

It is possible for a

Tachometer Error

To check, connect a tachometer of known accuracy to the engine. Run the engine and make a comparison of the readings of the vehicle and test tachometers. If vehicle tachometer is defective, make repairs as necessary or install a new tachometer.Engine Operated At High Altitude

Less oxygen at higher altitudes causes the engine horsepower to go down. There is no effect on the horsepower of the engine for the first 2280 m (7500 ft) above sea level of operation.Brakes Do Not Completely Release

Check the brakes by feeling all the brake drums. If the brakes of a wheel do not completely release, the brake drum for that wheel will be hotter than the brake drums for the other wheels. With the truck lifted with a jack, the wheels must have free rotation when turned by hand.Extra Engine Driven Equipment

Air compressors, hydraulic pumps, alternator, and other engine driven equipment that has damage, or that was not installed correctly, or that is not in correct adjustment, can take more horsepower to drive than expected. If necessary, disconnect the equipment and test the engine.Speedometer Error

A defective speedometer does not give the correct speed or the correct indication of fuel consumption. An indication of low speed can cause the operator to feel that he has a power problem.Speeds Too High

The need for more horsepower is easy to see as the speed of the vehicle is increased. This is especially true if the front of the vehicle has a large surface area. Application personnel can give you the horsepower necessary for different vehicle designs at different speeds.Overload On Vehicle

Application personnel can give you the horsepower needs for different vehicles.High Moving Resistance

Soft ground conditions cause a need for more horsepower. To see if the problem is the engine, test the vehicle on a surface known to be good, or test on a chassis dynamometer.High Wind Resistance

The horsepower needs for a truck can be divided into two parts. Part of the horsepower is used to move the vehicle and part is used to get through the resistance of the wind. The horsepower necessary to get through the resistance of the wind will increase as the vehicle is used at higher speeds. Vehicles with a large front area have a higher wind resistance and take more horsepower than those with a small front area. Some types of trucks, for example those used for the transportation of automobiles and or boats have high wind resistance even if the front area is small. Moving against the wind has the same effect on wind resistance as does higher vehicle speed.Power Loss In Drive Gears

It is possible for a