Information injection-pump assembly

ZEXEL

106682-9290

1066829290

Rating:

Service parts 106682-9290 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6162-13-3702

12.

Open Pre:MPa(Kqf/cm2)

26.0{265}

15.

NOZZLE SET

Include in #1:

106682-9290

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106682-9290

1066829290

Zexel num

Bosch num

Firm num

Name

106682-9290

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131424-7120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

16.6

Pump speed

r/min

875

875

875

Average injection quantity

mm3/st.

425

421

429

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

57.3

57.3

Boost pressure

mmHg

430

430

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.9+-0.5

Pump speed

r/min

335

335

335

Average injection quantity

mm3/st.

21

16

26

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

410

410

430

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

14.6

Boost pressure

kPa

9.3

6.6

12

Boost pressure

mmHg

70

50

90

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

17.8

Boost pressure

kPa

44

37.3

50.7

Boost pressure

mmHg

330

280

380

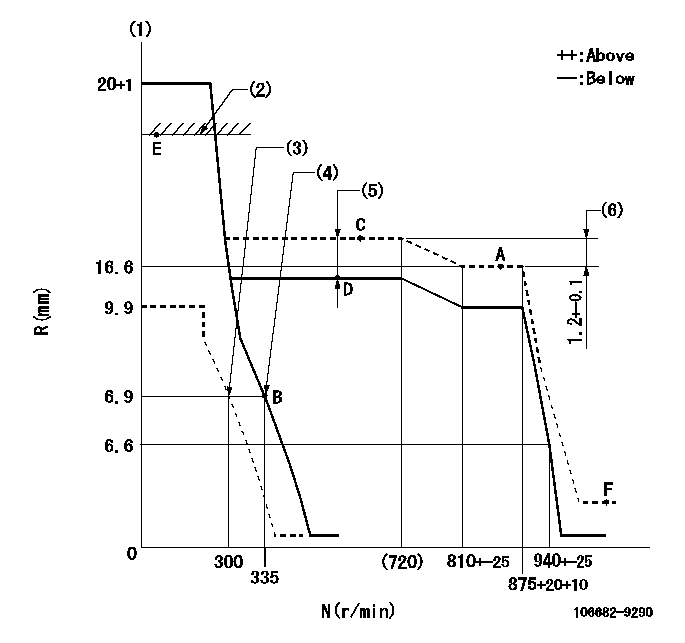

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Set idle sub-spring

(4)Main spring setting

(5)Boost compensator stroke: BCL

(6)Rack difference between N = N1 and N = N2

----------

K=21 BCL=3.2+-0.1mm N1=875r/min N2=650r/min

----------

----------

K=21 BCL=3.2+-0.1mm N1=875r/min N2=650r/min

----------

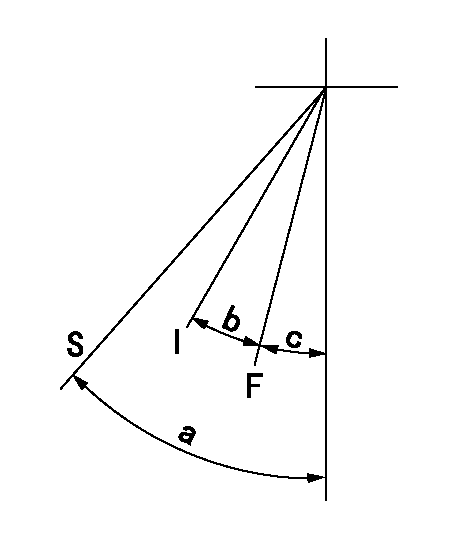

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=52deg+-5deg b=(24deg)+-5deg c=(15deg)+-5deg

----------

----------

a=52deg+-5deg b=(24deg)+-5deg c=(15deg)+-5deg

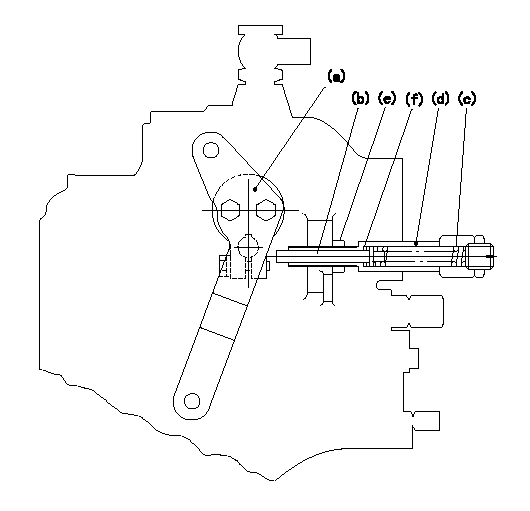

0000001501 LEVER

1. Adjustment of the control lever

(1)Perform idling with the speed lever (a) contacting the pushrod (b) At this time, confirm that the spring (c) is not compressed by speed lever (a)'s operating torque.

(2)To set the stop position, compress spring (c) using the speed lever (a) and adjust the rack so that it contacts the guide screw at position L1. Then, set and fix using the lock nut (e).

Adjust rack position at this time using shim (f).

(3)After pulling the speed lever (a) in the stop direction and releasing it, confirm that it returns to the idle position.

----------

L1=0.2~2mm

----------

----------

L1=0.2~2mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Start By:

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

a. remove crankshaft rear seal and wear sleeve1. Loosen the bolts that hold the oil pan and oil plan plate to the cylinder block. Remove the bolts that hold the oil pan plate to the flywheel housing.2. Install spacers between the oil pan plate and the cylinder block to hold the oil pan plate away from the flywheel housing. 3. Remove turbocharger oil drain tube (1).4. Remove the bolt to clip (3).5. Install tool (A) and fasten a hoist as shown. Remove bolts (4) and remove flywheel housing (2). The weight of the flywheel housing is 39 kg (85 lb.). The following steps are for the installation of the flywheel housing.6. Clean the old gasket from the surfaces of the cylinder block and flywheel housing that make contact with each other. Install a new gasket on the cylinder block.7. Install two 1/2" - 13 NC guide bolts in the cylinder block. Install tool (A) on the flywheel housing. Fasten a hoist and put the flywheel housing in position on the guide bolts. Install all but two bolts in the flywheel housing. Remove tool (A) and the guide bolts. Install the other two bolts. Tighten the flywheel housing bolts in the sequence as shown. 8. Cut the bottom of the gasket even with the flywheel housing and cylinder block. Put 5H2471 Gasket Cement on the bottom of the gasket where the gasket makes contact with the gasket for the oil pan plate. Remove shims from each side of the engine. Tighten all of the oil pan bolts. Install the bolts that hold the oil pan plate to the flywheel housing.9. Install the bolt to clip (3). Install turbocharger oil drain tube (1).End By:a. install crankshaft rear seal and wear sleeve

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

a. remove crankshaft rear seal and wear sleeve1. Loosen the bolts that hold the oil pan and oil plan plate to the cylinder block. Remove the bolts that hold the oil pan plate to the flywheel housing.2. Install spacers between the oil pan plate and the cylinder block to hold the oil pan plate away from the flywheel housing. 3. Remove turbocharger oil drain tube (1).4. Remove the bolt to clip (3).5. Install tool (A) and fasten a hoist as shown. Remove bolts (4) and remove flywheel housing (2). The weight of the flywheel housing is 39 kg (85 lb.). The following steps are for the installation of the flywheel housing.6. Clean the old gasket from the surfaces of the cylinder block and flywheel housing that make contact with each other. Install a new gasket on the cylinder block.7. Install two 1/2" - 13 NC guide bolts in the cylinder block. Install tool (A) on the flywheel housing. Fasten a hoist and put the flywheel housing in position on the guide bolts. Install all but two bolts in the flywheel housing. Remove tool (A) and the guide bolts. Install the other two bolts. Tighten the flywheel housing bolts in the sequence as shown. 8. Cut the bottom of the gasket even with the flywheel housing and cylinder block. Put 5H2471 Gasket Cement on the bottom of the gasket where the gasket makes contact with the gasket for the oil pan plate. Remove shims from each side of the engine. Tighten all of the oil pan bolts. Install the bolts that hold the oil pan plate to the flywheel housing.9. Install the bolt to clip (3). Install turbocharger oil drain tube (1).End By:a. install crankshaft rear seal and wear sleeve

Have questions with 106682-9290?

Group cross 106682-9290 ZEXEL

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

106682-9290

INJECTION-PUMP ASSEMBLY