Information injection-pump assembly

BOSCH

9 400 613 392

9400613392

ZEXEL

106682-9264

1066829264

KOMATSU

6215711810

6215711810

Rating:

Service parts 106682-9264 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

24.5{250}

15.

NOZZLE SET

Include in #1:

106682-9264

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 613 392

9400613392

ZEXEL

106682-9264

1066829264

KOMATSU

6215711810

6215711810

Zexel num

Bosch num

Firm num

Name

9 400 613 392

6215711810 KOMATSU

INJECTION-PUMP ASSEMBLY

SA12V140 * K 14CA PE6P,6PD PE

SA12V140 * K 14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

14.6

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

520

515

525

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Remarks

Standard point A's rack position same as row R

Standard point A's rack position same as row R

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.3+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

21.5

20

23

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

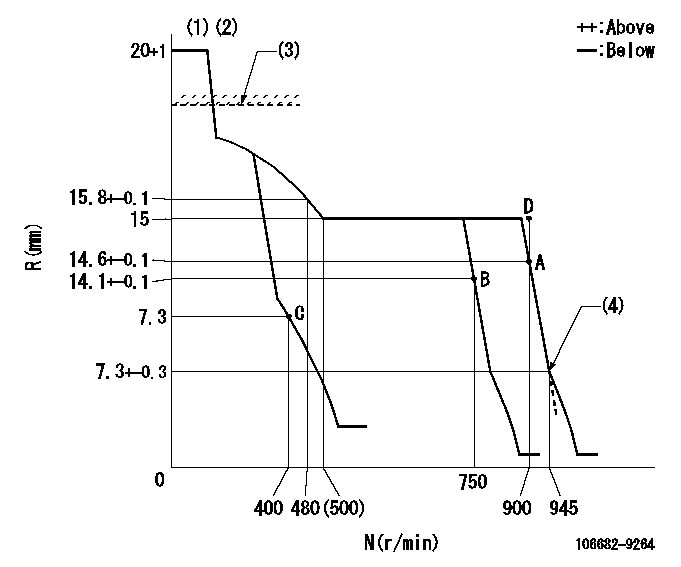

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT for 106684-4203; RAL

(4)Idle sub spring setting: L1.

----------

K=24 RAL=15.5+0.2mm L1=7.3-0.2mm

----------

----------

K=24 RAL=15.5+0.2mm L1=7.3-0.2mm

----------

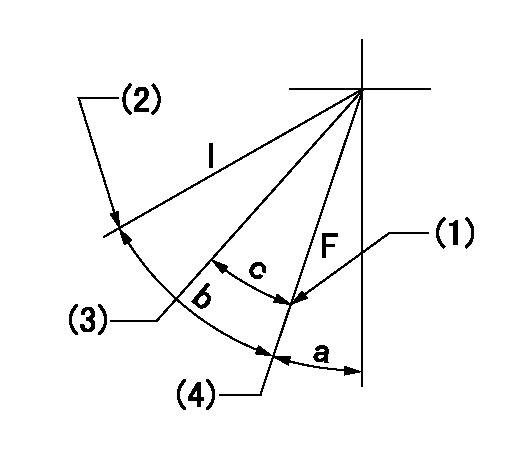

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)Set the pump speed at aa

(4)Set the pump speed at bb (at delivery)

----------

aa=750r/min bb=900r/min

----------

a=6deg+-5deg b=34deg+-5deg c=9deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=6deg+-5deg b=34deg+-5deg c=9deg+-5deg

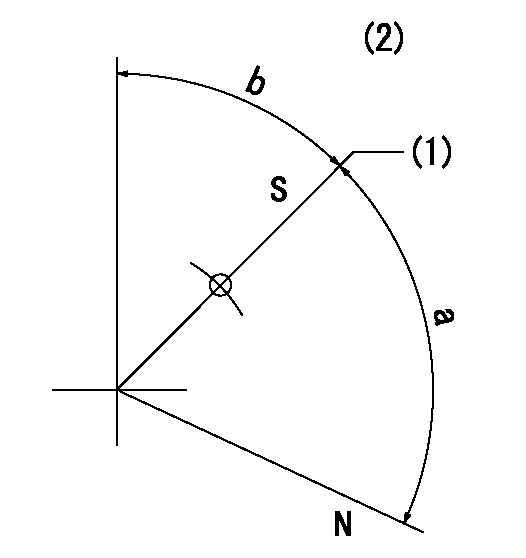

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)No return spring

----------

aa=0r/min bb=1-0.5mm

----------

a=(73deg) b=43.5deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=(73deg) b=43.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Start By:a. remove timing gear cover 1. Remove bolt (1) and washer that fastens the weight assembly (2).

Weight assembly must have support during removal to prevent damage to components.

2. Install tooling (A) and remove the weight assembly.Install Automatic Timing Advance Unit

1. Install washer and bolt (1). With the fuel pump housing cover removed, turn the fuel pump camshaft in the direction of engine rotation until tool (A) can be installed in the notch of the camshaft. 2. To time the fuel injection pump to the engine with the front timing cover removed, follow Steps 3 and 4. With the timing cover installed, see Steps 6 and 7. No. 1 piston at top center (TC) on the compression stroke is the starting point for all timing procedures. The engine is seen from the flywheel end when direction of crankshaft rotation is given.3. Turn the crankshaft counterclockwise until the "C" on the crankshaft and camshaft and camshaft gears are in alignment. 4. Remove the plug and install tool (B) in the flywheel housing.5. To find top center compression stroke for No. 1 piston, turn the flywheel clockwise (opposite of engine rotation) approximately 30°. This procedure is to remove all end play from timing gears.6. Turn the flywheel counterclockwise (direction of engine rotation) until tool (B) can be installed in the flywheel. The piston is at top center. If you go past the bolt hole you must start over again. To see if the No. 1 piston is on the compression stroke, remove the breather assembly from the valve cover and look at the valves of the No. 1 cylinder. The valves will be closed if No. 1 cylinder is on the compression stroke. You must be able to move the rocker arms up and down with your hand.7. If NO. 1 piston is not on the compression stroke, remove tooling (B) and turn the flywheel 360° counterclockwise. Install tooling (B). The No. 1 piston is now at top center on the compression stroke.8. With tooling (A) and (B) installed in position, install the timing advance weight assembly on the fuel pump camshaft. 9. Use tool (D) to hold the gear. Install tooling (C) on the weight assembly. While a constant torque on drive gear on 68 N m (50 lb ft) is held, tighten the bolt that fastens the weight assembly to fuel pump camshaft to a torque of 270 25 N m (200 18 lb ft).10. Remove tooling (A), (B) and (C).End By:a. install timing gear coverDisassemble And Assemble Automatic Timing Unit

Start By:a. remove automatic timing advance unit

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove two screws (1) and plate (2).

The weights are held on position with two springs for each weight under compression. Carefully remove weights and springs to prevent possible injury.

2. Remove springs (4) and (5), weight (3) and slide (6) from each side of assembly. 3. If necessary, remove gear (7). Remove

Weight assembly must have support during removal to prevent damage to components.

2. Install tooling (A) and remove the weight assembly.Install Automatic Timing Advance Unit

1. Install washer and bolt (1). With the fuel pump housing cover removed, turn the fuel pump camshaft in the direction of engine rotation until tool (A) can be installed in the notch of the camshaft. 2. To time the fuel injection pump to the engine with the front timing cover removed, follow Steps 3 and 4. With the timing cover installed, see Steps 6 and 7. No. 1 piston at top center (TC) on the compression stroke is the starting point for all timing procedures. The engine is seen from the flywheel end when direction of crankshaft rotation is given.3. Turn the crankshaft counterclockwise until the "C" on the crankshaft and camshaft and camshaft gears are in alignment. 4. Remove the plug and install tool (B) in the flywheel housing.5. To find top center compression stroke for No. 1 piston, turn the flywheel clockwise (opposite of engine rotation) approximately 30°. This procedure is to remove all end play from timing gears.6. Turn the flywheel counterclockwise (direction of engine rotation) until tool (B) can be installed in the flywheel. The piston is at top center. If you go past the bolt hole you must start over again. To see if the No. 1 piston is on the compression stroke, remove the breather assembly from the valve cover and look at the valves of the No. 1 cylinder. The valves will be closed if No. 1 cylinder is on the compression stroke. You must be able to move the rocker arms up and down with your hand.7. If NO. 1 piston is not on the compression stroke, remove tooling (B) and turn the flywheel 360° counterclockwise. Install tooling (B). The No. 1 piston is now at top center on the compression stroke.8. With tooling (A) and (B) installed in position, install the timing advance weight assembly on the fuel pump camshaft. 9. Use tool (D) to hold the gear. Install tooling (C) on the weight assembly. While a constant torque on drive gear on 68 N m (50 lb ft) is held, tighten the bolt that fastens the weight assembly to fuel pump camshaft to a torque of 270 25 N m (200 18 lb ft).10. Remove tooling (A), (B) and (C).End By:a. install timing gear coverDisassemble And Assemble Automatic Timing Unit

Start By:a. remove automatic timing advance unit

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove two screws (1) and plate (2).

The weights are held on position with two springs for each weight under compression. Carefully remove weights and springs to prevent possible injury.

2. Remove springs (4) and (5), weight (3) and slide (6) from each side of assembly. 3. If necessary, remove gear (7). Remove