Information injection-pump assembly

BOSCH

9 400 617 603

9400617603

ZEXEL

106682-9160

1066829160

KOMATSU

6166711530

6166711530

Rating:

Cross reference number

BOSCH

9 400 617 603

9400617603

ZEXEL

106682-9160

1066829160

KOMATSU

6166711530

6166711530

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15.7

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

395

390

400

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Remarks

Standard point A's rack position same as row R

Standard point A's rack position same as row R

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.1+-0.5

Pump speed

r/min

330

330

330

Average injection quantity

mm3/st.

31

26

36

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

R1-2.2

Boost pressure

kPa

13.3

10.6

16

Boost pressure

mmHg

100

80

120

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

R1(17.1)

Boost pressure

kPa

40

33.3

46.7

Boost pressure

mmHg

300

250

350

Test data Ex:

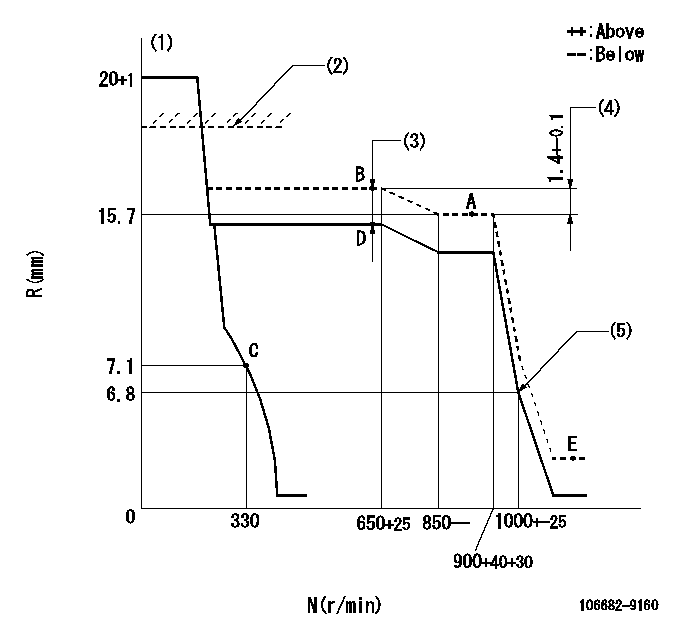

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL (set using 106684-4170)

(3)Boost compensator stroke: BCL

(4)Rack difference between N = N1 and N = N2

(5)Idle sub spring setting: L1.

----------

K=20 RAL=17.6+0.2mm BCL=2.2+-0.1mm N1=900r/min N2=650r/min L1=6.8-0.5mm

----------

----------

K=20 RAL=17.6+0.2mm BCL=2.2+-0.1mm N1=900r/min N2=650r/min L1=6.8-0.5mm

----------

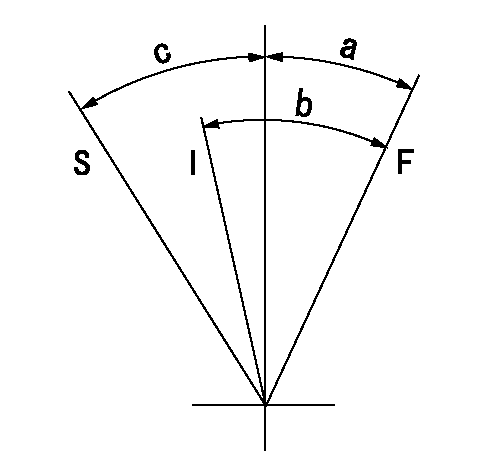

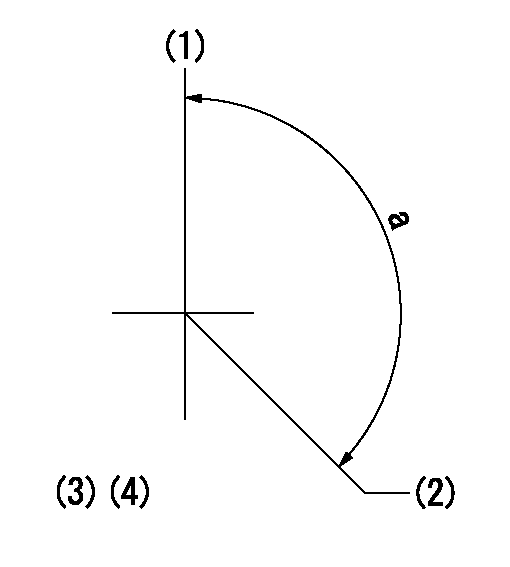

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=(19deg)+-5deg b=(31deg)+-5deg c=33deg+-3deg

----------

----------

a=(19deg)+-5deg b=(31deg)+-5deg c=33deg+-3deg

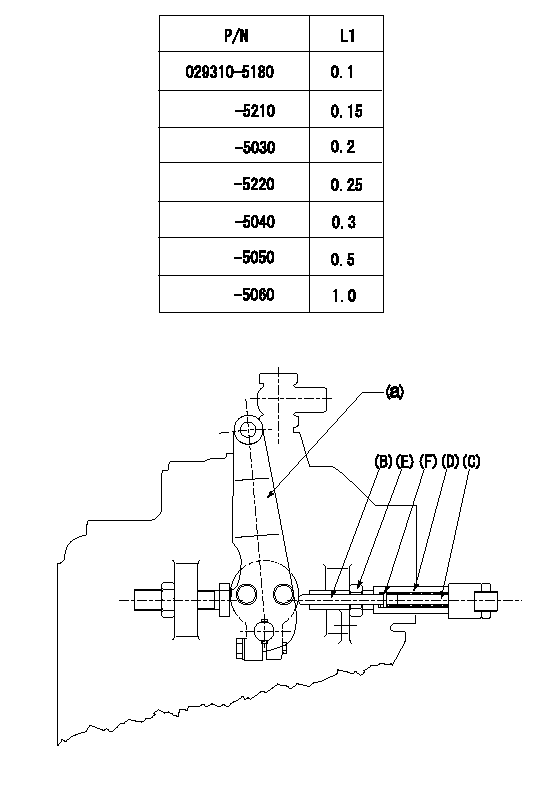

0000001501 LEVER

Speed lever adjustment

1. (1) For idling hold the speed lever (a) against the push rod (B).

(2)At this time, confirm that the spring (C) is not bent by the operating torque of the speed lever.

2. (1) To stop, bend the spring (C) using the speed lever.

(2)Set so that the rack position is L2.

(3)Set and fix using lock nut (E) so that it contacts the guide screw (D).

(4)Adjust rack position at this time using shim (F).

3. Confirm that the speed lever returns to the idling position when pulled in the stop direction and then released.

----------

L2=0.2~2mm

----------

----------

L2=0.2~2mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of spline gear's aligning mark at No 1 cylinder's beginning of injection (key position)

(3)B.T.D.C.: aa

(4)-

----------

aa=34deg

----------

a=(130deg)

----------

aa=34deg

----------

a=(130deg)

Information:

Fuel consumption complaints are related to engine owners expectations. They may often times be related to the engine itself, causes other than the engine, and in some cases the fuel consumption may be normal for the application. Only a good discussion with the owner/operator, as described in the "Owner/Operator Input" section, will give guidance as to a correct repair or to prevent unnecessary repairs.Owner/Operator Input

The following are some of the questions which should be asked before beginning any diagnosis or repair for an engine performance complaint. There Are No Hard And Fast Answers For These Questions. There are many factors that can cause poor fuel mileage or make users believe they are getting fuel-poor-mileage.There are also a variety of customer expectations which are acceptable. The answers to these questions will give you a better understanding and perspective on the complaint and may identify characteristics which will help pinpoint the cause of the complaint quickly. 1. Are miles measured accurately?A most common problem in determining mpg is errors in recording the number of miles traveled. A. Is this vehicle hub or cab odometer accurate?The easiest way to check an odometer is to install a hub odometer known to be accurate and for the tire size on the truck. Run the truck over several hundred miles and compare the reading with the original odometer.Odometers may also be checked by comparing them to interstate mile posts or by running over a course of known length - a 50-mile run is required to get a good check. B. Are "book miles" or "driver-paid miles" correct?Another way in which miles for mpg calculations are obtained by a fleet is the use of "book miles" or "driver-paid miles". The use of this system can short mileage accumulation by 10 to 15%; thus, mpg is low by 10 to 15%. C. Is the vehicle used for pick-up and delivery operation?Another problem affecting mileage accumulation in many fleets is the use of linehaul equipment for pickup and delivery operations. In the "book mile" system, the truck rarely gets credit for any miles run in pick-up and delivery. 2. Is fuel measurement accurate?There are a number of ways in which fuel measurement can be the source of mpg problems. A. Are fuel pumps calibrated?If fuel tickets come from company-owned fuel pumps, there can be errors because nonrevenue fuel pumps do not have calibration requirements in many states. B. Are road fuel tickets accurate?The only way to verify fuel additions when road fuel tickets are used is a laborious ticket-by-ticket audit ensuring that the correct amount of fuel has been entered for the vehicles in question and that there are no indications of incorrect entries. C. Are tank-full mileage checks correctly done?The big problem in "tank-full" checks is getting the tank filled to the same level before and after the user "checked the mileage". With two 100 gallon tanks, errors of 5 to 10 gallons are very common in topping off tanks because of the way truck tanks

The following are some of the questions which should be asked before beginning any diagnosis or repair for an engine performance complaint. There Are No Hard And Fast Answers For These Questions. There are many factors that can cause poor fuel mileage or make users believe they are getting fuel-poor-mileage.There are also a variety of customer expectations which are acceptable. The answers to these questions will give you a better understanding and perspective on the complaint and may identify characteristics which will help pinpoint the cause of the complaint quickly. 1. Are miles measured accurately?A most common problem in determining mpg is errors in recording the number of miles traveled. A. Is this vehicle hub or cab odometer accurate?The easiest way to check an odometer is to install a hub odometer known to be accurate and for the tire size on the truck. Run the truck over several hundred miles and compare the reading with the original odometer.Odometers may also be checked by comparing them to interstate mile posts or by running over a course of known length - a 50-mile run is required to get a good check. B. Are "book miles" or "driver-paid miles" correct?Another way in which miles for mpg calculations are obtained by a fleet is the use of "book miles" or "driver-paid miles". The use of this system can short mileage accumulation by 10 to 15%; thus, mpg is low by 10 to 15%. C. Is the vehicle used for pick-up and delivery operation?Another problem affecting mileage accumulation in many fleets is the use of linehaul equipment for pickup and delivery operations. In the "book mile" system, the truck rarely gets credit for any miles run in pick-up and delivery. 2. Is fuel measurement accurate?There are a number of ways in which fuel measurement can be the source of mpg problems. A. Are fuel pumps calibrated?If fuel tickets come from company-owned fuel pumps, there can be errors because nonrevenue fuel pumps do not have calibration requirements in many states. B. Are road fuel tickets accurate?The only way to verify fuel additions when road fuel tickets are used is a laborious ticket-by-ticket audit ensuring that the correct amount of fuel has been entered for the vehicles in question and that there are no indications of incorrect entries. C. Are tank-full mileage checks correctly done?The big problem in "tank-full" checks is getting the tank filled to the same level before and after the user "checked the mileage". With two 100 gallon tanks, errors of 5 to 10 gallons are very common in topping off tanks because of the way truck tanks