Information injection-pump assembly

BOSCH

9 400 617 544

9400617544

ZEXEL

106682-4280

1066824280

KUBOTA

1452603210

1452603210

Rating:

Service parts 106682-4280 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

26.0(265)

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106682-4280

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 544

9400617544

ZEXEL

106682-4280

1066824280

KUBOTA

1452603210

1452603210

Zexel num

Bosch num

Firm num

Name

106682-4280

9 400 617 544

1452603210 KUBOTA

INJECTION-PUMP ASSEMBLY

LH105CS * K

LH105CS * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

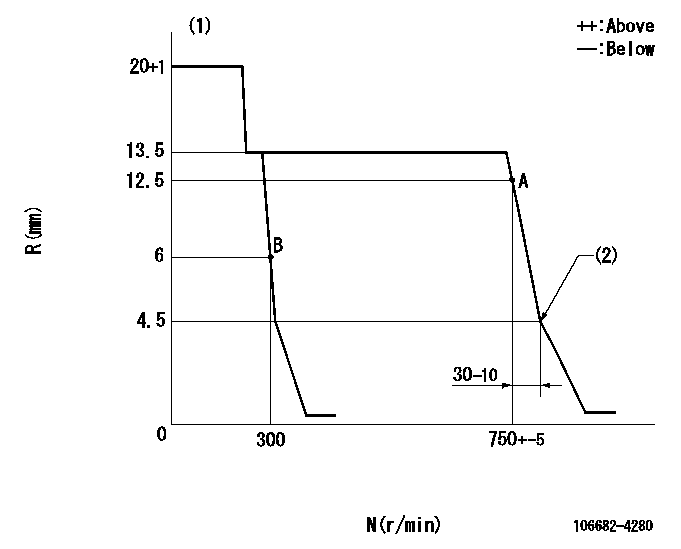

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

750

750

750

Each cylinder's injection qty

mm3/st.

305

298.3

311.7

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6+-0.5

Pump speed

r/min

300

300

300

Each cylinder's injection qty

mm3/st.

30

25.5

34.5

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Idle sub spring setting: L1.

----------

K=11 L1=4.5-0.5mm

----------

----------

K=11 L1=4.5-0.5mm

----------

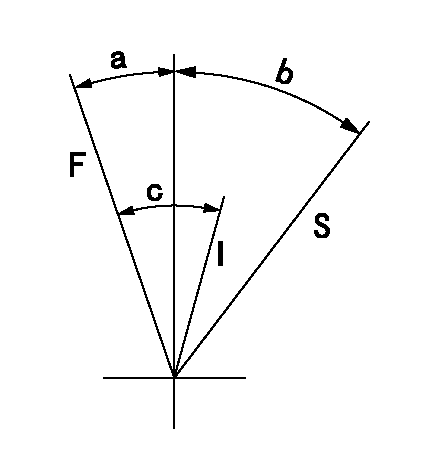

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=13deg+-5deg b=32deg+-5deg c=28.5deg+-5deg

----------

----------

a=13deg+-5deg b=32deg+-5deg c=28.5deg+-5deg

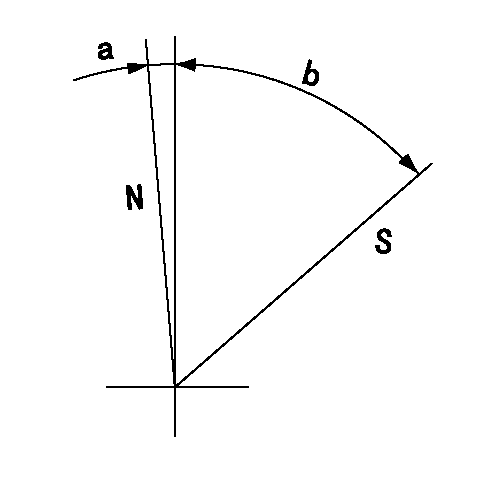

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(0deg) b=(53deg)

----------

----------

a=(0deg) b=(53deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Bolts And Bolt Torque

A bolt which is too long may "bottom" before the head is tight against the part it is to hold. The threads can be damaged when a "long" bolt is removed.If a bolt is too short, there may not be enough threads engaged to hold the part securely.Apply proper torque values to all bolts and nuts when assembling Caterpillar equipment. When a specific torque value is required, the value is listed in the SPECIFICATIONS section of the Service Manual. Tighten all other bolts and nuts for general usage, hydraulic valve bodies, or taperlock studs to the torque values given in the torque charts.T-T-T Procedure

A torque-turn-tighten (T-T-T) procedure is used in many specifications and instructions.1. Clean the bolt and nut threads.2. Put lubricant on the threads and the seat face of the bolt and the nut.3. Turn the bolt or the nut tight according to the torque specification.4. Put a location mark on the part and on the bolt or the nut.5. Turn the bolt or the nut tighter the amount of degrees according to the specifications. The side of a nut or bolt head can be used for reference if a mark can not be put on. Torque Wrench Extension

When a torque wrench extension is used with a torque wrench, the torque indication on the torque wrench will be less than the real torque.

TORQUE WRENCH WITH TORQUE WRENCH EXTENSION

E: Torque wrench drive axis-to-torque wrench extension drive axis. W: Mark on handle-to-torque wrench drive axis.1. Put a mark on the handle. Measure the handle from the mark to the axis of the torque wrench drive (W).2. Measure the torque wrench extension from the torque wrench drive to the axis of the torque wrench extension drive (E).3. To get correct torque indication (TI) when the real torque (RT) is known: Example: W = 12 in. (304.8 mm); E = 2.56 in. (65.0 mm); RT (from specifications) = 125 lb. ft. (170 N m). 4. Hold the torque wrench handle with the longest finger of the hand over the mark on the handle to get the real torque (RT) with low torque indication (TI) on the torque wrench.Locks

Flat metal locks must be installed properly to be effective. Bend one end of the lock around the edge of the part. Bend the other end against one flat surface of the nut or bolt head.Always install new locks in compartments which house moving parts.If lockwashers are installed on housings made of aluminum, use a flat washer between the lockwasher and the housing. Lines And Wires

When removing or disconnecting a group of lines or wires, tag each one to assure proper assembly.Lubrication

Where applicable, fill the compartments of the components serviced with the amount, type and grade of lubricant recommended in the Lubrication and Maintenance Guide.Rust Preventive Compound

Clean the rust preventive compound from all machined surfaces of new parts before installing them.Shims

When shims are removed, tie them together and identify them as to location. Keep shims clean and flat until they are

A bolt which is too long may "bottom" before the head is tight against the part it is to hold. The threads can be damaged when a "long" bolt is removed.If a bolt is too short, there may not be enough threads engaged to hold the part securely.Apply proper torque values to all bolts and nuts when assembling Caterpillar equipment. When a specific torque value is required, the value is listed in the SPECIFICATIONS section of the Service Manual. Tighten all other bolts and nuts for general usage, hydraulic valve bodies, or taperlock studs to the torque values given in the torque charts.T-T-T Procedure

A torque-turn-tighten (T-T-T) procedure is used in many specifications and instructions.1. Clean the bolt and nut threads.2. Put lubricant on the threads and the seat face of the bolt and the nut.3. Turn the bolt or the nut tight according to the torque specification.4. Put a location mark on the part and on the bolt or the nut.5. Turn the bolt or the nut tighter the amount of degrees according to the specifications. The side of a nut or bolt head can be used for reference if a mark can not be put on. Torque Wrench Extension

When a torque wrench extension is used with a torque wrench, the torque indication on the torque wrench will be less than the real torque.

TORQUE WRENCH WITH TORQUE WRENCH EXTENSION

E: Torque wrench drive axis-to-torque wrench extension drive axis. W: Mark on handle-to-torque wrench drive axis.1. Put a mark on the handle. Measure the handle from the mark to the axis of the torque wrench drive (W).2. Measure the torque wrench extension from the torque wrench drive to the axis of the torque wrench extension drive (E).3. To get correct torque indication (TI) when the real torque (RT) is known: Example: W = 12 in. (304.8 mm); E = 2.56 in. (65.0 mm); RT (from specifications) = 125 lb. ft. (170 N m). 4. Hold the torque wrench handle with the longest finger of the hand over the mark on the handle to get the real torque (RT) with low torque indication (TI) on the torque wrench.Locks

Flat metal locks must be installed properly to be effective. Bend one end of the lock around the edge of the part. Bend the other end against one flat surface of the nut or bolt head.Always install new locks in compartments which house moving parts.If lockwashers are installed on housings made of aluminum, use a flat washer between the lockwasher and the housing. Lines And Wires

When removing or disconnecting a group of lines or wires, tag each one to assure proper assembly.Lubrication

Where applicable, fill the compartments of the components serviced with the amount, type and grade of lubricant recommended in the Lubrication and Maintenance Guide.Rust Preventive Compound

Clean the rust preventive compound from all machined surfaces of new parts before installing them.Shims

When shims are removed, tie them together and identify them as to location. Keep shims clean and flat until they are

Have questions with 106682-4280?

Group cross 106682-4280 ZEXEL

Kubota

106682-4280

9 400 617 544

1452603210

INJECTION-PUMP ASSEMBLY

LH105CS

LH105CS