Information injection-pump assembly

BOSCH

F 019 Z20 171

f019z20171

ZEXEL

106681-4460

1066814460

NIIGATA-TEKKOU

75L47530A

75l47530a

Rating:

Service parts 106681-4460 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

25.5{260}

15.

NOZZLE SET

Include in #1:

106681-4460

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z20 171

f019z20171

ZEXEL

106681-4460

1066814460

NIIGATA-TEKKOU

75L47530A

75l47530a

Zexel num

Bosch num

Firm num

Name

F 019 Z20 171

75L47530A NIIGATA-TEKKOU

INJECTION-PUMP ASSEMBLY

DMF13HZA * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

DMF13HZA * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(14.3)

Vist

V

1.71

1.71

1.71

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

204

199

209

Max. variation between cylinders

%

0

-3

3

Basic

*

Injection quantity adjustment_02

Rack position

(5.6)

Vist

V

3.01

2.91

3.11

Pump speed

r/min

330

330

330

Average injection quantity

mm3/st.

18

16.5

19.5

Max. variation between cylinders

%

0

-8

8

Governor adjustment

Pump speed

r/min

390--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

340

Advance angle

deg.

0.5

Governor adjustment_03

Pump speed

r/min

660

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

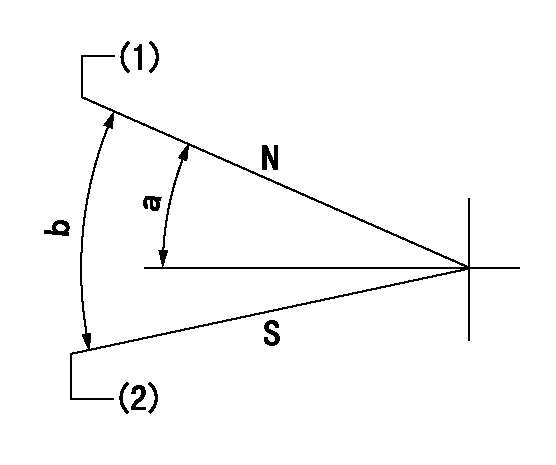

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=18.2+0.3mm bb=1mm

----------

a=23.5deg+-5deg b=33.5deg+-5deg

----------

aa=18.2+0.3mm bb=1mm

----------

a=23.5deg+-5deg b=33.5deg+-5deg

0000000901

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(5deg)

----------

aa=16deg

----------

a=(5deg)

Stop lever angle

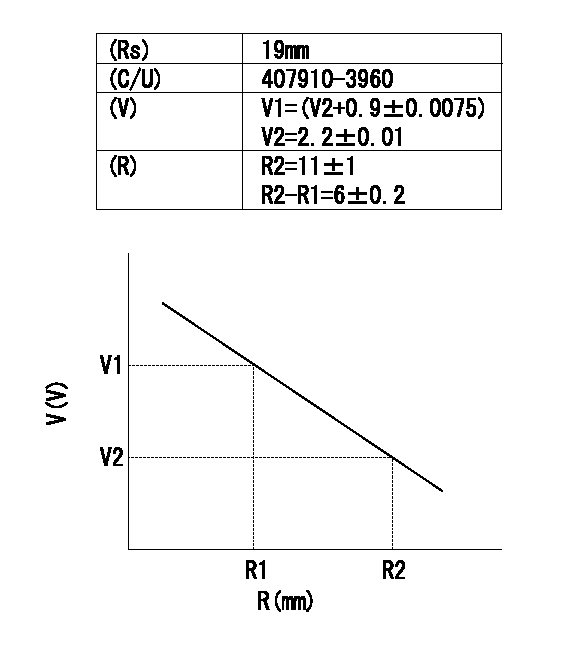

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

Install the pump cover onto the pump housing. Tighten the four middle bolts. Then, tighten the end bolts in a crisscross pattern. Tighten the bolts to a torque of 10.2 N m (90 lb in).Note: Make sure that the gasket is in place between the housing and the cover.

Repeat Step 1 and Step 2 in order to confirm the electrical connection for the pump coil was not damaged during the removal of the pump cover.

Install the oil inlet line adapter, inlet line, and harness connector to the pump.Note: After the HEUI pump is replaced or reassembled, the engine must be cranked for an extended length of time to fill the pump with oil.Note: Clear any diagnostic or event codes that activated during the initial start-up.

If the engine would not start before inspecting for debris and no debris was found in the HEUI pump, return to Step D in the diagnostic flow chart.If the engine would start before inspecting for debris and no debris was found in the HEUI pump, return to Step L in the diagnostic flow chart.If the pump is to be replaced, complete the checklist form in Special Instruction, REHS5031 that is provided with the service replacement part and insert the completed form back into the box containing the part that is being returned. Proceed to the section of this instruction titled "Oil Rail Cleaning Procedure" for the correct engine size that is being serviced.Oil Rail Cleaning Procedure For the C7 Engine

Illustration 12 g02702636

C7 Cylinder Head

Illustration 13 g02708256

The oil and fuel passages are the same for both the C7 and C9.

(6) Oil Rail for a HEUI fuel system

(7) Oil passage to injector bore

(8) Fuel passage

(9) Injector bore Note: Contain any oil and cleaner that will flow from the cylinder and the lines during the following process. Properly dispose of the oil and contaminated cleaner when work is complete.

Remove fuel injectors. Refer to Disassembly and Assembly for specific machine.

Install six plugs 9U-7080 Tapered Cap/Plug into the lower injector bores. The plugs will prevent oil, cleaners, and debris from entering the cylinders.

Remove the plugs from the front and rear of the cylinder head main oil gallery

Remove the pressure sensor from the cylinder head. Protect the sensor.

Clean out the two rail drain holes by removing their plugs and using the brake cleaner and long squirting straw to flush these passages to the oil rail.

Using the solvent gun with and without the