Information injection-pump assembly

ZEXEL

106681-4451

1066814451

YANMAR

12788151980

12788151980

Rating:

Cross reference number

ZEXEL

106681-4451

1066814451

YANMAR

12788151980

12788151980

Zexel num

Bosch num

Firm num

Name

106681-4451

12788151980 YANMAR

INJECTION-PUMP ASSEMBLY

6CZ-GT K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6CZ-GT K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

14.9

Pump speed

r/min

1150

1150

1150

Each cylinder's injection qty

mm3/st.

424

411.3

436.7

Basic

*

Fixing the lever

*

Boost pressure

kPa

112

112

Boost pressure

mmHg

840

840

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.2+-0.5

Pump speed

r/min

250

250

250

Each cylinder's injection qty

mm3/st.

21.5

18.3

24.7

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

15.1++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

460

450

470

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-2.8

Boost pressure

kPa

52

49.3

54.7

Boost pressure

mmHg

390

370

410

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(14.9)

Boost pressure

kPa

98.6

91.9

105.3

Boost pressure

mmHg

740

690

790

Timer adjustment

Pump speed

r/min

480--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

430

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

620

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

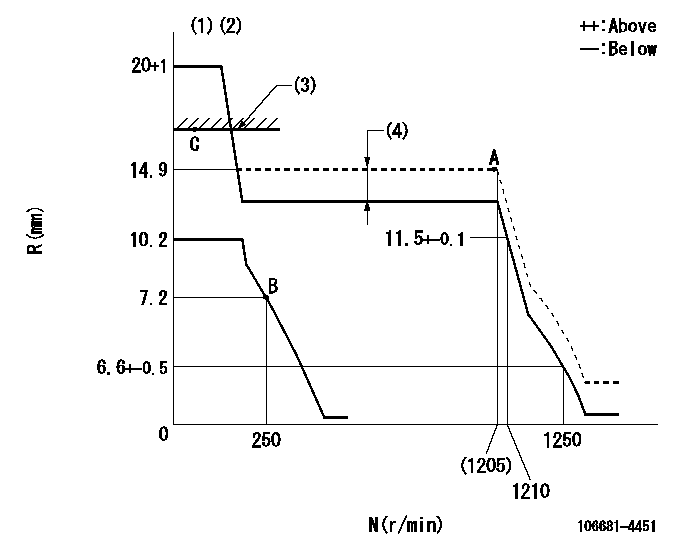

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

K=6 BCL=2.8+-0.1mm

----------

----------

K=6 BCL=2.8+-0.1mm

----------

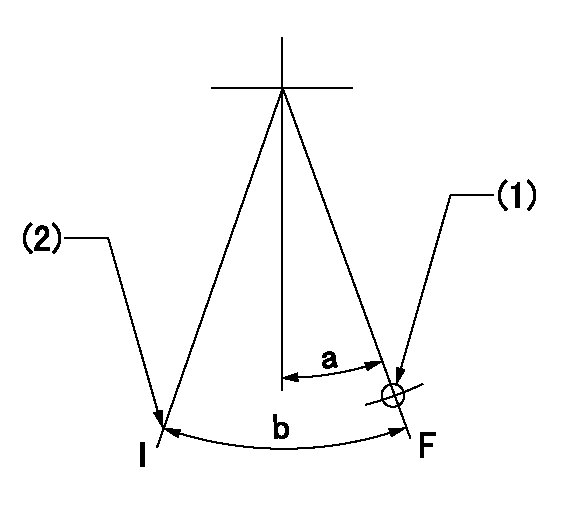

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=100r/min

----------

a=12deg+-5deg b=37deg+-5deg

----------

aa=100r/min

----------

a=12deg+-5deg b=37deg+-5deg

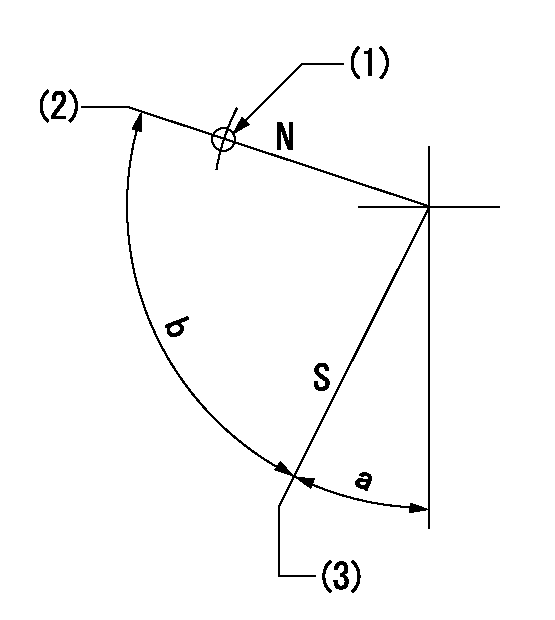

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Normal

(3)Rack position bb, pump speed cc (seal at delivery)

----------

aa=20mm bb=1-0.5mm cc=0r/min

----------

a=37deg+-5deg b=(73deg)

----------

aa=20mm bb=1-0.5mm cc=0r/min

----------

a=37deg+-5deg b=(73deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Introduction

Do not perform any procedure that is outlined in the Special Instruction until the entire instruction has been read and understood.Check Valve Torque

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

The check valves that are located within the fuel pressure regulator group are sensitive to assembly torque. In order to eliminate the risk of valve distortion, torque the check valves to 28 3 N m (21 2 lb ft). Refer to Table 1 for the check valve part numbers that required the torque that is listed above.

Table 1

Part Number Description

327-0376 Check Valve Gp

327-4448 Check Valve Gp

281-2725 Check Valve Gp

282-1915 Check Valve Gp

228-7381 Check Valve Gp

327-8044 Check Valve Gp

Do not perform any procedure that is outlined in the Special Instruction until the entire instruction has been read and understood.Check Valve Torque

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

The check valves that are located within the fuel pressure regulator group are sensitive to assembly torque. In order to eliminate the risk of valve distortion, torque the check valves to 28 3 N m (21 2 lb ft). Refer to Table 1 for the check valve part numbers that required the torque that is listed above.

Table 1

Part Number Description

327-0376 Check Valve Gp

327-4448 Check Valve Gp

281-2725 Check Valve Gp

282-1915 Check Valve Gp

228-7381 Check Valve Gp

327-8044 Check Valve Gp

Have questions with 106681-4451?

Group cross 106681-4451 ZEXEL

Mitsubishi-Heav

Mitsubishi-Heav

Yanmar

106681-4451

12788151980

INJECTION-PUMP ASSEMBLY

6CZ-GT

6CZ-GT