Information injection-pump assembly

ZEXEL

106681-4380

1066814380

MITSUBISHI-HEAV

35A6500180

35a6500180

Rating:

Cross reference number

ZEXEL

106681-4380

1066814380

MITSUBISHI-HEAV

35A6500180

35a6500180

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

13

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

368

359

377

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

61.3

61.3

Boost pressure

mmHg

460

460

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.8+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

28.5

25.5

31.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

440

420

460

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

575

575

575

Rack position

R1-1.5

Boost pressure

kPa

30.7

28

33.4

Boost pressure

mmHg

230

210

250

Boost compensator adjustment_02

Pump speed

r/min

575

575

575

Rack position

R1(13)

Boost pressure

kPa

48

41.3

54.7

Boost pressure

mmHg

360

310

410

Timer adjustment

Pump speed

r/min

[N1+50]-

-

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

4

3.5

4.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

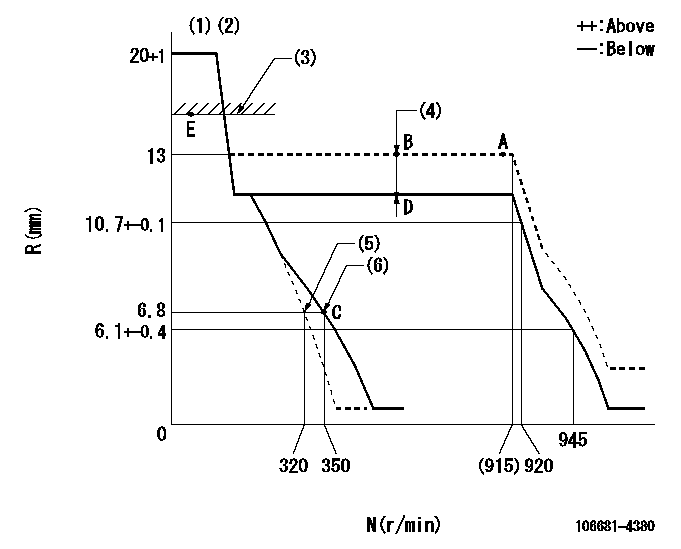

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

(5)Main spring setting

(6)Set idle sub-spring

----------

K=10 BCL=1.5+-0.1mm

----------

----------

K=10 BCL=1.5+-0.1mm

----------

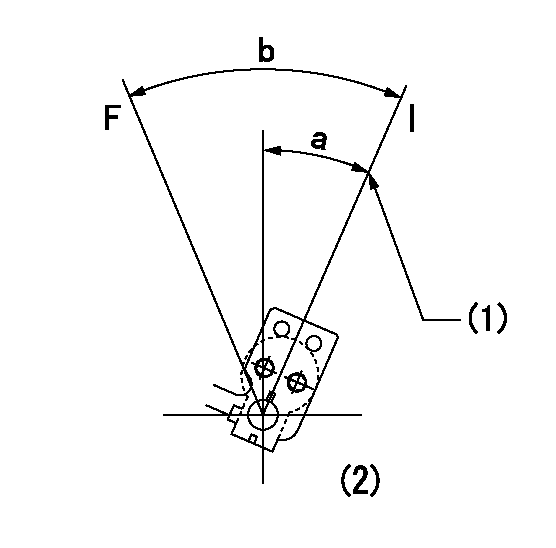

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At the center of the lever key groove

----------

----------

a=26deg+-5deg b=26deg+-5deg

----------

----------

a=26deg+-5deg b=26deg+-5deg

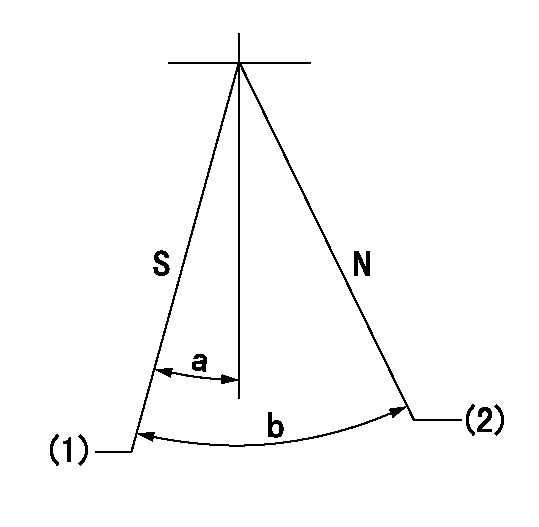

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa, rack position bb

(2)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=33deg+-5deg b=(73deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=33deg+-5deg b=(73deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

2. Remove the turbocharger outlet pipe (1) and elbow from the aftercooler and turbocharger as a unit. Cover the openings to keep dirt and foreign material out of the engine.3. Remove breather tube (2) from the engine.4. Disconnect tube assembly (3) from the aftercooler. 5. Remove vent tube (4) from the engine.6. Remove cover (5) from the aftercooler and remove the two O-ring seals from the cover.7. Loosen the clamps on hose (7) and remove tube assembly (6) from the hose and aftercooler. Remove the O-ring seal from the tube assembly. 8. Remove collar (10) and the gasket. Remove the O-ring seal from the collar.9. Remove bolts (9) and remove cover (8). 10. Remove elbow (12) and the gaskets from the engine. Remove aftercooler core assembly (11). Remove the O-ring seals from the core assembly. 11. Remove bolts (13), housing (14) and the gasket from the cylinder head.Install Aftercooler

1. Put the gasket and housing (1) in position on the cylinder head and install the bolts that hold it. 2. Install the gaskets, adapter and elbow (3).3. Put the O-ring seals on core assembly (2) and install core assembly (2) and the gaskets in the housing. 4. Put the O-ring seal on collar (5) and install the gasket and collar in the housing.5. Put the gasket and cover (4) in position on the housing and install the bolts that hold it. 6. Put the O-ring seals on cover (6) and install the gasket and cover. Install vent tube (7).7. Install the O-ring seal on tube assembly (8) and install the gasket and tube assembly (8). 8. Connect tube assembly (11) to the aftercooler housing.9. Install breather tube (10).10. Put the O-ring seals on pipe (9) and install the pipe, elbow and gasket.11. Fill the cooling system with coolant to the correct level.

1. Put the gasket and housing (1) in position on the cylinder head and install the bolts that hold it. 2. Install the gaskets, adapter and elbow (3).3. Put the O-ring seals on core assembly (2) and install core assembly (2) and the gaskets in the housing. 4. Put the O-ring seal on collar (5) and install the gasket and collar in the housing.5. Put the gasket and cover (4) in position on the housing and install the bolts that hold it. 6. Put the O-ring seals on cover (6) and install the gasket and cover. Install vent tube (7).7. Install the O-ring seal on tube assembly (8) and install the gasket and tube assembly (8). 8. Connect tube assembly (11) to the aftercooler housing.9. Install breather tube (10).10. Put the O-ring seals on pipe (9) and install the pipe, elbow and gasket.11. Fill the cooling system with coolant to the correct level.