Information injection-pump assembly

BOSCH

9 400 612 430

9400612430

ZEXEL

106681-4371

1066814371

YANMAR

12862451000

12862451000

Rating:

Service parts 106681-4371 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106681-4371

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 612 430

9400612430

ZEXEL

106681-4371

1066814371

YANMAR

12862451000

12862451000

Zexel num

Bosch num

Firm num

Name

106681-4371

9 400 612 430

12862451000 YANMAR

INJECTION-PUMP ASSEMBLY

6GHA-ET K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6GHA-ET K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.1

4.05

4.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.9

Pump speed

r/min

1175

1175

1175

Each cylinder's injection qty

mm3/st.

349

338.5

359.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

98.6

98.6

Boost pressure

mmHg

740

740

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

15

13.5

16.5

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

285

285

305

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-0.85

Boost pressure

kPa

37.3

34.6

40

Boost pressure

mmHg

280

260

300

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(12.9)

Boost pressure

kPa

85.3

85.3

85.3

Boost pressure

mmHg

640

640

640

Timer adjustment

Pump speed

r/min

400--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

350

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

520

Advance angle

deg.

1

0.7

1.3

Remarks

Finish

Finish

Test data Ex:

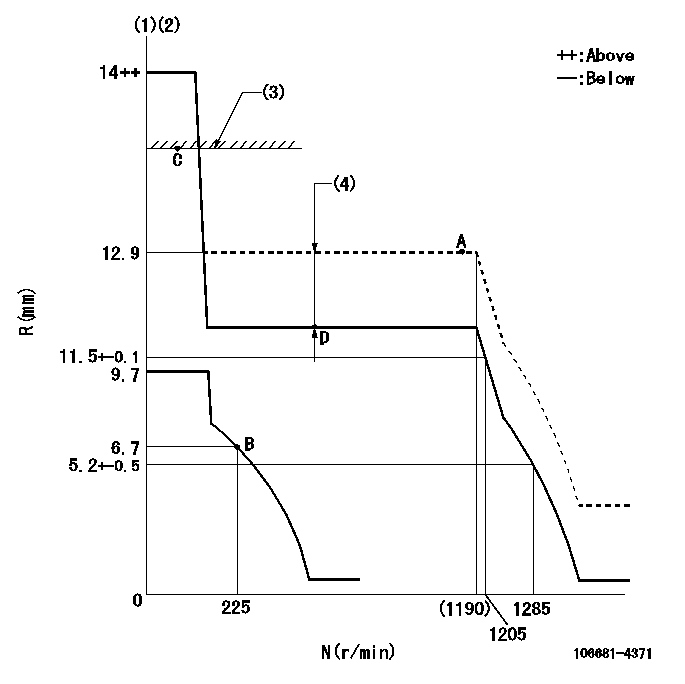

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

K=7 BCL=0.85+-0.1mm

----------

----------

K=7 BCL=0.85+-0.1mm

----------

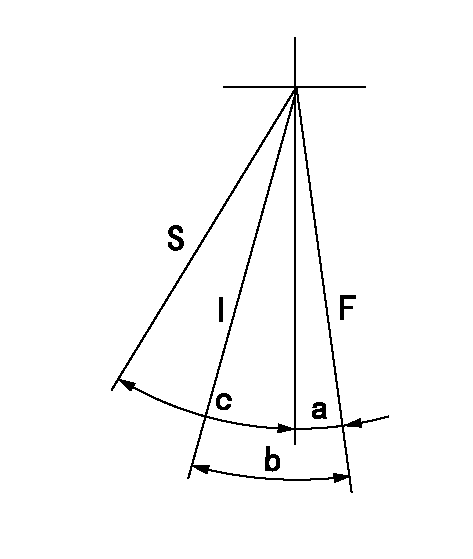

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=10deg+-5deg b=33deg+-5deg c=35deg+-3deg

----------

----------

a=10deg+-5deg b=33deg+-5deg c=35deg+-3deg

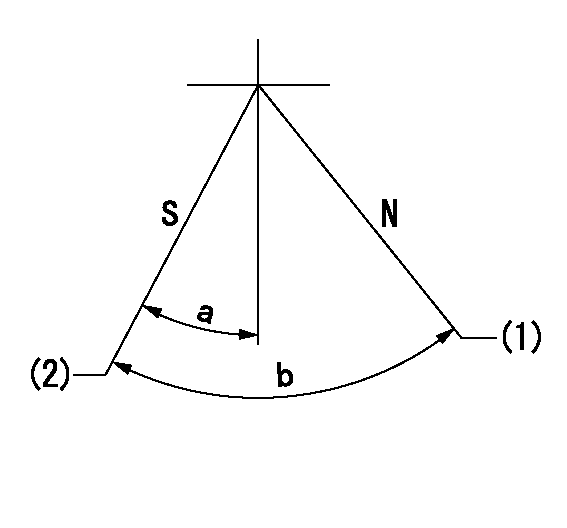

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed aa, rack position bb

----------

aa=0r/min bb=1-0.5mm

----------

a=25deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=25deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

8. Remove O-ring seal (10), the thrust washer and the bearing from the adapter with tool (A).9. Remove bolts (12) from the cover. Remove cover (11) and the gasket from the crankcase. 10. Bend down the lock on lock straps (13). Remove bolts (14) from the bearing caps.11. Put identification on the bearing caps for correct installation with the connecting rod. Remove the bearing caps. 12. Remove pistons (15) from the crankcase through the top of the cylinders.13. Remove crankshaft (16) from the crankcase. Remove the key from the crankshaft. 14. Remove end cover (17) from the crankcase. Remove the O-ring seal, the thrust washer and the bearing.15. Remove cover (18), the gasket and the strainer from the air inlet opening. 16. Remove inlet valves (20) from their guides (21). Remove the inlet valve guides from around the inlet valve seats.

Be careful not to cause damage to the inlet valve seats.

17. Remove (unloader) spring (19), spring saddle (22) and the spring seat from the housing with needle nose pliers. 18. Remove (unloader) plunger (24) and guides (25) from the housing. Remove the guides from the plungers to plungers.19. To remove (unloader) pistons (23) from the bore, put a cover over the inlet port, then blow air pressure in the governor mounting pad (unloader) port. 20. Remove lockpin (27) that holds rod pin (26) in the piston. Remove the pin from connecting rod (28). 21. Remove the piston rings from piston (30). Remove two compression rings (29), the oil ring and the expander ring with tool (B).22. Remove the bearings from the connecting rod and the connecting rod cap. 23. Remove the piston pin bushing with tool (C).24. Remove the small seal rings from both ends of the housing.25. Clean all the oil passages through the housing, the crankshaft, the end cover and the adapter. Assemble Air Compressor

1. Check (unloader) bore bushings (1) for damage and wear. If these bushings need replacement, remove the bushing by the use of a 1/8 in. (3.18 mm) pipe threaded tap. Then install a 1/8 in. (3.18 mm) pipe threaded rod and pull the bushing straight up and out.2. Check the cylinder bores in the crankcase housing for damages (scored or out of round). Measure the cylinder bore in several places. If the measurement difference is more than .001 in. (0.03 mm) or taper is more than .002 (0.05 mm), the cylinder bore must be made larger (rebored or honed oversize). See SPECIFICATIONS.3. Install seal rings (3) in both ends of the crankcase housing.4. Install the new (unloader) pistons in their bore.

Be careful not to cause damage to the O-ring seals or the spiral rings.

5. Put the unloader plungers in their guides. Install the plunger and guide as a unit (6) to the crankcase housing and on top of the pistons. Install the unloader spring seat in the crankcase housing. 6. Put saddle (4) in position between the unloader piston guides. Install (unloader) spring (8). Make sure it makes a seat on the

Be careful not to cause damage to the inlet valve seats.

17. Remove (unloader) spring (19), spring saddle (22) and the spring seat from the housing with needle nose pliers. 18. Remove (unloader) plunger (24) and guides (25) from the housing. Remove the guides from the plungers to plungers.19. To remove (unloader) pistons (23) from the bore, put a cover over the inlet port, then blow air pressure in the governor mounting pad (unloader) port. 20. Remove lockpin (27) that holds rod pin (26) in the piston. Remove the pin from connecting rod (28). 21. Remove the piston rings from piston (30). Remove two compression rings (29), the oil ring and the expander ring with tool (B).22. Remove the bearings from the connecting rod and the connecting rod cap. 23. Remove the piston pin bushing with tool (C).24. Remove the small seal rings from both ends of the housing.25. Clean all the oil passages through the housing, the crankshaft, the end cover and the adapter. Assemble Air Compressor

1. Check (unloader) bore bushings (1) for damage and wear. If these bushings need replacement, remove the bushing by the use of a 1/8 in. (3.18 mm) pipe threaded tap. Then install a 1/8 in. (3.18 mm) pipe threaded rod and pull the bushing straight up and out.2. Check the cylinder bores in the crankcase housing for damages (scored or out of round). Measure the cylinder bore in several places. If the measurement difference is more than .001 in. (0.03 mm) or taper is more than .002 (0.05 mm), the cylinder bore must be made larger (rebored or honed oversize). See SPECIFICATIONS.3. Install seal rings (3) in both ends of the crankcase housing.4. Install the new (unloader) pistons in their bore.

Be careful not to cause damage to the O-ring seals or the spiral rings.

5. Put the unloader plungers in their guides. Install the plunger and guide as a unit (6) to the crankcase housing and on top of the pistons. Install the unloader spring seat in the crankcase housing. 6. Put saddle (4) in position between the unloader piston guides. Install (unloader) spring (8). Make sure it makes a seat on the

Have questions with 106681-4371?

Group cross 106681-4371 ZEXEL

Mitsubishi-Heav

Niigata-Urawa

Mitsubishi-Heav

Yanmar

Yanmar

Mitsubishi-Heav

Komatsu

Mitsubishi-Heav

Yanmar

106681-4371

9 400 612 430

12862451000

INJECTION-PUMP ASSEMBLY

6GHA-ET

6GHA-ET