Information injection-pump assembly

ZEXEL

106681-4340

1066814340

MITSUBISHI-HEAV

35A6500170

35a6500170

Rating:

Cross reference number

ZEXEL

106681-4340

1066814340

MITSUBISHI-HEAV

35A6500170

35a6500170

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

523

514

532

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Remarks

Point A is the same rack position as standard point (point A) for 106689-4060.

Point A is the same rack position as standard point (point A) for 106689-4060.

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.7+-0.5

Pump speed

r/min

310

310

310

Average injection quantity

mm3/st.

19.5

16.5

22.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

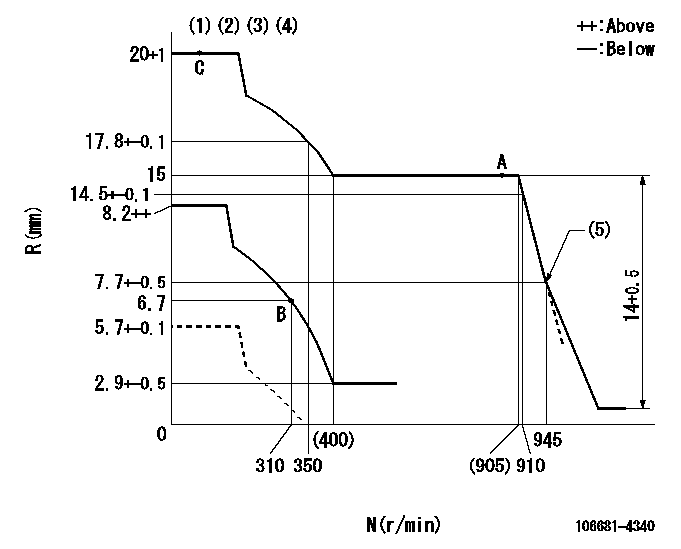

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Minimum - maximum speed specification

(2)Adjust at speed lever's full position.

(3)Target notch: K

(4)Tolerance for racks not indicated: +-0.05mm.

(5)Idle sub spring setting: L1.

----------

K=14 L1=7.7-0.5mm

----------

----------

K=14 L1=7.7-0.5mm

----------

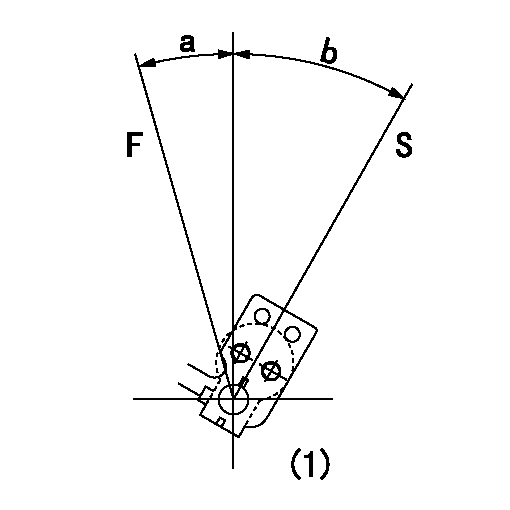

Speed control lever angle

F:Full speed

S:Stop

(1)At the center of the lever key groove

----------

----------

a=16deg+-5deg b=32deg+-3deg

----------

----------

a=16deg+-5deg b=32deg+-3deg

0000000901

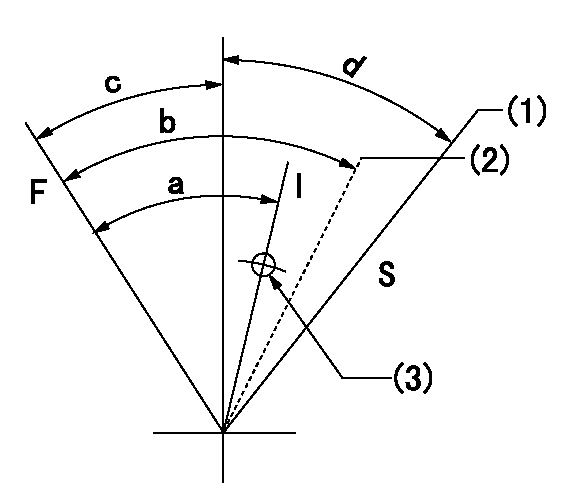

F:Full load

I:Idle

S:Stop

(1)Stop side boss position

(2)Pump speed aa, rack position bb

(3)Use the screw above R = cc

----------

aa=0r/min bb=5.7+-0.1mm cc=60mm

----------

a=25deg+-5deg b=38deg+-5deg c=19deg+-5deg d=30deg+-5deg

----------

aa=0r/min bb=5.7+-0.1mm cc=60mm

----------

a=25deg+-5deg b=38deg+-5deg c=19deg+-5deg d=30deg+-5deg

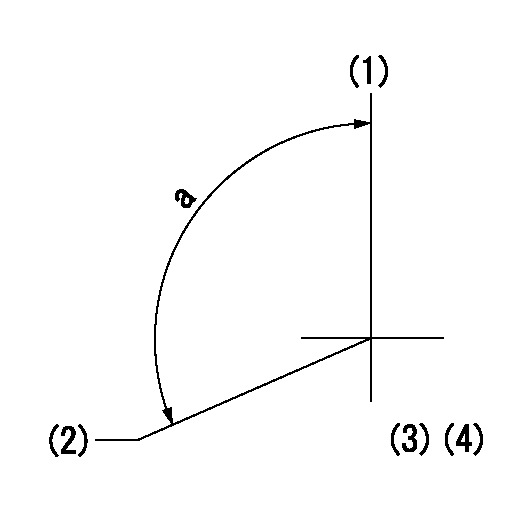

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(110deg)

----------

----------

a=(110deg)

Information:

start by: a) remove flywheel housingb) remove timing gear coverc) remove pistons 1. Turn the crankshaft until the "C" mark on crankshaft gear (2) is in alignment with the "C" mark on camshaft gear (1). 2. Put a mark across the teeth of the fuel pump drive gear and idler gear at location (X). Put a mark across the teeth of the idler gear and camshaft gear at location (Y). The marks are necessary for the correct timing of the camshaft for the fuel injection pump when the crankshaft is installed.3. Fasten a hoist to the crankshaft.4. Remove the caps for the crankshaft main bearings.5. Remove the crankshaft. Weight of the crankshaft is 200 lb. (91 kg).6. Remove the main bearings from the main bearing caps. Remove the crankshaft main bearings from the cylinder block. 7. Use tool (A) to remove the crankshaft gear and the oil seal wear sleeve.Install Crankshaft

1. Clean the bearing surfaces in the cylinder block. Install the upper halves of the main bearings in the block. Put clean SAE 30 engine oil on the bearings.2. Heat the crankshaft gear to a maximum temperature of 601°F (316°C). Install the gear on the crankshaft. Fasten a hoist to the crankshaft and put the crankshaft in position in the cylinder block with all timing marks in alignment.3. Clean the bearing surfaces of the main bearing caps. Install the lower halves of the main bearings in the caps. 4. Install Plastigage (A) on the bearing to check the bearing clearance. See INSTALL CRANKSHAFT MAIN BEARINGS for the correct bearing clearance procedure. The main bearing caps must be installed with the part number toward the front of the block. Make sure the number on the cap is the same number as the number on the left side of each cap saddle. 5. Install thrust plate (1) (bearing) in the No. 7 main bearing. The thrust bearing has a tab that fits into a machined area in the cylinder block. The tab will not let the thrust bearing be installed backward.6. Put clean SAE 30 engine oil on the cap bolt threads, face of the washers and lower halves of the main bearings. Put the caps in position on the engine. Install the bolts and washers. Tighten the bolts to a torque of 30 3 lb.ft. (40 4 N m). Put a mark across the bolt heads and bearing, and tighten the bolts 90° clockwise from the mark. 7. Check the crankshaft end play with tool group (B). End play with new bearings must be .0025 to .0145 in. (0.064 to 0.368 mm). Maximum permissible end play with used bearings is .025 in. (0.64 mm). The crankshaft end play is controlled by the thrust plates (bearings).8. If the fuel pump drive gear, idler gear, or camshaft gear has been removed or if a replacement of the crankshaft gear has been made, it will be necessary to put the engine into time after assembly. See INSTALL FUEL INJECTION PUMP

1. Clean the bearing surfaces in the cylinder block. Install the upper halves of the main bearings in the block. Put clean SAE 30 engine oil on the bearings.2. Heat the crankshaft gear to a maximum temperature of 601°F (316°C). Install the gear on the crankshaft. Fasten a hoist to the crankshaft and put the crankshaft in position in the cylinder block with all timing marks in alignment.3. Clean the bearing surfaces of the main bearing caps. Install the lower halves of the main bearings in the caps. 4. Install Plastigage (A) on the bearing to check the bearing clearance. See INSTALL CRANKSHAFT MAIN BEARINGS for the correct bearing clearance procedure. The main bearing caps must be installed with the part number toward the front of the block. Make sure the number on the cap is the same number as the number on the left side of each cap saddle. 5. Install thrust plate (1) (bearing) in the No. 7 main bearing. The thrust bearing has a tab that fits into a machined area in the cylinder block. The tab will not let the thrust bearing be installed backward.6. Put clean SAE 30 engine oil on the cap bolt threads, face of the washers and lower halves of the main bearings. Put the caps in position on the engine. Install the bolts and washers. Tighten the bolts to a torque of 30 3 lb.ft. (40 4 N m). Put a mark across the bolt heads and bearing, and tighten the bolts 90° clockwise from the mark. 7. Check the crankshaft end play with tool group (B). End play with new bearings must be .0025 to .0145 in. (0.064 to 0.368 mm). Maximum permissible end play with used bearings is .025 in. (0.64 mm). The crankshaft end play is controlled by the thrust plates (bearings).8. If the fuel pump drive gear, idler gear, or camshaft gear has been removed or if a replacement of the crankshaft gear has been made, it will be necessary to put the engine into time after assembly. See INSTALL FUEL INJECTION PUMP