Information injection-pump assembly

ZEXEL

106681-4222

1066814222

Rating:

Cross reference number

ZEXEL

106681-4222

1066814222

Zexel num

Bosch num

Firm num

Name

106681-4222

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.2

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

303

294

312

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

107

107

Boost pressure

mmHg

805

805

Remarks

Injection at all cylinders.

Injection at all cylinders.

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.6+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

26

23

29

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Injection only at cylinders 1, 3, 4 and 6.

Injection only at cylinders 1, 3, 4 and 6.

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

260

260

280

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-2.5

Boost pressure

kPa

55.3

48.6

62

Boost pressure

mmHg

415

365

465

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(11.2)

Boost pressure

kPa

98

95.3

100.7

Boost pressure

mmHg

735

715

755

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

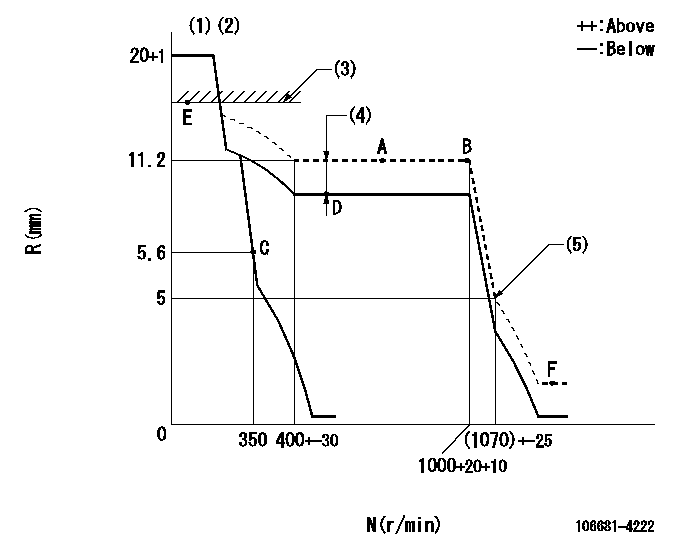

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)The torque control spring does not operate.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

(5)Idle sub spring setting: L1.

----------

K=25 BCL=2.5+-0.1mm L1=5-0.5mm

----------

----------

K=25 BCL=2.5+-0.1mm L1=5-0.5mm

----------

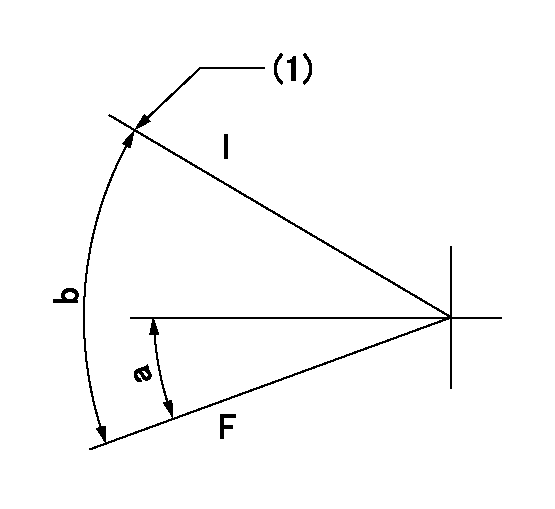

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(20deg)+-5deg b=(29deg)+-5deg

----------

----------

a=(20deg)+-5deg b=(29deg)+-5deg

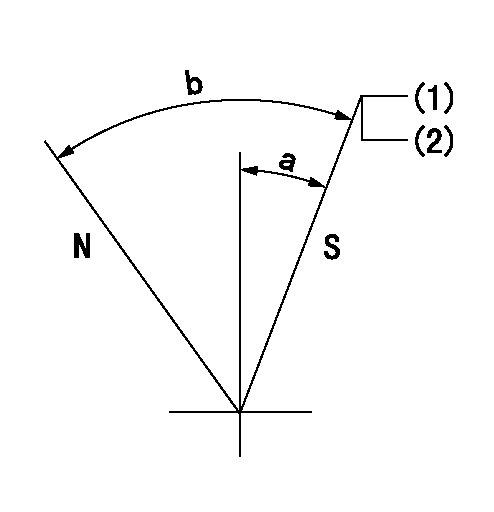

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa, rack position bb

(2)Seal at delivery.

----------

aa=0r/min bb=3-0.5mm

----------

a=27deg+-5deg b=62.5deg+-5deg

----------

aa=0r/min bb=3-0.5mm

----------

a=27deg+-5deg b=62.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

start by:a) remove oil pumpb) remove timing gear coverc) remove flywheel housingd) remove pistons For more detail about removal of main bearings see REMOVE AND INSTALL CRANKSHAFT MAIN BEARINGS. 1. Check each bearing cap (1) for its location on the engine. Each cap has an arrow which is toward the front of the block and a number which gives the location of that cap. Keep each bearing with the correct cap. 2. Remove bearing caps No. 2 through No. 4. Remove thrust plates from No. 3 upper bearing.3. Install one of the flywheel bolts in each end of the crankshaft. Fasten a hoist to the crankshaft as shown. Remove No. 1 and No. 5 main bearing caps. Remove the crankshaft. Weight of the crankshaft is 270 lb. (122 kg).

Be careful not to cause damage to the crankshaft journals when the crankshaft is removed.

4. Remove crankshaft gear (2) with tooling (A).5. Remove dowel and pin from crankshaft with tooling (B).Install Crankshaft

1. Install pin (1) in the crankshaft end until it is extended from the surface .25 .02 in. (6.4 0.5 mm).2. Install dowel (2) until it is extended from the surface .16 .02 in. (4.1 0.5 mm). 3. Heat crankshaft gear (3) to a maximum temperature of 400°F (204°C). Install gear (3) on the crankshaft with groove (4) in alignment with dowel (2).4. Make sure the upper main bearings are clean. Put clean oil on the upper main bearings and journals of the crankshaft.5. Install one of the flywheel bolts in each end of the crankshaft. Fasten a hoist to the crankshaft and put it in position in the block.

Do not cause damage to the crankshaft journals. Make sure the "V" mark on the crankshaft gear is in alignment with the "V" mark on the idler gear.

For more detail about installation of main bearings see REMOVE AND INSTALL CRANKSHAFT MAIN BEARINGS.6. Check the bearing clearances with tool (B).7. Put clean engine oil on the bolts for caps No. 1 and No. 5. Install No. 1 and No. 5 caps with the bolts finger tight. Make sure the arrows on the caps are toward the front of the block. 8. Install thrust plates (5) for the No. 3 upper main bearing. Install the thrust plates with the side that has the identification "Block Side" toward the cylinder block.9. Put clean oil on the bolts for caps No. 2 through No. 4. Install caps No. 2 through No. 4 with the bolts finger tight. Make sure the arrows are toward the front of the block.10. Tighten the cap bolts as follows: a) Tighten the bolts on the tab end of the caps first to a torque of 190 10 lb. ft. (260 14 N m).b) Tighten the bolts on the other end of the caps to a torque of 190 10 lb. ft. (260 14 N m).c) Put a mark across the bolt head and cap. Tighten the bolts opposite the tab end

Be careful not to cause damage to the crankshaft journals when the crankshaft is removed.

4. Remove crankshaft gear (2) with tooling (A).5. Remove dowel and pin from crankshaft with tooling (B).Install Crankshaft

1. Install pin (1) in the crankshaft end until it is extended from the surface .25 .02 in. (6.4 0.5 mm).2. Install dowel (2) until it is extended from the surface .16 .02 in. (4.1 0.5 mm). 3. Heat crankshaft gear (3) to a maximum temperature of 400°F (204°C). Install gear (3) on the crankshaft with groove (4) in alignment with dowel (2).4. Make sure the upper main bearings are clean. Put clean oil on the upper main bearings and journals of the crankshaft.5. Install one of the flywheel bolts in each end of the crankshaft. Fasten a hoist to the crankshaft and put it in position in the block.

Do not cause damage to the crankshaft journals. Make sure the "V" mark on the crankshaft gear is in alignment with the "V" mark on the idler gear.

For more detail about installation of main bearings see REMOVE AND INSTALL CRANKSHAFT MAIN BEARINGS.6. Check the bearing clearances with tool (B).7. Put clean engine oil on the bolts for caps No. 1 and No. 5. Install No. 1 and No. 5 caps with the bolts finger tight. Make sure the arrows on the caps are toward the front of the block. 8. Install thrust plates (5) for the No. 3 upper main bearing. Install the thrust plates with the side that has the identification "Block Side" toward the cylinder block.9. Put clean oil on the bolts for caps No. 2 through No. 4. Install caps No. 2 through No. 4 with the bolts finger tight. Make sure the arrows are toward the front of the block.10. Tighten the cap bolts as follows: a) Tighten the bolts on the tab end of the caps first to a torque of 190 10 lb. ft. (260 14 N m).b) Tighten the bolts on the other end of the caps to a torque of 190 10 lb. ft. (260 14 N m).c) Put a mark across the bolt head and cap. Tighten the bolts opposite the tab end

Have questions with 106681-4222?

Group cross 106681-4222 ZEXEL

Mitsubishi-Heav

106681-4222

INJECTION-PUMP ASSEMBLY