Information injection-pump assembly

BOSCH

F 01G 09U 091

f01g09u091

ZEXEL

106681-3001

1066813001

HINO

220206450B

220206450b

Rating:

Service parts 106681-3001 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236003621A

12.

Open Pre:MPa(Kqf/cm2)

16.7(170)/23.5(240)

14.

NOZZLE

Include in #1:

106681-3001

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 09U 091

f01g09u091

ZEXEL

106681-3001

1066813001

HINO

220206450B

220206450b

Zexel num

Bosch num

Firm num

Name

106681-3001

F 01G 09U 091

220206450B HINO

INJECTION-PUMP ASSEMBLY

K13C-TI K 14CA INJECTION PUMP ASSY PE6P,6PD PE

K13C-TI K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131424-9020

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.67

3.73

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

14

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

337

334

340

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

37.3

37.3

Boost pressure

mmHg

280

280

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.9+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

14

11

17

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

14.3++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

230

225

235

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

900

900

900

Rack position

R1-1.8

Boost pressure

kPa

6.7

4

9.4

Boost pressure

mmHg

50

30

70

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Rack position

R1(14)

Boost pressure

kPa

24

24

24

Boost pressure

mmHg

180

180

180

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

950

Advance angle

deg.

2.5

2.2

2.8

Remarks

Finish

Finish

Test data Ex:

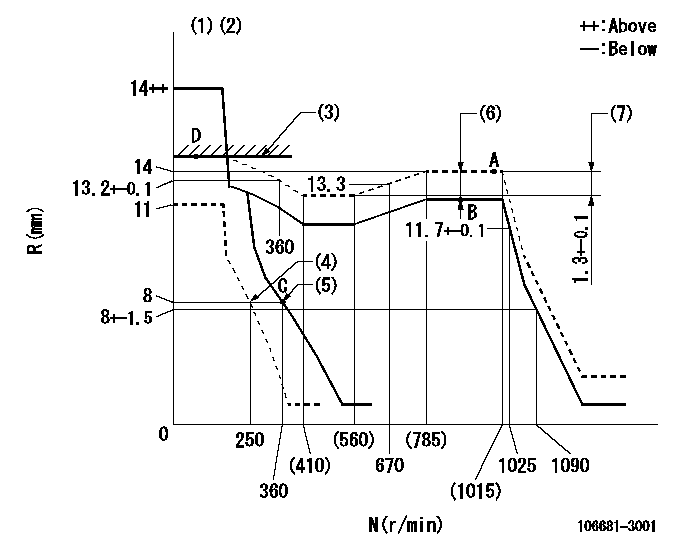

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

(7)Rack difference between N = N1 and N = N2

----------

K=14 BCL=1.8+-0.1mm N1=1000r/min N2=500r/min

----------

----------

K=14 BCL=1.8+-0.1mm N1=1000r/min N2=500r/min

----------

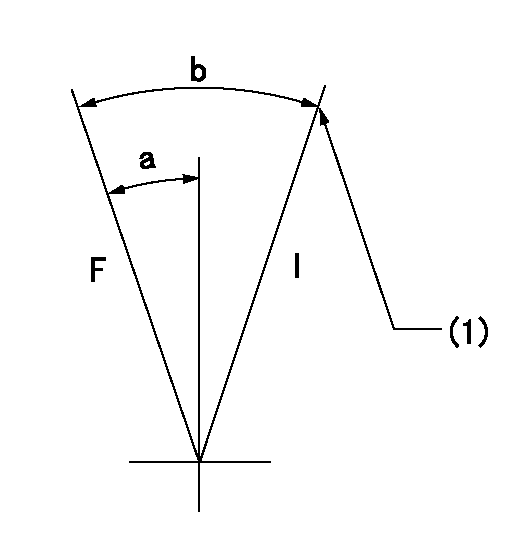

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(5deg)+-5deg b=(27deg)+-5deg

----------

----------

a=(5deg)+-5deg b=(27deg)+-5deg

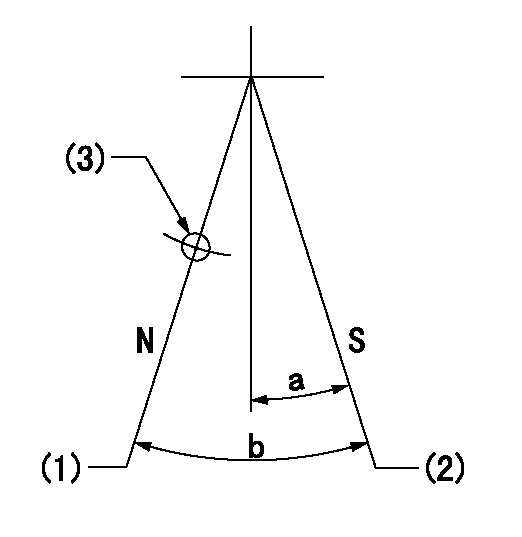

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed aa and rack position bb (to be sealed at delivery)

(3)Use the hole above R = cc

----------

aa=0r/min bb=1-0.5mm cc=20mm

----------

a=10deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm cc=20mm

----------

a=10deg+-5deg b=70deg+-5deg

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(2deg)

----------

aa=14deg

----------

a=(2deg)

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4338" as the Part Number and "7755" as the Group Number. If administered before failure, use "56" as the Warranty Claim Description Code and use "T" as the SIMS Description Code. If administered after failure, use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

Termination Date

June 30, 1999Problem

The 7E7202 Button used in the 7E7205 Rocker Arm Assembly may become separated from the rocker arm when a unit injector sticks during engine operation. Damage to the unit injector may result when the engine is operated with the button separated from the rocker arm.

Affected Product

Model & Identification Number

3606 (8RB298, 8RB585, 8RB590, 8RB591)

3608 (6MC246, 6MC255, 6MC310, 6MC311, 6MC313, 6MC332, 6MC333, 6MC380, 6MC410, 6MC411, 6MC415 , 6MC481, 6MC482, 6MC488-490)

3612 (9RC121, 9RC130, 9RC131, 9RC143, 9RC187, 9RC188)

3616 (1PD24, 1PD82-85, 1PD103, 1PD104, 1PD108-110, 1PD112-115, 1PD117, 1PD119-143 , 1PD148, 1PD154, 1PD156-161, 1PD163, 1PD165, 1PD167, 1PD168, 1PD206 , 1PD211-215, 1PD217, 1PD238, 1PD241-244, 1PD251-261, 1PD264, 1PD267-275 )

Parts Needed

1 - 1514881 Button1 - 5P6031 Wire-LockAction Required

See the attached rework procedure.

Service Claim Allowances

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach.(1-Rework Procedure)Rework Procedure

The following procedure provides instructions to install the 1514881 Button onto the 1514918 Rocker Insert used in the 7E7205 Rocker Arm Assembly for the 3600 Series Engine. The button requires a 5P6031 Lock Wire to secure it to the insert.

Recommended Tooling

- Standard or inch tip screwdriver- 10 or 12 inch multiple position pliers (Channel Locks)- 12 oz Ball Peen Hammer- (2.4 mm) PunchInstallation Of 1514881 Button

1. Remove the 1267473 Rocker Arm Group from the engine and place on a work bench. Use a standard or inch tip screw driver to remove the previous 7E7202 Button and 5P8119 O-Ring by prying between the button and rocker arm. 2. Be sure no damage has occurred to the oil passage in the insert. If damage has occurred it is necessary to replace the insert. A 1514883 Rocker Arm Assembly should be used which includes the 1514881 Button and 1514882 Locking Wire assembled to the insert. 3. If there is no damage to the insert hold the 1514881 Button on the insert using a pair of 10 or 12 inch multiple position pliers. The button has a 2.6 mm (0.10 inch) hole in the side. Make sure the hole in the side of the button is in a position so the wire can be inserted. Insert the wire into the hole. 4. With one person holding the button squarely on the insert with pliers, another person is to hold the wire firmly. Apply pressure on the wire and use

This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4338" as the Part Number and "7755" as the Group Number. If administered before failure, use "56" as the Warranty Claim Description Code and use "T" as the SIMS Description Code. If administered after failure, use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

Termination Date

June 30, 1999Problem

The 7E7202 Button used in the 7E7205 Rocker Arm Assembly may become separated from the rocker arm when a unit injector sticks during engine operation. Damage to the unit injector may result when the engine is operated with the button separated from the rocker arm.

Affected Product

Model & Identification Number

3606 (8RB298, 8RB585, 8RB590, 8RB591)

3608 (6MC246, 6MC255, 6MC310, 6MC311, 6MC313, 6MC332, 6MC333, 6MC380, 6MC410, 6MC411, 6MC415 , 6MC481, 6MC482, 6MC488-490)

3612 (9RC121, 9RC130, 9RC131, 9RC143, 9RC187, 9RC188)

3616 (1PD24, 1PD82-85, 1PD103, 1PD104, 1PD108-110, 1PD112-115, 1PD117, 1PD119-143 , 1PD148, 1PD154, 1PD156-161, 1PD163, 1PD165, 1PD167, 1PD168, 1PD206 , 1PD211-215, 1PD217, 1PD238, 1PD241-244, 1PD251-261, 1PD264, 1PD267-275 )

Parts Needed

1 - 1514881 Button1 - 5P6031 Wire-LockAction Required

See the attached rework procedure.

Service Claim Allowances

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach.(1-Rework Procedure)Rework Procedure

The following procedure provides instructions to install the 1514881 Button onto the 1514918 Rocker Insert used in the 7E7205 Rocker Arm Assembly for the 3600 Series Engine. The button requires a 5P6031 Lock Wire to secure it to the insert.

Recommended Tooling

- Standard or inch tip screwdriver- 10 or 12 inch multiple position pliers (Channel Locks)- 12 oz Ball Peen Hammer- (2.4 mm) PunchInstallation Of 1514881 Button

1. Remove the 1267473 Rocker Arm Group from the engine and place on a work bench. Use a standard or inch tip screw driver to remove the previous 7E7202 Button and 5P8119 O-Ring by prying between the button and rocker arm. 2. Be sure no damage has occurred to the oil passage in the insert. If damage has occurred it is necessary to replace the insert. A 1514883 Rocker Arm Assembly should be used which includes the 1514881 Button and 1514882 Locking Wire assembled to the insert. 3. If there is no damage to the insert hold the 1514881 Button on the insert using a pair of 10 or 12 inch multiple position pliers. The button has a 2.6 mm (0.10 inch) hole in the side. Make sure the hole in the side of the button is in a position so the wire can be inserted. Insert the wire into the hole. 4. With one person holding the button squarely on the insert with pliers, another person is to hold the wire firmly. Apply pressure on the wire and use

Have questions with 106681-3001?

Group cross 106681-3001 ZEXEL

Hino

106681-3001

F 01G 09U 091

220206450B

INJECTION-PUMP ASSEMBLY

K13C-TI

K13C-TI