Information injection-pump assembly

BOSCH

9 400 613 443

9400613443

ZEXEL

106681-3000

1066813000

HINO

220206450A

220206450a

Rating:

Service parts 106681-3000 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236003620A

12.

Open Pre:MPa(Kqf/cm2)

16.7{170}/23.5{240}

14.

NOZZLE

Include in #1:

106681-3000

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 613 443

9400613443

ZEXEL

106681-3000

1066813000

HINO

220206450A

220206450a

Zexel num

Bosch num

Firm num

Name

9 400 613 443

220206450A HINO

INJECTION-PUMP ASSEMBLY

K13C-TI * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

K13C-TI * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Outer diameter - inner diameter - length (mm) mm 8-4-1000

Overflow valve

131424-9020

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.67

3.73

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

14

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

337

334

340

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

37.3

37.3

Boost pressure

mmHg

280

280

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.9+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

14

11

17

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

14.3++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

230

225

235

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

900

900

900

Rack position

R1-1.8

Boost pressure

kPa

6.7

4

9.4

Boost pressure

mmHg

50

30

70

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Rack position

R1(14)

Boost pressure

kPa

24

24

24

Boost pressure

mmHg

180

180

180

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

950

Advance angle

deg.

2.5

2.2

2.8

Remarks

Finish

Finish

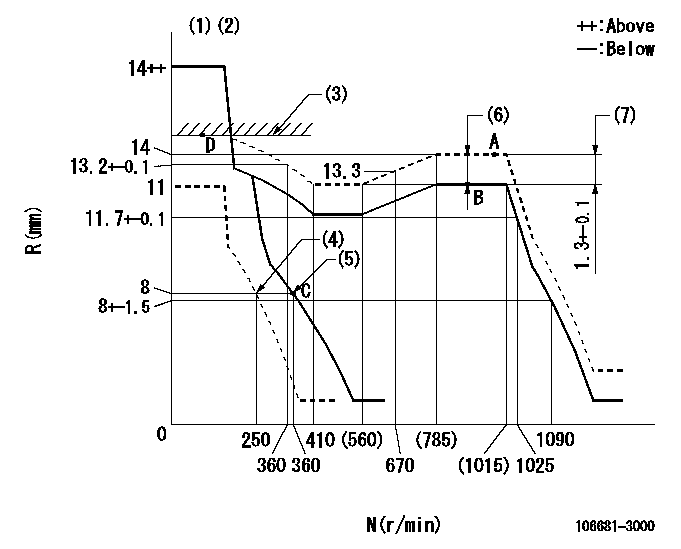

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

(7)Rack difference between N = N1 and N = N2

----------

K=14 BCL=1.8+-0.1mm N1=1000r/min N2=500r/min

----------

----------

K=14 BCL=1.8+-0.1mm N1=1000r/min N2=500r/min

----------

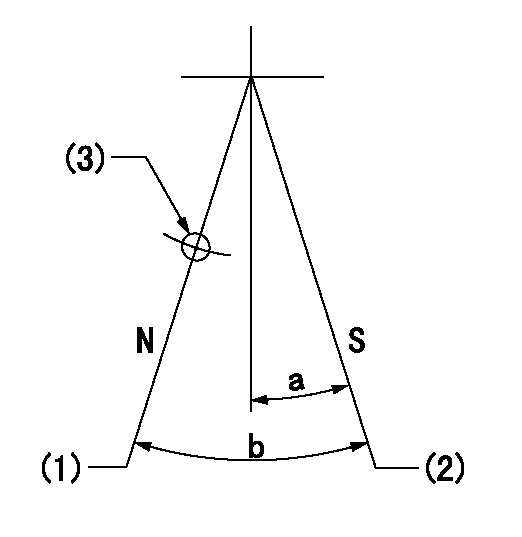

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(5deg)+-5deg b=(27deg)+-5deg

----------

----------

a=(5deg)+-5deg b=(27deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed aa and rack position bb (to be sealed at delivery)

(3)Use the hole above R = cc

----------

aa=0r/min bb=1-0.5mm cc=20mm

----------

a=10deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm cc=20mm

----------

a=10deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(2deg)

----------

aa=14deg

----------

a=(2deg)

Information:

This Program must be administered as soon as possible. When reporting the repair, use "PI3147" as the Part Number, "7751" as the Group Number, "56" as the Warranty Claim Description Code and "T" as the SIMS Description Code. Exception: If the repair is done after failure, use "PI3147" as the Part Number, "7751" as the Group Number, "96" as the Warranty Claim Description Code, and "Z" as the SIMS Description Code.

Refer to your Warranty Bulletin for detailed information with regard to Product Improvement Programs.

Completion Date

November 30, 1998Termination Date

November 30, 1998Problem

Certain 3116 and 3126 2-Valve Engines built from January 28 through February 6, 1998 with CBS heads are suspect to have improper installation of the brass injector sleeve.

Affected Product

Model & Identification Number

3116 (2WG6414-6426 5EN01269, 5EN1270, 5EN1273-1280, 5EN1282 4KG7773-7795 4KG31268NM3029-3043 9ZR771-774 )

Parts Needed

1 - 1192940 Gasket* - 1193061 Sleeve*(as required)Action Required

See the attached procedure.

Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)(2-Rework Procedure)Copy Of Owner Notification For U.S. And Canadian Owners

Rework Procedure

1. Check to see if the head is supplied by CBS or Gosselies. The part number is located on the front of the head on the governor side beside the lifting eye, just above the front cover. In Marine applications, it is best viewed using a light to look between the expansion tank and heat exchanger.If it is a dot-matrix, then the head is from Gosselies. If the part number is stamped, then it is from CBS.

If the head is from Gosselies (dot-matrix part number), then the engine is good and no further work is needed.

If the head is from CBS (Stamped part number) then further inspection/rework is required.

2. If the head is from CBS, remove the valve cover.3. Using a sliding caliper, align the caliper vertically using the edge of the injector spring, measure and record the distance from the timing ledge on the injector to the top face of the head for each cylinder. This measurement will be in the range of 8.39 mm but can vary from engine to engine.4. If the variation from cylinder to cylinder on the same engine is less than 0.40 mm, then the engine is good. Re-install the valve cover. No further inspection is necessary.5. If the variation from cylinder to cylinder on the same engine is greater than 0.40 mm, recheck to verify measurements, if the difference is still greater than 0.40 mm, proceed to Step 6.6. Remove all (6) injectors. Using a depth gage with flat end and a 0.75 inch diameter steel ball dropped into the sleeve, check and record the distance from the top face of the head to the top of the steel ball. This measurement should be 2.583 0.18 inches (65.61 0.46 mm).7. Remove the injector sleeve on any cylinder that the measurement from step 6 is less than 2.565 inch (65.15 mm) and

Refer to your Warranty Bulletin for detailed information with regard to Product Improvement Programs.

Completion Date

November 30, 1998Termination Date

November 30, 1998Problem

Certain 3116 and 3126 2-Valve Engines built from January 28 through February 6, 1998 with CBS heads are suspect to have improper installation of the brass injector sleeve.

Affected Product

Model & Identification Number

3116 (2WG6414-6426 5EN01269, 5EN1270, 5EN1273-1280, 5EN1282 4KG7773-7795 4KG31268NM3029-3043 9ZR771-774 )

Parts Needed

1 - 1192940 Gasket* - 1193061 Sleeve*(as required)Action Required

See the attached procedure.

Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)(2-Rework Procedure)Copy Of Owner Notification For U.S. And Canadian Owners

Rework Procedure

1. Check to see if the head is supplied by CBS or Gosselies. The part number is located on the front of the head on the governor side beside the lifting eye, just above the front cover. In Marine applications, it is best viewed using a light to look between the expansion tank and heat exchanger.If it is a dot-matrix, then the head is from Gosselies. If the part number is stamped, then it is from CBS.

If the head is from Gosselies (dot-matrix part number), then the engine is good and no further work is needed.

If the head is from CBS (Stamped part number) then further inspection/rework is required.

2. If the head is from CBS, remove the valve cover.3. Using a sliding caliper, align the caliper vertically using the edge of the injector spring, measure and record the distance from the timing ledge on the injector to the top face of the head for each cylinder. This measurement will be in the range of 8.39 mm but can vary from engine to engine.4. If the variation from cylinder to cylinder on the same engine is less than 0.40 mm, then the engine is good. Re-install the valve cover. No further inspection is necessary.5. If the variation from cylinder to cylinder on the same engine is greater than 0.40 mm, recheck to verify measurements, if the difference is still greater than 0.40 mm, proceed to Step 6.6. Remove all (6) injectors. Using a depth gage with flat end and a 0.75 inch diameter steel ball dropped into the sleeve, check and record the distance from the top face of the head to the top of the steel ball. This measurement should be 2.583 0.18 inches (65.61 0.46 mm).7. Remove the injector sleeve on any cylinder that the measurement from step 6 is less than 2.565 inch (65.15 mm) and