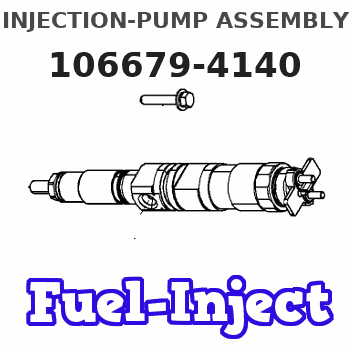

Information injection-pump assembly

BOSCH

9 400 619 663

9400619663

ZEXEL

106679-4140

1066794140

MITSUBISHI-HEAV

3626513210

3626513210

Rating:

Service parts 106679-4140 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106679-4140

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 663

9400619663

ZEXEL

106679-4140

1066794140

MITSUBISHI-HEAV

3626513210

3626513210

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-7420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Opposite to the driving side NO.1

Opposite to the driving side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

14.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

186.5

179.5

193.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.3+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

27

24

30

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.9

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

1.2

0.7

1.7

Timer adjustment_04

Pump speed

r/min

850

Advance angle

deg.

2

1.5

2.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

4

4

4

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(95deg)

----------

----------

a=(95deg)

Information:

Problem

The fuel injectors may fail on certain Challenger 75 Tractors and 3176 Truck Engines.

Affected Product

Model & Identification Number

Challenger 75 (4CJ1-406)

3176 (2YG1-Up; 7LG1-4822)

Parts Needed

Use the following parts in quantities needed to perform repairs. The application of each injector listed is noted. Use remanufactured injectors, unless it is not available.

0R3397 Injector Grp. (4P9510 if remanufactured is not available for 7LG 250-300 HP)0R3398 Injector Grp. (4P9520 if remanufactured is not available for 7LG 325 HP and Challenger 75 4CJ1-406)0R3399 Injector Grp. (4P9610 if remanufactured is not available for 2YG 250-275 HP)0R3400 Injector Grp. (4P9620 if remanufactured is not available for 2YG 300-325 HP)9X7317 Seal (injector tip O-ring)9X7557 Seal (injector upper O-ring)9X7722 Seal (injector lower O-ring)336044 Seal (injector thrust-pad-retaining O-ring)Action Required

See attached Rework Procedure.

Service Claim Allowances

Challenger 75 Tractors

This is a 2.5-hour job. Add 0.2 hours for 1st injector diagnostic test and 0.1 hours for each additional injector test. Add 1.2 hours for first injector sleeve replaced and 0.7 hours for each additional sleeve replaced.

3176 Truck Engines

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

1. Isolate the problem to the individual injector causing the problem. For this program only the failed injector(s) is covered so it is important to isolate the individual injector(s) causing the problem.A. For fuel dilution of the engine oil, first attempt to find the leak by pressurizing the low pressure system with the hand priming pump and the return line blocked off. Visually inspect each injector for leaks. It is also important to inspect the cylinder head casting for leaks around the injector bore, in the hold down bolt holes and along the gallery which crosses the camshaft compartment. If no leaks are found the injectors should be removed and leak tested using the 1U6661 Pop Tester. Drain the fuel manifold by removing the lower plug at the rear of the manifold. Remove the suspect injector(s). Test the injector(s) with the 1U6661 Pop Tester following the procedures in Special Instructions SEHS8867. Be sure to activate the solenoid valve and stroke the injector to create high pressure inside the injector when inspecting the high pressure plug for leaks. The plug is located at the base of the forged body.

The leak-down rate is a measure of plunger clearance leakage and should be checked when looking for fuel leaks.

Some small amount of leakage at the terminal post is permitted. Refer to Service Magazine September 21, 1991 or Truck Engine News October 1991.

B. For misfire or performance problems identification of a failed injector may require duplication of the conditions where the complaint exists. Interviewing the driver for the load and speed conditions where the problem occurs will be helpful. Diagnosis of the problem may require driving the truck with a load on or using a chassis dynomometer if the complaint arises only under loaded conditions.First attempt to diagnose the problem on the engine. Use the ECAP Tool to cut out cylinders under conditions which duplicate the complaint. Noticeable differences in the sound, fuel position (rack),

The fuel injectors may fail on certain Challenger 75 Tractors and 3176 Truck Engines.

Affected Product

Model & Identification Number

Challenger 75 (4CJ1-406)

3176 (2YG1-Up; 7LG1-4822)

Parts Needed

Use the following parts in quantities needed to perform repairs. The application of each injector listed is noted. Use remanufactured injectors, unless it is not available.

0R3397 Injector Grp. (4P9510 if remanufactured is not available for 7LG 250-300 HP)0R3398 Injector Grp. (4P9520 if remanufactured is not available for 7LG 325 HP and Challenger 75 4CJ1-406)0R3399 Injector Grp. (4P9610 if remanufactured is not available for 2YG 250-275 HP)0R3400 Injector Grp. (4P9620 if remanufactured is not available for 2YG 300-325 HP)9X7317 Seal (injector tip O-ring)9X7557 Seal (injector upper O-ring)9X7722 Seal (injector lower O-ring)336044 Seal (injector thrust-pad-retaining O-ring)Action Required

See attached Rework Procedure.

Service Claim Allowances

Challenger 75 Tractors

This is a 2.5-hour job. Add 0.2 hours for 1st injector diagnostic test and 0.1 hours for each additional injector test. Add 1.2 hours for first injector sleeve replaced and 0.7 hours for each additional sleeve replaced.

3176 Truck Engines

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

1. Isolate the problem to the individual injector causing the problem. For this program only the failed injector(s) is covered so it is important to isolate the individual injector(s) causing the problem.A. For fuel dilution of the engine oil, first attempt to find the leak by pressurizing the low pressure system with the hand priming pump and the return line blocked off. Visually inspect each injector for leaks. It is also important to inspect the cylinder head casting for leaks around the injector bore, in the hold down bolt holes and along the gallery which crosses the camshaft compartment. If no leaks are found the injectors should be removed and leak tested using the 1U6661 Pop Tester. Drain the fuel manifold by removing the lower plug at the rear of the manifold. Remove the suspect injector(s). Test the injector(s) with the 1U6661 Pop Tester following the procedures in Special Instructions SEHS8867. Be sure to activate the solenoid valve and stroke the injector to create high pressure inside the injector when inspecting the high pressure plug for leaks. The plug is located at the base of the forged body.

The leak-down rate is a measure of plunger clearance leakage and should be checked when looking for fuel leaks.

Some small amount of leakage at the terminal post is permitted. Refer to Service Magazine September 21, 1991 or Truck Engine News October 1991.

B. For misfire or performance problems identification of a failed injector may require duplication of the conditions where the complaint exists. Interviewing the driver for the load and speed conditions where the problem occurs will be helpful. Diagnosis of the problem may require driving the truck with a load on or using a chassis dynomometer if the complaint arises only under loaded conditions.First attempt to diagnose the problem on the engine. Use the ECAP Tool to cut out cylinders under conditions which duplicate the complaint. Noticeable differences in the sound, fuel position (rack),