Information injection-pump assembly

BOSCH

9 400 617 449

9400617449

ZEXEL

106676-2490

1066762490

MITSUBISHI

ME153460

me153460

Rating:

Cross reference number

BOSCH

9 400 617 449

9400617449

ZEXEL

106676-2490

1066762490

MITSUBISHI

ME153460

me153460

Zexel num

Bosch num

Firm num

Name

106676-2490

9 400 617 449

ME153460 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D24 K

6D24 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.9

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

118.5

115.5

121.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8.5+-0.5

Pump speed

r/min

410

410

410

Each cylinder's injection qty

mm3/st.

15.8

13.4

18.2

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.9)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

118.5

117.5

119.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

117

113

121

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1+0.7)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

124

120

128

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1-0.65

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

112.5

106.5

118.5

Fixing the lever

*

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

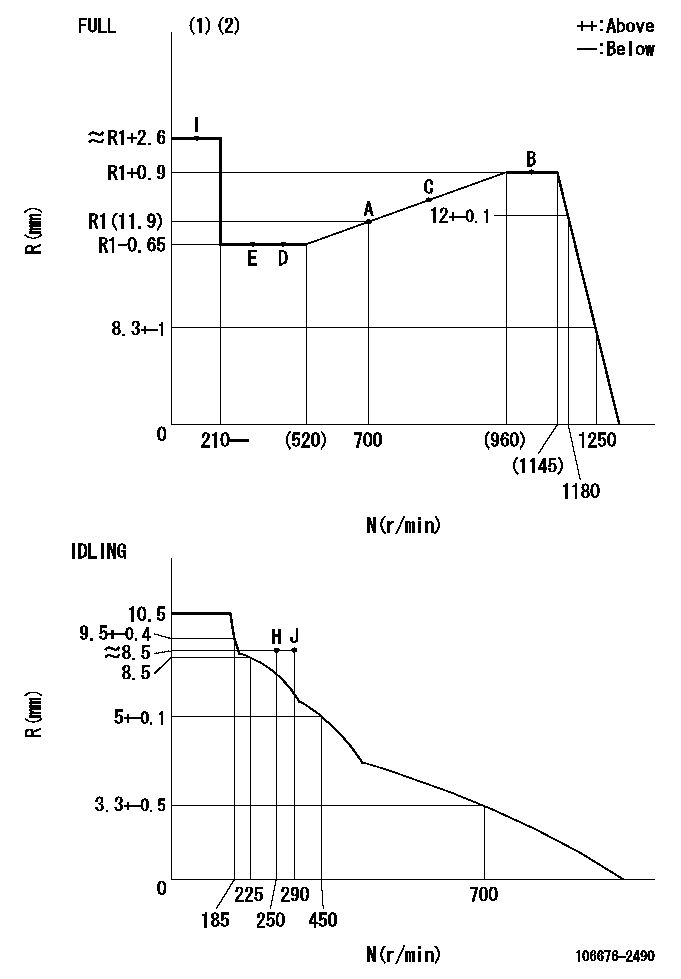

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=AE41

----------

----------

T1=AE41

----------

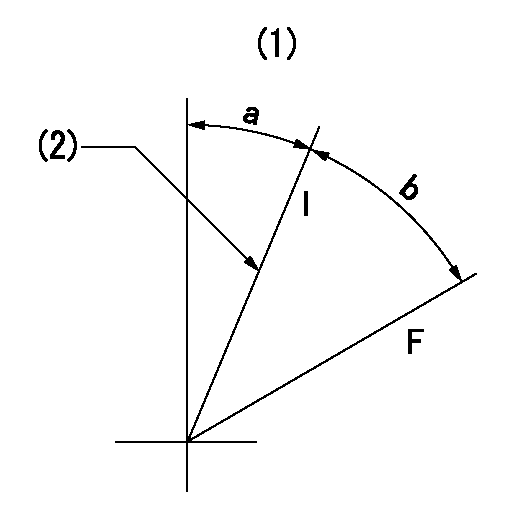

Speed control lever angle

F:Full speed

I:Idle

(1)Viewed from feed pump side.

(2)Stopper bolt set position 'H'

----------

----------

a=30deg+-5deg b=(36.5deg)+-3deg

----------

----------

a=30deg+-5deg b=(36.5deg)+-3deg

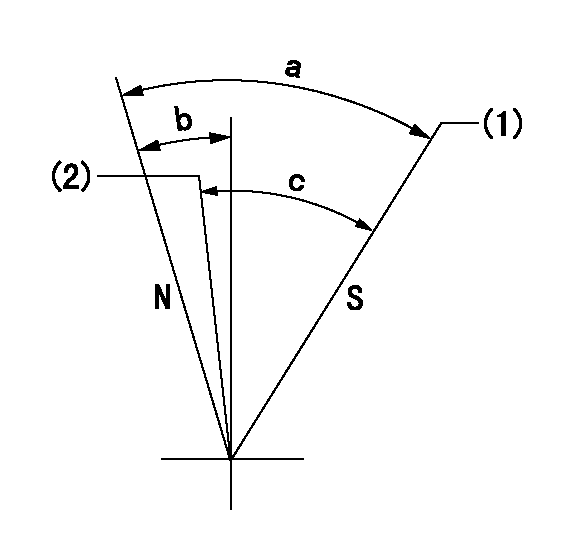

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At pump speed aa and rack position bb, set the stopper bolt. (Confirm non-injection.)

(2)Normal engine position (Rack position corresponding to cc)

----------

aa=1100r/min bb=3.5+-0.3mm cc=18mm

----------

a=40deg+-5deg b=25.5deg+-5deg c=(31deg)+-5deg

----------

aa=1100r/min bb=3.5+-0.3mm cc=18mm

----------

a=40deg+-5deg b=25.5deg+-5deg c=(31deg)+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=7.6+-0.1mm

----------

----------

N1=325r/min Ra=7.6+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(8deg)

----------

aa=12deg

----------

a=(8deg)

Information:

If there has been a previous repair, part age/hours will apply. Retain a copy of the previous repair invoice in the dealer's records for audit purposes, and specify repair date and machine hours in the "Additional Comments" section of the warranty claim.

Dealer to perform most economical repair.

Description____________________________SMCS Code___Hours

Wash___________________________________1091-074 ___0.2

Inner fender __________________________7252-010 ___0.2

R&I DPF _______________________________108F-010 ___1.2

program ECM - program DPF serial # ,

ASH reset, factory passwords __________1901-591 ___0.2

Test after Repair _____________________108F-030 ___0.2

This letter is to be performed during a recommended ash service as stated in Media number SEBU8087. Ash cleaning is a part of the recommended maintenance of the engine, customer is responsible for the labor required to remove and install the DPF.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

1. Wash debris from Diesel Particulate Filter (DPF) as necessary.

Image1.1.1

2. Remove the Fender (A): Loosen and remove the nuts and bolts from the fender of the truck. Retain the fender and fasteners for reuse. Refer to Image 1.1.1.

Image1.2.1

3. Remove the Step (B): Loosen and remove fasteners from the step of the truck. Retain the step and fasteners for reuse. Refer to Image 1.2.1.

Image1.3.1

Image1.3.2

4. Remove the Pipe Clamps: Loosen and remove clamps from the Inlet Pipe (C)& Outlet Pipe (D) of the DPF?s. Refer to Image 1.3.1 & Image 1.3.2

Image1.4.1

5. Remove tubes (E) and sensor box mounting bolts (F) to unplug sensor box connection. Refer to Image 1.4.1.

Image1.5.1

6. Remove DPF mounting bolts: Loosen and remove fasteners from the mounting of the DPF. Retain the mounting and fasteners for reuse. No jack will be used to hold DPF, DPF is supported by air tank brackets. Properly support DPF until it rests on the bracket. Refer to Image 1.5.1.

Image1.6.1

7. Slide the DPF forward and remove. Remove the CGI pipe (G) after the DPF has been removed. Refer to Image 1.6.1.

Image 1.7.1 shows the chassis after the welded DPF has been removed.

Image1.7.1

Image1.7.2

8. Install the Clamped DPF with mounting bolts (reuse the bolts). Install the new 330-4036 CGI Pipe for Group 1 & Group 2 with the 304-3048 Clamp. Check Inlet, Outlet and CGI pipes alignment, mounting brackets should be aligned with OEM brackets.

Refer OEM guidelines for connecting Inlet & CGI connections.

Image 1.7.2 shows the clamped DPF after it has been installed in the chassis.

9. Install the step and fender that were removed in Step 2 and Step 3.

10. Reset the engine ash model. Refer Media Number RENR9705.

11. Start the engine and use CAT ET to ensure that the status parameter Diesel Particulate Trap #1 Differential Pressure has a value greater than zero. Also ensure status parameters Diesel Particulate Trap #1 Intake Temperature, and Diesel Particulate Trap #1 Outlet Temperature show reasonable values and increase with the rising exhaust temperatures.

Have questions with 106676-2490?

Group cross 106676-2490 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

106676-2490

9 400 617 449

ME153460

INJECTION-PUMP ASSEMBLY

6D24

6D24